I put the Dobinsons heavy 1.75"/2" lift with their 'yellow' shocks and I am on 33 Fallken AT3W. I have had absolutely no issues by NOT doing anything with caster correction. I have driven about 10k miles with this. The only thing I had to do with this lift is to extend the breather tubes for the diffs. Before you do the lift and the work you should bring it to an alignment shop to get a baseline of where you are now, do the lift, drive it to test, and then bring it back to see the difference. The main decision should really be based on YOUR driving and your feelings with it.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any caster correction needed for 2" lift?

- Thread starter 96eighty

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #22

Here are my OME 2.5* bushings after 10 years and 110K miles. They were most likely due for a change several miles ago?

Switched to OEM bushings and 5* castor plates.

Front DS issues are haunting!

devo

View attachment 2891394

View attachment 2891395

How much lower do the drop brackets hang compared to the stock no brackets?

COYS

SILVER Star

I put the Dobinsons heavy 1.75"/2" lift with their 'yellow' shocks and I am on 33 Fallken AT3W. I have had absolutely no issues by NOT doing anything with caster correction.

What were your L and R caster values with lift and no caster correction?

@devo,

Looks like you have the dobinson 5 degree plates and I'm curious if you been able to get enough clearance to stop your tie rod from bumping the radius arms?

I've done a few grinding sessions now and am bump/clank free in smooth driving but I get contact on both/either side on bumps. I'm planning to grind more on the arms and maybe even mod the plates for less axle rotation to get the clearance I need but I'm curious what your experience has been or if you have pictures/tips for how you gained the clearance you need, if you did.

Thanks!

Looks like you have the dobinson 5 degree plates and I'm curious if you been able to get enough clearance to stop your tie rod from bumping the radius arms?

I've done a few grinding sessions now and am bump/clank free in smooth driving but I get contact on both/either side on bumps. I'm planning to grind more on the arms and maybe even mod the plates for less axle rotation to get the clearance I need but I'm curious what your experience has been or if you have pictures/tips for how you gained the clearance you need, if you did.

Thanks!

@jpoole

Well my experience is that it sucks. That Dobinsons sells these plates and not a word that there will be issues with the tie rods hitting the radius arms. If Dobinsons would have told me this was inevitable I would have gone a different direction. One option I have is to throw these things in the trash the other is to grind. Grinding is what Dobinsons recommended to me after the fact. If a solution is Delta then thats too much $$$$. I want to talk with @landtank to find out if with his plates there is the same issue. I didn’t go with LandTank because of the need to weld and I don’t weld. So now I’m in a pickle as to what to do?

If you make a mod to change your axle rotation won’t that decrease your castor and increase your pinion angle? Are you running a Dobinsons 3.5” lift?

devo

Well my experience is that it sucks. That Dobinsons sells these plates and not a word that there will be issues with the tie rods hitting the radius arms. If Dobinsons would have told me this was inevitable I would have gone a different direction. One option I have is to throw these things in the trash the other is to grind. Grinding is what Dobinsons recommended to me after the fact. If a solution is Delta then thats too much $$$$. I want to talk with @landtank to find out if with his plates there is the same issue. I didn’t go with LandTank because of the need to weld and I don’t weld. So now I’m in a pickle as to what to do?

If you make a mod to change your axle rotation won’t that decrease your castor and increase your pinion angle? Are you running a Dobinsons 3.5” lift?

devo

I have to get those readings. I haven't yet because I haven't experienced anything wrong.What were your L and R caster values with lift and no caster correction?

COYS

SILVER Star

I have to get those readings. I haven't yet because I haven't experienced anything wrong.

@devo

Before I waste a bunch of space with reasons why lets just say I'm doing my caster correction bass-ackwards. Now for the long story:

My wife tried to drive my 80 over the holidays and found it stressful/challenging. I've been planning for new springs and then caster correction but the sliders took a long time to get in, I'm moving slowly, etc. With young kids/etc. I typically do one or two projects on the 80 a year. For many months I've had washers and the Dob. 5 degree plates and a welder on hand. I knew that the results from the washers would better match my correction needs but I decided that the Dob. plates looked like max caster and easiest to install/undo so I put them in to see how the truck responded so that I could adjust course from there. I knew I should wait til lift was finalized but I wanted to try to make the truck safer to drive now.

