OUTSTANDING!!! Love the color match too!

-

Vehicle-Trailer ClassifiedsStolen Vehicles/Parts FJ40 | BJ40 BJ42 | FJ43 | BJ44 | FJ45 | FJ45LV | HJ47 FJ55 | FJ56 FJ60 | FJ62 | BJ60 | HJ61 BJ74 | VZJ95 | HZJ75 | KZJ90 FJ80 | FZJ80 | LX450 | HDJ81 UZJ100 | LX470 VDJ200 | LX570 GX460 | GX470 LC250 | GX550 FJ Cruiser Stout | Hilux | Minitruck Tacoma Surf | 4Runner Tundra | Sequoia Other Vehicles Trailers | Campers | RVs

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt on 80 Series Tire Carrier Compatible with Factory Bumper

- Thread starter GGM

- Start date

-

- Tags

- fzj80 swingout tire carrier

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #102

People were asking for videos of the opening and closing of the tire carrier. Follow the link below to see the quick videos. Notice the latch has a locking feature to prevent unintended openings.

drive.google.com

drive.google.com

Shared Video - Google Drive

drive.google.com

drive.google.com

snowglobe

SILVER Star

I thing a PS swingout could attach to the DS swingout.

Add an extension plate to the DS swingout “latching area“ which the PS swingout could latch onto.

The user would have to latch close the DS swingout first, then latch close the PS swingout onto that.

The PS swingout could hold jerry cans or whatever.

Add an extension plate to the DS swingout “latching area“ which the PS swingout could latch onto.

The user would have to latch close the DS swingout first, then latch close the PS swingout onto that.

The PS swingout could hold jerry cans or whatever.

snowglobe

SILVER Star

Alternatively, make a jerry can mount that sits over the tire. I don’t know how much more weight the DS swingout could handle, though. The swingout itself looks overbuilt, but the swingout mount itself may not be able to handle much more torque when the swingout is open. It would also be yet more weight on the DS side, and up higher.I thing a PS swingout could attach to the DS swingout.

Add an extension plate to the DS swingout “latching area“ which the PS swingout could latch onto.

The user would have to latch close the DS swingout first, then latch close the PS swingout onto that.

The PS swingout could hold jerry cans or whatever.

snowglobe

SILVER Star

An alternative latch point for a PS swingout could be something which fits into a standard trailer hitch - It shouldn’t preclude using the hitch, though. Maybe a combination of hitch rattle stopper and latch point for the PS swingout, attached by the same U bolt system used by hitch tightener anti rattle stabilizers.I thing a PS swingout could attach to the DS swingout.

Add an extension plate to the DS swingout “latching area“ which the PS swingout could latch onto.

The user would have to latch close the DS swingout first, then latch close the PS swingout onto that.

The PS swingout could hold jerry cans or whatever.

People were asking for videos of the opening and closing of the tire carrier. Follow the link below to see the quick videos. Notice the latch has a locking feature to prevent unintended openings.

Shared Video - Google Drive

drive.google.com

Thank you SO much for posting these! You’ve really built a solid, too-notch product!!

I JUST ORDERED MINE!!!! I’m flippin stoked!!!!!!

Probably should have inquired about a military discount as an active duty service member. Nonetheless, I am happy to pay full price for such an awesome product that I’ve waited a long time for.

Probably should have inquired about a military discount as an active duty service member. Nonetheless, I am happy to pay full price for such an awesome product that I’ve waited a long time for.

- Thread starter

- #108

A few people have installed there carriers and ran into a small issue. It looks like Lexus has larger plastics on the corners. The bottom of the spindle on the frame mount may hit the plastic on land cruisers. That corner will need to be cut or ground down to fit inside the plastic like the picture below.

I'm really sorry about this and will start cutting this edge off before it ships. I appreciate the feedback and want to make this as easy as possible for the end user.

I'm really sorry about this and will start cutting this edge off before it ships. I appreciate the feedback and want to make this as easy as possible for the end user.

This is what it'll look like if you don't trim that corner, and the cap is difficult to re-install and I couldn't get all the screws back in place. Pretty sure I'm going to remove mine and cut the corner down and touch up the powder coat with paint.

Couple pictures from today's install. Powder coated to match the factory trim. Turned out really nice! Working on a license plate mount, this one will do for now.

View attachment 3165461

View attachment 3165462

View attachment 3165463

View attachment 3165464

Hey GGM, mind sharing the color of powder you used? Also, have you decided if/when your going to offer weld it yourself kits?Couple pictures from today's install. Powder coated to match the factory trim. Turned out really nice! Working on a license plate mount, this one will do for now.

View attachment 3165461

View attachment 3165462

View attachment 3165463

View attachment 3165464

- Thread starter

- #111

The powder coater didn't tell me the exact color. Yours may vary. I would recommend talking with your local powder coater to see how they can help.

