ok so i have started on my intake manifold modification and i am after some ideas on how i should supply the air into the manifold.

1.should i just go directly into the centre as per standard arangement

2. should i put 2 inlets into the manifold say above no2 and no5 cylinders

what your thoughts

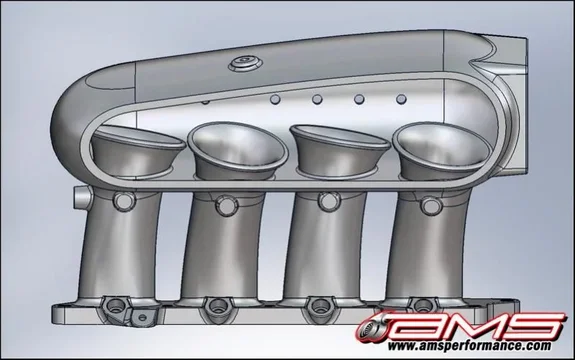

here are some pics

or something like this

1.should i just go directly into the centre as per standard arangement

2. should i put 2 inlets into the manifold say above no2 and no5 cylinders

what your thoughts

here are some pics

or something like this