I've ground the arms about as much as I'm comfortable with and I still get contact so I'm considering grinding the plates and reducing caster, switching to landtanks lower lift plates or installing the washer mod. Both the washer mod and landtank plates will grind higher up in to the arm mounts on the axle though and I do like how minimal the cuts were for the Dob. plates. Of course if I mod the Dob plates I'll have to cut higher into the axle/arm mounts as well.

At this point my 80 should be around 5.5 caster based on my last alignment/caster check and what the plates report to adjust. I've read different numbers on how much caster you'll get per how far your rotate the axle and I'm not sure that the Dob. plates are a full 5 degrees but they may be. My 80 is around 21" wheel center to flare bottom on all 4 corners and I plan to lift at least another inch based on pretty extensive reading on the springs I plan to install (850/860 OME) and my weight level (sliders only, no bumpers, 2nd battery, roof rack, platform, etc.)... My rough estimate is that I'll loose another 1.5 degree or more of caster which would put me at 4 degrees. 4 degrees is my target unless there are issues (arm / tie rod contact, shaft growls, spring twist). If I mod the plates for clearance and loose a degree of correction but stop the clanking, then end up at 3 degrees that seems perfectly acceptable and based on my experience driving at .5ish for a year I'm guessing that anything over 2ish should feel pretty good on my 80.

So, in short pretty bass ackwards way to do things but I was curious how throwing max plate correction would play out and I'm glad to know. I've had minimal shaft vibes and pretty bad arm/tie rod contact from the 5 degree plates. I had read a lot here about the various plates before installing these and there was very little info on the Dob plates and arm/rod contact. That's part of why I asked you here, to get more info out there for others. There's a lot that I like about the Dob plates but based on my front axle at least there is an issue with tie-rod and radius arm clearance. I'd love to see pictures of how far into the arms someone ground to stop the clanging. I think they may have had to go through the upper/horizontal section of the arm beam. The top surface of the I-Beam, that I'm struggling to think of a better word for. I took that down by about 1/3rd thickness on the outer edge and think it's still plenty strong but I'd rather roll back caster than grind further at this point.

I increasingly appreciate the benefits of the Delta arms but I prefer to tinker and adjust/spend slowly for now. If I had the sliders and new springs installed already I'd consider the arms but I'm just not going to spend the $ without alignment numbers and a more finalized setup to guide the selection. I'll grind on some $150 plates and clearance my arms (that may get replaced anyway) though, to make it safer if/when my wife needs to drive again!

Hope some part of that long response was helpful. Let me know if you learn anything of interest as you proceed.

Before I waste a bunch of space with reasons why lets just say I'm doing my caster correction bass-ackwards. Now for the long story:

My wife tried to drive my 80 over the holidays and found it stressful/challenging. I've been planning for new springs and then caster correction but the sliders took a long time to get in, I'm moving slowly, etc. With young kids/etc. I typically do one or two projects on the 80 a year. For many months I've had washers and the Dob. 5 degree plates and a welder on hand. I knew that the results from the washers would better match my correction needs but I decided that the Dob. plates looked like max caster and easiest to install/undo so I put them in to see how the truck responded so that I could adjust course from there. I knew I should wait til lift was finalized but I wanted to try to make the truck safer to drive now.

I've ground the arms about as much as I'm comfortable with and I still get contact so I'm considering grinding the plates and reducing caster, switching to landtanks lower lift plates or installing the washer mod. Both the washer mod and landtank plates will grind higher up in to the arm mounts on the axle though and I do like how minimal the cuts were for the Dob. plates. Of course if I mod the Dob plates I'll have to cut higher into the axle/arm mounts as well.

At this point my 80 should be around 5.5 caster based on my last alignment/caster check and what the plates report to adjust. I've read different numbers on how much caster you'll get per how far your rotate the axle and I'm not sure that the Dob. plates are a full 5 degrees but they may be. My 80 is around 21" wheel center to flare bottom on all 4 corners and I plan to lift at least another inch based on pretty extensive reading on the springs I plan to install (850/860 OME) and my weight level (sliders only, no bumpers, 2nd battery, roof rack, platform, etc.)... My rough estimate is that I'll loose another 1.5 degree or more of caster which would put me at 4 degrees. 4 degrees is my target unless there are issues (arm / tie rod contact, shaft growls, spring twist). If I mod the plates for clearance and loose a degree of correction but stop the clanking, then end up at 3 degrees that seems perfectly acceptable and based on my experience driving at .5ish for a year I'm guessing that anything over 2ish should feel pretty good on my 80.

