curious... what do you mean?I've been seeing alot of people using the Milwaukee packout system in their rigs. If I developed some goodies that use that system would anyone be interested? Suggestions and request?

-

Vehicle-Trailer ClassifiedsStolen Vehicles/Parts FJ40 | BJ40 BJ42 | FJ43 | BJ44 | FJ45 | FJ45LV | HJ47 FJ55 | FJ56 FJ60 | FJ62 | BJ60 | HJ61 BJ74 | VZJ95 | HZJ75 | KZJ90 FJ80 | FZJ80 | LX450 | HDJ81 UZJ100 | LX470 VDJ200 | LX570 GX460 | GX470 LC250 | GX550 FJ Cruiser Stout | Hilux | Minitruck Tacoma Surf | 4Runner Tundra | Sequoia Other Vehicles Trailers | Campers | RVs

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt on 80 Series Tire Carrier Compatible with Factory Bumper (1 Viewer)

- Thread starter GGM

- Start date

-

- Tags

- fzj80 swingout tire carrier

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #302

Milwaukee tools has developed a interlocking system to attach/secure toolboxes and things. It's a pretty neat system to keep things organized. Some companies are making panels kinda like molle panels to attach those boxes to their rig.curious... what do you mean?

If you Google it or go to the section in home Depot you'll see what I'm talking about.

What I'm purposing is making mounts that use that system for the 80 series.

Thanks Matt,

looking forward to what you develop.

looking forward to what you develop.

well this seems like a good idea I am sure we can find some folks with milaukee packouts locallyI've been seeing alot of people using the Milwaukee packout system in their rigs. If I developed some goodies that use that system would anyone be interested? Suggestions and request?

- Thread starter

- #305

Mean while, I finalized the limit linkage. I will write up instructions tomorrow morning. If you ordered a retrofit they will ship out tomorrow.

Also, I started playing with ideas for the "wings" corner armor.

Also, I started playing with ideas for the "wings" corner armor.

- Thread starter

- #306

Update!

Installation instructions have been added to the website. The swingout installation instructions have also been updated to include the Limit Linkage.

You can see them here

To everyone that ordered the retrofit let me know how it works out for you!

Installation instructions have been added to the website. The swingout installation instructions have also been updated to include the Limit Linkage.

You can see them here

To everyone that ordered the retrofit let me know how it works out for you!

What about a mount on the quarter panel? Would be much trickier, but it is somewhere most of us aren't utilizing space enough. Just spitballing here, there might not be enough space for the packouts. I added pictures of some other products that are similar to get an idea of what can be done with the quarter panel of an 80 and also pictures of a truck bed to show how they are mounting Milwaukee Packout's horizontallyI've been seeing alot of people using the Milwaukee packout system in their rigs. If I developed some goodies that use that system would anyone be interested? Suggestions and request?

- Thread starter

- #309

I appreciate that! I'll look into it.View attachment 3277952

I was procrastinating at work and got some more dimensions. Little janky, but should be fairly accurate.

What about a mount on the quarter panel? Would be much trickier, but it is somewhere most of us aren't utilizing space enough. Just spitballing here, there might not be enough space for the packouts. I added pictures of some other products that are similar to get an idea of what can be done with the quarter panel of an 80 and also pictures of a truck bed to show how they are mounting Milwaukee Packout's horizontally

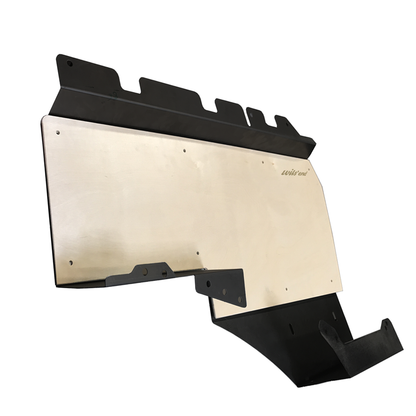

The bottom two pics are of the wits end mount.

Quarter Panel Mount, 80 Series- right (batch 6 pre-order)

Quarter Panel Mount, 80 Series- right (batch 4 pre-order)(QPM-1)

Ohhhhh! I was about to pull the trigger on ordering the rear carrier but if you're setting corner armor up, I ight have to wait! Or, would this be an add-on to the existing set up?Mean while, I finalized the limit linkage. I will write up instructions tomorrow morning. If you ordered a retrofit they will ship out tomorrow.

Also, I started playing with ideas for the "wings" corner armor.

View attachment 3275060View attachment 3275062

View attachment 3275059

View attachment 3275061

- Thread starter

- #312

The current plan is the "wings" will work with the swingouts.

Ohhhhh! I was about to pull the trigger on ordering the rear carrier but if you're setting corner armor up, I ight have to wait! Or, would this be an add-on to the existing set up?

Awesome, so it can be a follow up purchase? Great!The current plan is the "wings" will work with the swingouts.

I'd be interested in Milwaukee pack out stuff.

Hey there Matt, I am about to purchase the TCAM but I am concerned about weight. Say if I add accessories to the TCAM, will it be too heavy if I'm running a 37 inch tire. I know the max limit for the tire carrier is 37's for width, but what about weight? Your product is pretty hefty but I wouldn't want to over load it.

- Thread starter

- #317

Hey there Matt, I am about to purchase the TCAM but I am concerned about weight. Say if I add accessories to the TCAM, will it be too heavy if I'm running a 37 inch tire. I know the max limit for the tire carrier is 37's for width, but what about weight? Your product is pretty hefty but I wouldn't want to over load it.

We have not determined what the maximum load and failure of the system would be. The ability to pinpoint the failure numbers for dynamic, static and cyclical loading is beyond our current capability.

While our products are designed and constructed to be tough and capable... Each user is responsible for using good judgment and common sense in their particular installation and should be comfortable with their choices in using the TCAM and tire carrier.

- Thread starter

- #318

Wanted to share an idea a customer had on locating the spindle on the plastic. Not sure what his name is on MUD but maybe he'll chime in.

He installed the frame mount, then aligned a plumb bob to the center of the spindle. Remove the frame mount and reinstalled the bumper and boom! You can mark the location for the hole needed in the plastic. GREAT IDEA!

He installed the frame mount, then aligned a plumb bob to the center of the spindle. Remove the frame mount and reinstalled the bumper and boom! You can mark the location for the hole needed in the plastic. GREAT IDEA!

We have not determined what the maximum load and failure of the system would be. The ability to pinpoint the failure numbers for dynamic, static and cyclical loading is beyond our current capability.

While our products are designed and constructed to be tough and capable... Each user is responsible for using good judgment and common sense in their particular installation and should be comfortable with their choices in using the TCAM and tire carrier.

This was a concern as mine as well. I have the TCAM installed on mine and had hung a 4.5 gallon fuelpax to it. There is minor wiggling coming from the carrier, with my 34” tire mounted. Not enough wiggle to worry me, but then again, I had not filled my fuelpax completely to 4.5 gallons. And if anyone has any experience with extra fuel, you know 4.5 gallons is HEAVY. I chose to err on the side of caution. Will be using my TCAM for other options besides fuel.

I wish I’d been smart enough to do this. Very happy with how mine turned out but good lawd—measuring 20 times before drilling once was nerve wracking.Wanted to share an idea a customer had on locating the spindle on the plastic. Not sure what his name is on MUD but maybe he'll chime in.

He installed the frame mount, then aligned a plumb bob to the center of the spindle. Remove the frame mount and reinstalled the bumper and boom! You can mark the location for the hole needed in the plastic. GREAT IDEA!

View attachment 3318054

Similar threads

- Replies

- 0

- Views

- 678

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)