- Thread starter

- #141

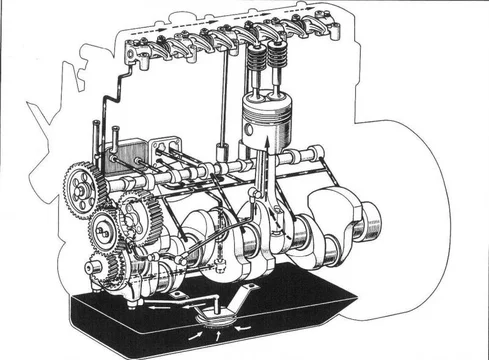

I requested Jose go ahead and order new BEBs because they are not an expensive item. Not sure how I will direct him but... and I know many will cringe, I think I will take the 'fix what is obviously broken' route at this time. That is not to say it will be done carelessly and without thought. I spent an hour yesterday discussing what could be tested, checked and measured during/after the beb replacement. Some of the ideas were to try and isolate the flow of oil to the problem area, front beb, and determine if it is getting oil. Visually inspect, where possible, the lubrication system circuit, check the oil strainer and pipe, check the oil flow to the top of the engine. I'd like to see the engine turned over by hand post repair and do an inspection. I will request an oil pressure test post repair. The mechanic will also measure the tolerances and let me know if we are within specs post repair. Any suggestions?

What was also discussed was that this problem is not likely something that happened only after I purchased the vehicle. From the day the vehicle had a shipping inspection in El Salvador until today there have been 246 Km put on the vehicle. I may be put on 160 km since I purchased it. One of the first things I did was change the oil and filter using a synthetic made for diesel engine oil, a brand and weight recommended on mud/manual. I did not change the diffs, or trans. I greased all the fittings I was aware of at the time. I also replaced a brake line that was put together with electrical tape and replaced a clutch line that was in poor shape. Oh, I bleed the entire brake fluid and installed DOT3 maybe DOT4, I'd have to check. The brakes feel pretty good for drums all around, and I have not inspected them yet.

From my point of view, and noted in a lost post, the engine looked as if it has not been tinkered with on the bottom side. From my best pictures, I can see that the edges of most of the bolts are still very straight, almost new condition. This was also my first impression looking at the underside for the first time. From what I could feel inside one or two cylinders, they felt smoother than I would have expected for an old vehicle. Almost like they were polished smooth. Also from my impressions of the entire vehicle, she looks worn in but not too bad. Buttons still have their logos and the steering wheel is polished but not overly worn, the horn works too. All the exposed parts that could have come loose or hit a rock over time have been messed with. Transmission covers removed and new RTV sealant installed, very recently, see album picts. The engine does not look like it has been removed from the vehicle. The trans looks as it has, my guess to replace the clutch, service, who knows? The exhaust for example, is original but the brackets, pipes have all been adjusted.

I guess what I am saying is that I have some faith that the vehicle was not heavily abused, accident damaged, etc. This is leading me to conclude to fix what is broken until I know where this is all headed.

Thoughts? ideas?

BTW attached is a picture of the vehicle at the US Embassy in El Salvador. Notice the cardboard box under the oil pan collecting the oil during the week or so the PO had it stored there before shipping to the US

What was also discussed was that this problem is not likely something that happened only after I purchased the vehicle. From the day the vehicle had a shipping inspection in El Salvador until today there have been 246 Km put on the vehicle. I may be put on 160 km since I purchased it. One of the first things I did was change the oil and filter using a synthetic made for diesel engine oil, a brand and weight recommended on mud/manual. I did not change the diffs, or trans. I greased all the fittings I was aware of at the time. I also replaced a brake line that was put together with electrical tape and replaced a clutch line that was in poor shape. Oh, I bleed the entire brake fluid and installed DOT3 maybe DOT4, I'd have to check. The brakes feel pretty good for drums all around, and I have not inspected them yet.

From my point of view, and noted in a lost post, the engine looked as if it has not been tinkered with on the bottom side. From my best pictures, I can see that the edges of most of the bolts are still very straight, almost new condition. This was also my first impression looking at the underside for the first time. From what I could feel inside one or two cylinders, they felt smoother than I would have expected for an old vehicle. Almost like they were polished smooth. Also from my impressions of the entire vehicle, she looks worn in but not too bad. Buttons still have their logos and the steering wheel is polished but not overly worn, the horn works too. All the exposed parts that could have come loose or hit a rock over time have been messed with. Transmission covers removed and new RTV sealant installed, very recently, see album picts. The engine does not look like it has been removed from the vehicle. The trans looks as it has, my guess to replace the clutch, service, who knows? The exhaust for example, is original but the brackets, pipes have all been adjusted.

I guess what I am saying is that I have some faith that the vehicle was not heavily abused, accident damaged, etc. This is leading me to conclude to fix what is broken until I know where this is all headed.

Thoughts? ideas?

BTW attached is a picture of the vehicle at the US Embassy in El Salvador. Notice the cardboard box under the oil pan collecting the oil during the week or so the PO had it stored there before shipping to the US