So I picked up my 92 earlier this year off of CL. Rig hailed from WA originally and seems to have been taken care of. From what I can tell she was used as a family hauler/camping/kayaking rig. A few maintenance records were in the glove box and included some Napa receipts and whatnot. Nothing exciting. Mileage at the time I bought it was right around 187k. Paint is great except for the smallest clearcoat fade on the upper tailgate. Body/frame is straight. Interior is excellent. And most importantly, NO rust - except for some exhaust crust, but I don't count that.

When I first got brought her home.

Did a lot of the initial PM things, mainly fluids and small stuff, and then just drove the beast as is. The more I drove it, the more I started to love the 3FE for its simplicity and character. To me, the FJ80 has a lot of soul. Anyway, I started noticing some things that were going to need to be addressed in short order. A couple of small 'seeps' from underneath, a radiator that was starting to blow a seam up top, some beginnings of fray on the belts, brittle hoses, weak battery, etc...

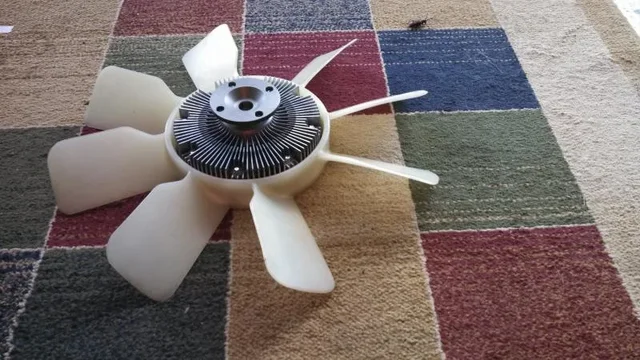

So put speed dials in for CDan and Beno and started collecting box after box of Mr. T goodies. Got a radiator, water pump, fan clutch, hoses, belts, studs, bolts, more hoses, gaskets, hose clamps, oil seal, plugs, wires, rotor, cap and finally some more hoses. And then some factory shocks. Thanks Dan and Beno! It took couple of months but I finally got all my loot put together. My goal was to dig in for a few days and do it all at once.

I was able to arrange 4 days off work. More importantly, and I know a lot of you guys will appreciate this, I was given the all clear from the Mrs. to disappear to the garage without any expectation of being an involved father or husband. WOOT!

My entire goal with this is to have a reliable truck that will last me a long time. I've never tackled anything like this before and I'm hoping that by doing all this myself I'll learn some things AND save a lot of $$$.

...I'm also hoping to earn a full . Right now I'm a 1/2

. Right now I'm a 1/2  , unless I've been drinking too much and then I'm a five

, unless I've been drinking too much and then I'm a five  .

.

Tear down begins. I first went to a local A/C shop and had all of the R12 sucked out of the system so that I could remove my condenser. I wanted easy access. I only found ONE shop in town who was certified and willing to work on R12.

Don't worry, the pics will get better than this.

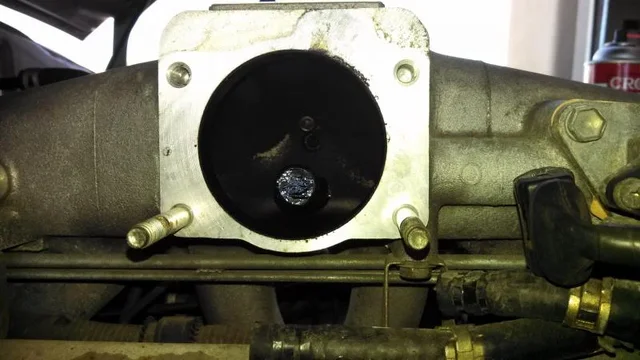

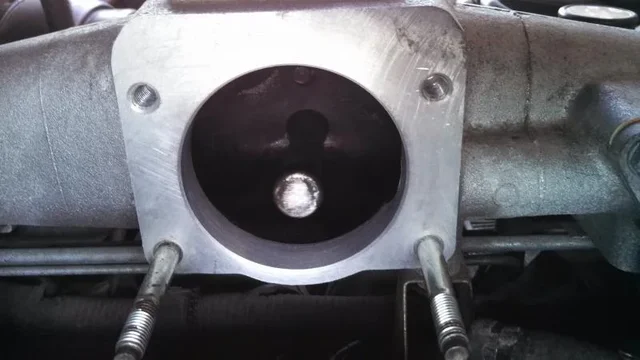

I have a feeling this picture will be worth the proverbial thousand words.

Jason

When I first got brought her home.

Did a lot of the initial PM things, mainly fluids and small stuff, and then just drove the beast as is. The more I drove it, the more I started to love the 3FE for its simplicity and character. To me, the FJ80 has a lot of soul. Anyway, I started noticing some things that were going to need to be addressed in short order. A couple of small 'seeps' from underneath, a radiator that was starting to blow a seam up top, some beginnings of fray on the belts, brittle hoses, weak battery, etc...

So put speed dials in for CDan and Beno and started collecting box after box of Mr. T goodies. Got a radiator, water pump, fan clutch, hoses, belts, studs, bolts, more hoses, gaskets, hose clamps, oil seal, plugs, wires, rotor, cap and finally some more hoses. And then some factory shocks. Thanks Dan and Beno! It took couple of months but I finally got all my loot put together. My goal was to dig in for a few days and do it all at once.

I was able to arrange 4 days off work. More importantly, and I know a lot of you guys will appreciate this, I was given the all clear from the Mrs. to disappear to the garage without any expectation of being an involved father or husband. WOOT!

My entire goal with this is to have a reliable truck that will last me a long time. I've never tackled anything like this before and I'm hoping that by doing all this myself I'll learn some things AND save a lot of $$$.

...I'm also hoping to earn a full

. Right now I'm a 1/2

. Right now I'm a 1/2  , unless I've been drinking too much and then I'm a five

, unless I've been drinking too much and then I'm a five  .

. Tear down begins. I first went to a local A/C shop and had all of the R12 sucked out of the system so that I could remove my condenser. I wanted easy access. I only found ONE shop in town who was certified and willing to work on R12.

Don't worry, the pics will get better than this.

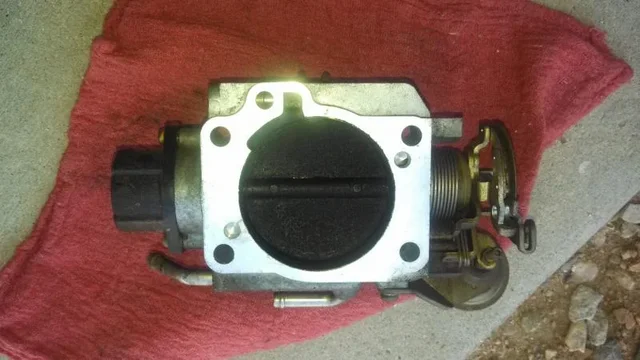

I have a feeling this picture will be worth the proverbial thousand words.

Jason

Last edited:

isn't as allowing as your

isn't as allowing as your