So, in short pretty bass ackwards way to do things but I was curious how throwing max plate correction would play out and I'm glad to know. I've had minimal shaft vibes and pretty bad arm/tie rod contact from the 5 degree plates. I had read a lot here about the various plates before installing these and there was very little info on the Dob plates and arm/rod contact. That's part of why I asked you here, to get more info out there for others. There's a lot that I like about the Dob plates but based on my front axle at least there is an issue with tie-rod and radius arm clearance. I'd love to see pictures of how far into the arms someone ground to stop the clanging. I think they may have had to go through the upper/horizontal section of the arm beam. The top surface of the I-Beam, that I'm struggling to think of a better word for. I took that down by about 1/3rd thickness on the outer edge and think it's still plenty strong but I'd rather roll back caster than grind further at this point.

I increasingly appreciate the benefits of the Delta arms but I prefer to tinker and adjust/spend slowly for now. If I had the sliders and new springs installed already I'd consider the arms but I'm just not going to spend the $ without alignment numbers and a more finalized setup to guide the selection. I'll grind on some $150 plates and clearance my arms (that may get replaced anyway) though, to make it safer if/when my wife needs to drive again!

Hope some part of that long response was helpful. Let me know if you learn anything of interest as you proceed.

Last edited:

As far as caster plates go, there are mine and then everyone else's. Even though the shape of other's are different the result is the same. So comparing my plates with the Dobinson's, my plates provide more caster correction and you don't need to grind the arms. While the extra correction is nice it's actually needed to align the pinion so a DC shaft can be used. That's important because it's the best way to ensure that there won't be any drive line vibrations.@jpoole

Well my experience is that it sucks. That Dobinsons sells these plates and not a word that there will be issues with the tie rods hitting the radius arms. If Dobinsons would have told me this was inevitable I would have gone a different direction. One option I have is to throw these things in the trash the other is to grind. Grinding is what Dobinsons recommended to me after the fact. If a solution is Delta then thats too much $$$$. I want to talk with @landtank to find out if with his plates there is the same issue. I didn’t go with LandTank because of the need to weld and I don’t weld. So now I’m in a pickle as to what to do?

If you make a mod to change your axle rotation won’t that decrease your castor and increase your pinion angle? Are you running a Dobinsons 3.5” lift?

devo

Regardless how you get there as far as what type of method you use to correct for caster, at higher lifts you run the risk of drive line vibrations which can be uncontrollable regardless of which type of drive shaft you use. I chose the use of a DC shaft and incorporated that into my design.

And as far as I know all plate systems should be stitched welded in place for safety reasons.

My plates are a stand alone solution. You tell me what the distance from the hub center to flare is and I'll tell you what products of mine to use and what the expected caster result will be.@landtank ,

Thanks for chiming in. When I looked into a DC ds I was told that my ds angle of 10* was not enough to warrant a DC ds and that my pinion angle needed to be 0* ?

So down the the worm hole I go!

devo

The 10* comment might be true, I don't know, but the Dobinson plates do fall short on rotating the axle enough to properly align for a DC shaft.

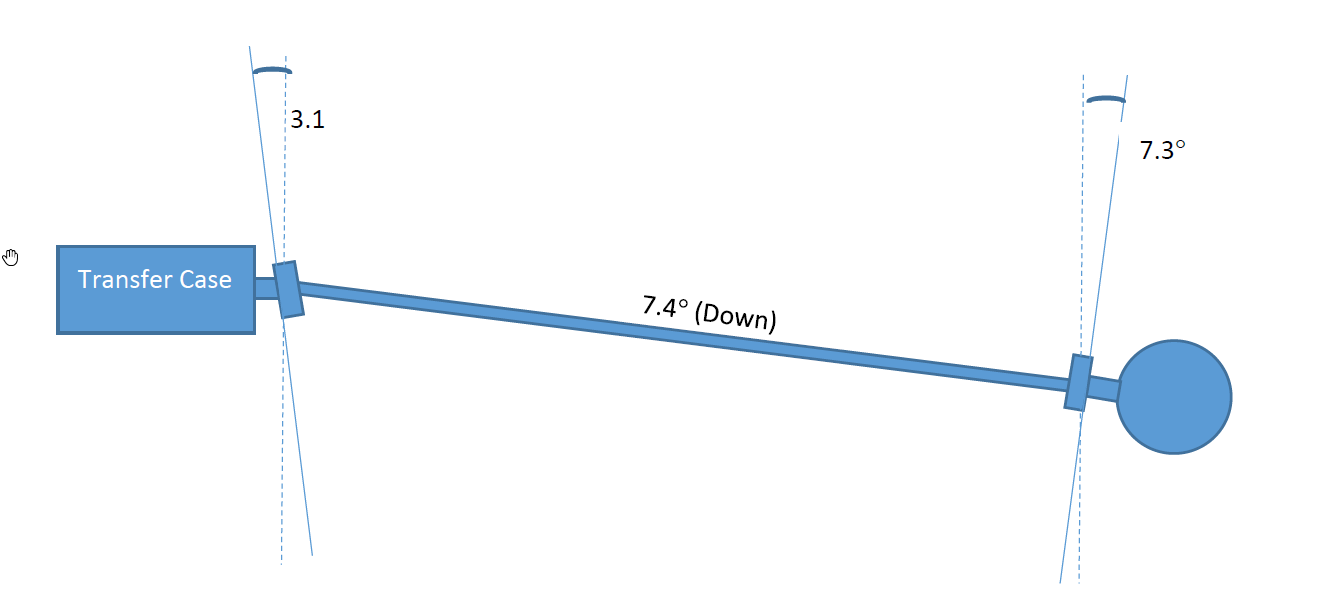

I used Rick's plates (the smaller version) on my (confirmed) 3" lift. The rotation on the axle measured out at 7.3° and the driveshaft at 7.4°. With these angles my set up was more or less perfect for a DC driveshaft. With the smaller plates my caster came in 2.0° which is on the low side but still inside OEM specifications. The truck handled perfect and no noticeable vibrations.

77mustard40

SILVER Star

Are you running a DC DS? I’ve got the Landtank 2.5’s as well and Delta‘s rear panhard lift bracket. I now have a higher lift after swapping in some gently used Dobs 146-VT’s / 147-VT’s and my fronts are 23.75“ and 23.85”. I added the IMS shocks and the ride is super, I don’t have vibes but do have the occasional low growl if the throttle is feathered just right on a high speed downhill. Truck still drives really nice even though I might be a little caster light; would love to solve the growl though. Then I’d be done, swear.I used Rick's plates (the smaller version) on my (confirmed) 3" lift. The rotation on the axle measured out at 7.3° and the driveshaft at 7.4°. With these angles my set up was more or less perfect for a DC driveshaft. With the smaller plates my caster came in 2.0° which is on the low side but still inside OEM specifications. The truck handled perfect and no noticeable vibrations.

View attachment 2893253

Hey @devo,

I just finished a 5 hour drive with the 80 and the increased caster without the clanking was great. I do think I heard tie-rod to arm contact on one slow speed bump that I hit while turning pretty hard, but that was the only possible clank so it's very close now, in that department at least I was at .5ish degree caster before plates, then 5.5ish and now I roughly estimate that I'm around 4 degrees and it drives better than it has since I got the 80

I was at .5ish degree caster before plates, then 5.5ish and now I roughly estimate that I'm around 4 degrees and it drives better than it has since I got the 80  I'm thinking I may try to go with less lift than I was planning to try to end up around 3 degrees per my rough math, when the new springs are in, well that or I'll lift more and go with new arms. I don't see how I could have gotten the full 5 degrees of correction out of these plates given how much I had to grind off the arms and then the plates to stop the clanking.

I'm thinking I may try to go with less lift than I was planning to try to end up around 3 degrees per my rough math, when the new springs are in, well that or I'll lift more and go with new arms. I don't see how I could have gotten the full 5 degrees of correction out of these plates given how much I had to grind off the arms and then the plates to stop the clanking.

I've marked the first photo below with the grind points that I used to reduce the caster adjustment. I increased the depth of the lower notch that the front arm bolt passes through and then took the same amount of metal out of the upper caster plate bolt hole. I don't have a photo of the plates / axles unbolted after the adjustment so basically I removed metal where the red dots are in the first photo.

