Hello,

I recently had my belts changed in a pinch and noticed the shop (that I will not be going back to) ran the belts on the wrong side of the idler pulley below the alternator. Based on all the diagrams I have seen, the belt should go outside the pulley and not inside.

Can I just re-run the belts the proper way or should I buy new belts since I’m worried they might be stretched now?

How it looks right now (wrong):

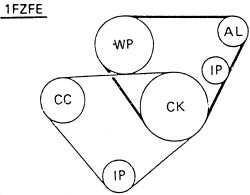

how it’s supposed to look:

I recently had my belts changed in a pinch and noticed the shop (that I will not be going back to) ran the belts on the wrong side of the idler pulley below the alternator. Based on all the diagrams I have seen, the belt should go outside the pulley and not inside.

Can I just re-run the belts the proper way or should I buy new belts since I’m worried they might be stretched now?

How it looks right now (wrong):

how it’s supposed to look: