- Thread starter

- #241

Well there goes another chunk of money.........

Part Number Part Description QTY Tracking Number

Carrier: Est. Arrival

ACC-170072 CONNECTOR 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-G5210 HEI POWER PIGTAIL 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-400500 DISTRIBUTOR CLAMP 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-901011 FORD OIL PRIMER 1/4" 1 1Z1XW7200387540188

UPS: 3-4 bus. days

ARP-430-3501 SB & BB CHEVY SS 12PT STARTER 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-250000-1 SBC MECHANICAL FUEL PUMP 80GPH 1 1Z1XW7200387540188

UPS: 3-4 bus. days

LOK-TC-1000U THROTTLE CABLE 1 1Z1XW7200387540188

UPS: 3-4 bus. days

TRD-2047 KIT CARB STUD 2 IN 1 1Z1XW7200387540188

UPS: 3-4 bus. days

MSD-5562 STREET FIRE WIRE 1 1Z1XW7200387540188

UPS: 3-4 bus. days

I just noticed I somehow ordered a ford oil pump primer tool to prime a chevy And I have already primed it but with a chunk of a distributor so it only oiled the driver side of the valve train

And I have already primed it but with a chunk of a distributor so it only oiled the driver side of the valve train

Part Number Part Description QTY Tracking Number

Carrier: Est. Arrival

ACC-170072 CONNECTOR 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-G5210 HEI POWER PIGTAIL 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-400500 DISTRIBUTOR CLAMP 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-901011 FORD OIL PRIMER 1/4" 1 1Z1XW7200387540188

UPS: 3-4 bus. days

ARP-430-3501 SB & BB CHEVY SS 12PT STARTER 1 1Z1XW7200387540188

UPS: 3-4 bus. days

SUM-250000-1 SBC MECHANICAL FUEL PUMP 80GPH 1 1Z1XW7200387540188

UPS: 3-4 bus. days

LOK-TC-1000U THROTTLE CABLE 1 1Z1XW7200387540188

UPS: 3-4 bus. days

TRD-2047 KIT CARB STUD 2 IN 1 1Z1XW7200387540188

UPS: 3-4 bus. days

MSD-5562 STREET FIRE WIRE 1 1Z1XW7200387540188

UPS: 3-4 bus. days

I just noticed I somehow ordered a ford oil pump primer tool to prime a chevy

And I have already primed it but with a chunk of a distributor so it only oiled the driver side of the valve train

And I have already primed it but with a chunk of a distributor so it only oiled the driver side of the valve train

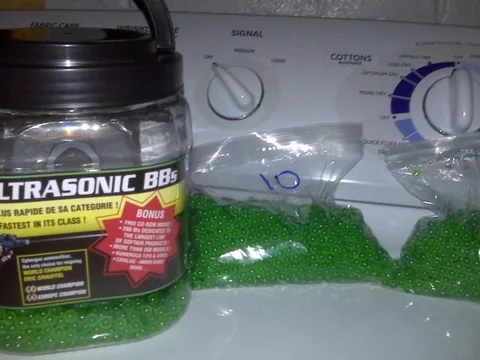

I used my electric reloading scales and converted to grains. 10 ounces is something like 4375 grains or ? I was able to purchase a large container that had 10,000 .12 grams pellets for 15.00 from walmart so it was cheap. I threw two on just to make myself feel better....

I used my electric reloading scales and converted to grains. 10 ounces is something like 4375 grains or ? I was able to purchase a large container that had 10,000 .12 grams pellets for 15.00 from walmart so it was cheap. I threw two on just to make myself feel better....

is leaning towards the redline and I may be also even though Metal tech is fairly local to me and I could drive there in 3 hours! However I am hunting Colorado this year and may be able to swing by redline just as easily....

is leaning towards the redline and I may be also even though Metal tech is fairly local to me and I could drive there in 3 hours! However I am hunting Colorado this year and may be able to swing by redline just as easily....

looks awesome

looks awesome

Also I wish I would have cut a bit less out of it in order for it to have lined up perfectly rather than a 1/4" low....

Also I wish I would have cut a bit less out of it in order for it to have lined up perfectly rather than a 1/4" low....