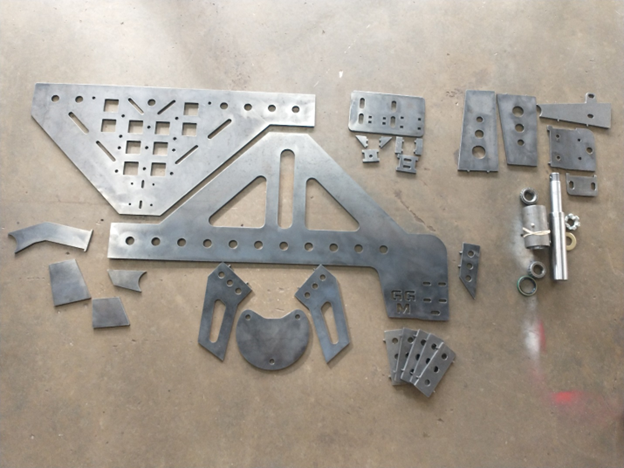

I will be offering a weld it yourself kit, the price (as of now) will be $640 shipped. I need to gather some pictures of all the pieces, but it is currently on the website.

I want to do a write-up/instructions as well for the DIY kit so that you know what you are getting into. Bear with me for when I can get that done.

I will be offering a weld it yourself kit, the price (as of now) will be $640 shipped. I need to gather some pictures of all the pieces, but it is currently on the website.

I want to do a write-up/instructions as well for the DIY kit so that you know what you are getting into. Bear with me for when I can get that done.

Last edited:

- Thread starter

- #112

Here's a link to the DIY listing, Ill update it when I get some pictures.

www.generalgreenmanufacturing.com

www.generalgreenmanufacturing.com

DIY 80 Series Bolt on Tire Carrier | GGM

All the contents of our bolt on kit just not welded. You do the fun part of welding! This kit is designed to be as easy as possible to weld together but it will require a competent welder and basic tools.

www.generalgreenmanufacturing.com

www.generalgreenmanufacturing.com

- Thread starter

- #113

I made a write up on the weld it yourself kit here:

forum.ih8mud.com

forum.ih8mud.com

Here's a link to download the instructions from our site.

www.generalgreenmanufacturing.com

www.generalgreenmanufacturing.com

Weld it Yourself 80 Series Tire Carrier Assembly Instructions

To not crowd things up, I wanted to make a write up on welding together our Weld it Yourself 80 Series Tire Carrier kit. These instructions are for a driver side mount. A few things are mirrored for the passenger side version. All the pieces included with the kit minus the hardware. A couple...

forum.ih8mud.com

forum.ih8mud.com

Here's a link to download the instructions from our site.

Free Downloads | General Green Manufacturing Llc

Instructions, helpful files and media

www.generalgreenmanufacturing.com

www.generalgreenmanufacturing.com

Last edited:

@80 Life @snowglobe Also in Colorado, would love to see it!!

Well, I just figured out where any year-end work bonus money will be going.

- Thread starter

- #116

Here's the prototype table addition. Some things may change but I'm liking the initial design. It's 16" wide and 8 3/4" deep. When folded up it sticks out about 1 1/4". Has a push button latch. Let me know what you think!

Loving it. Would like a bigger table. But beggars can’t be choosers. I’m sure it would be easy enough for one to create their own if they chose to. But if it’s to support someone who’s doing the most to produce quality products for our rigs, then im all for it.Here's the prototype table addition. Some things may change but I'm liking the initial design. It's 16" wide and 8 3/4" deep. When folded up it sticks out about 1 1/4". Has a push button latch. Let me know what you think!

View attachment 3170612View attachment 3170613View attachment 3170615

View attachment 3170601

I honestly think the size is pretty decent considering it being a flip down accessory. Super impressed by the durability based on the pics.Loving it. Would like a bigger table. But beggars can’t be choosers. I’m sure it would be easy enough for one to create their own if they chose to. But if it’s to support someone who’s doing the most to produce quality products for our rigs, then im all for it.

GGM, any idea on a price? Thanks!!!

- Thread starter

- #120

I'll work on a price tomorrow!I honestly think the size is pretty decent considering it being a flip down accessory. Super impressed by the durability based on the pics.

GGM, any idea on a price? Thanks!!!

Currently, no there is nothing to stop the swinging portion, I packed a lot of features into this design but I haven't found a easy and economical solution to a stop. HOWEVER, there are holes all over this thing. If you would like to add a strut,limit strap or something similar there's many features you could work off of. I may come up with an add on for this at a later time.neato, also is there anything that holds the swingout open so it can't swing shut? And if you go with the table will there still be a provision for mounting anything along that back panel?

Some customers have used gas struts successfully.

The table covers up a lot of the mounting features except for the top. I don't think it's possible to work around that.

Similar threads

- Replies

- 0

- Views

- 667

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)