EDIT - Motor failed again after less than a minute of use in Moab. This refresh did not pan out, time to get a replacement.

My 8274-50 was starting to get a bit weak after 5 years on the front of my 62, a number of submersions and countless miles of salty winter roads with no cover (note to self, make a cover). I decided to pull it off, go through it and add fill and drain plugs to keep the geartrain happy. I was expecting to find a water/oil mix in it, but when I broke the case apart, it looked beautiful inside.

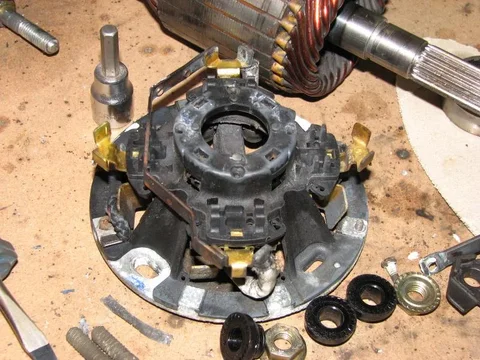

The motor, on the other hand, is crusty. Both bearings are toast.

Both bearings are toast.

Given that a decent replacement is going to cost at least $200, I decided to see if I could tear it down, clean it up and get it back in shape. If it works, I plan to add some cross-flow venting to the motor housing inspired by the setup for the dizzy on my 62. If it doesn't work, I'm only out some time and several cans of wobbly pop. It's my first time tearing into an electric motor, so off we go. Let me know if I've got my terminology wrong.

Motor seems to be a Bosch that is made in Brazil.

A peak inside the case.

The rotor looks to be in decent shape other than some scuffing where it rubbing against a couple of the steel pieces that core the field coils. I thought this would be due to corrosion behind the steel pieces, but there wasn't any of significance to see once things were torn down.

Just some of the loose crap that I was able to knock out before tearing it down.

My 8274-50 was starting to get a bit weak after 5 years on the front of my 62, a number of submersions and countless miles of salty winter roads with no cover (note to self, make a cover). I decided to pull it off, go through it and add fill and drain plugs to keep the geartrain happy. I was expecting to find a water/oil mix in it, but when I broke the case apart, it looked beautiful inside.

The motor, on the other hand, is crusty.

Both bearings are toast.

Both bearings are toast.Given that a decent replacement is going to cost at least $200, I decided to see if I could tear it down, clean it up and get it back in shape. If it works, I plan to add some cross-flow venting to the motor housing inspired by the setup for the dizzy on my 62. If it doesn't work, I'm only out some time and several cans of wobbly pop. It's my first time tearing into an electric motor, so off we go. Let me know if I've got my terminology wrong.

Motor seems to be a Bosch that is made in Brazil.

A peak inside the case.

The rotor looks to be in decent shape other than some scuffing where it rubbing against a couple of the steel pieces that core the field coils. I thought this would be due to corrosion behind the steel pieces, but there wasn't any of significance to see once things were torn down.

Just some of the loose crap that I was able to knock out before tearing it down.

Last edited:

Guess I'll check with the multi meter to see if there is a short I can identify and if not call it dead.

Guess I'll check with the multi meter to see if there is a short I can identify and if not call it dead.