Hi Albert.

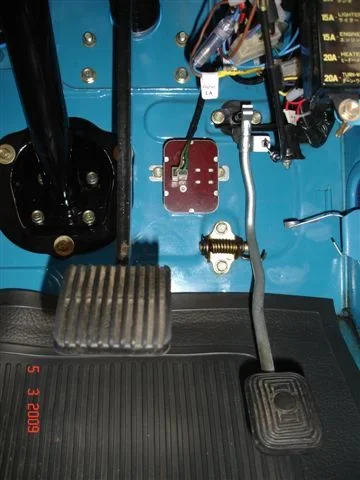

Here's my OEM strap between my motor and frame:

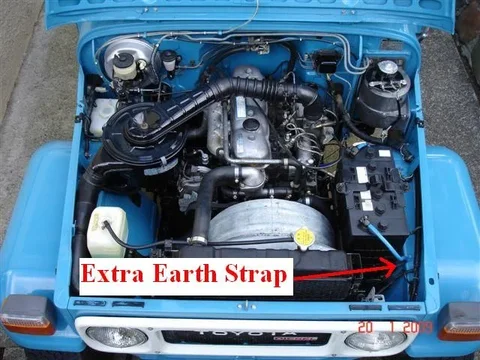

And here is an extra strap that I ran from where my OEM battery-earth-strap attaches to my guard. (The other end connects to a bolt on my timing cover.) .... And adding this extra earthing-lead DEFINITELY increased my cranking RPM to make starting easier.

Here's my OEM strap between my motor and frame:

And here is an extra strap that I ran from where my OEM battery-earth-strap attaches to my guard. (The other end connects to a bolt on my timing cover.) .... And adding this extra earthing-lead DEFINITELY increased my cranking RPM to make starting easier.

)

)