My rough measurement was that the plates originally moved the front arm bolt down about 15mm. The tie rod moves a similar amount to the front bolt though it's not exact. For a number of reasons I went with a 30% caster adjustment reduction and added a 5mm cut to the bottom of the axle mounts. I used calipers to confirm the same spacing on each of the four front/lower bolt holes and I ground slowly with a lot of test fits. The second photo shows how the plates fit on the axle with the 5mm removed. You can see that to take more out will start to require a lot more grinding on the plates as they'll hit the axle tubes.

I was able to make this adjustment without lifting the tires off the ground. First I loosened the rear/chassis-side nut on the arms a little so that the arms could then be unbolted from the axle and dropped down. Just remove/lower one arm at a time and for the arm that you remove it's likely that the axle will push forward a bit, though that could vary. I put a small ratchet strap from frame to axle to allow me to pull the axle back to where it aligned for re-installing the bolts after the grinding was done.

On the inside of the plates, particularly the outer passenger side plate, I had to grind around the inner edge so that the plate didn't hit the welds around the axle/arm mounts. Once you are able to get the plate adjusted for less caster you want to make sure it also sits flush against the side of the axle mount and that it's not high-centered and rocking where it makes contact with a weld.

After you drop the arm down from the axle you can put the plates back on with just the rear bolt. That makes it easy to swing the plate up to help you keep your grinding to a minimum and in line with how the plate will seat. Once the bottom plate notch is where you want it you then open up the top bolt hole until the lower edges of the axle mount and the plate line up. Reinstall the first set of plates with snug bolts that are just loose enough to slide when you remove the other arm, then things will settle into the new position. When both plates are adjusted and the 80s parked back on flat ground you can torque all of the bolts back up.

Paint where you grind to avoid rust and as mentioned above you'll likely want to weld the plates on to some extent once you get them where you want them.

I just finished a 5 hour drive with the 80 and the increased caster without the clanking was great. I do think I heard tie-rod to arm contact on one slow speed bump that I hit while turning pretty hard, but that was the only possible clank so it's very close now, in that department at least

I've marked the first photo below with the grind points that I used to reduce the caster adjustment. I increased the depth of the lower notch that the front arm bolt passes through and then took the same amount of metal out of the upper caster plate bolt hole. I don't have a photo of the plates / axles unbolted after the adjustment so basically I removed metal where the red dots are in the first photo.

My rough measurement was that the plates originally moved the front arm bolt down about 15mm. The tie rod moves a similar amount to the front bolt though it's not exact. For a number of reasons I went with a 30% caster adjustment reduction and added a 5mm cut to the bottom of the axle mounts. I used calipers to confirm the same spacing on each of the four front/lower bolt holes and I ground slowly with a lot of test fits. The second photo shows how the plates fit on the axle with the 5mm removed. You can see that to take more out will start to require a lot more grinding on the plates as they'll hit the axle tubes.

I was able to make this adjustment without lifting the tires off the ground. First I loosened the rear/chassis-side nut on the arms a little so that the arms could then be unbolted from the axle and dropped down. Just remove/lower one arm at a time and for the arm that you remove it's likely that the axle will push forward a bit, though that could vary. I put a small ratchet strap from frame to axle to allow me to pull the axle back to where it aligned for re-installing the bolts after the grinding was done.

On the inside of the plates, particularly the outer passenger side plate, I had to grind around the inner edge so that the plate didn't hit the welds around the axle/arm mounts. Once you are able to get the plate adjusted for less caster you want to make sure it also sits flush against the side of the axle mount and that it's not high-centered and rocking where it makes contact with a weld.

After you drop the arm down from the axle you can put the plates back on with just the rear bolt. That makes it easy to swing the plate up to help you keep your grinding to a minimum and in line with how the plate will seat. Once the bottom plate notch is where you want it you then open up the top bolt hole until the lower edges of the axle mount and the plate line up. Reinstall the first set of plates with snug bolts that are just loose enough to slide when you remove the other arm, then things will settle into the new position. When both plates are adjusted and the 80s parked back on flat ground you can torque all of the bolts back up.

Paint where you grind to avoid rust and as mentioned above you'll likely want to weld the plates on to some extent once you get them where you want them.

No problem @devo and the 5 mm reduction took about 1 hr 45 mins start to finish including a test drive. I wouldn't have gone this direction from the start but compared to my other options after the plates were on and arms clearanced a good bit this was the easiest way to get rolling without clanking for me.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)