euclid

SILVER Star

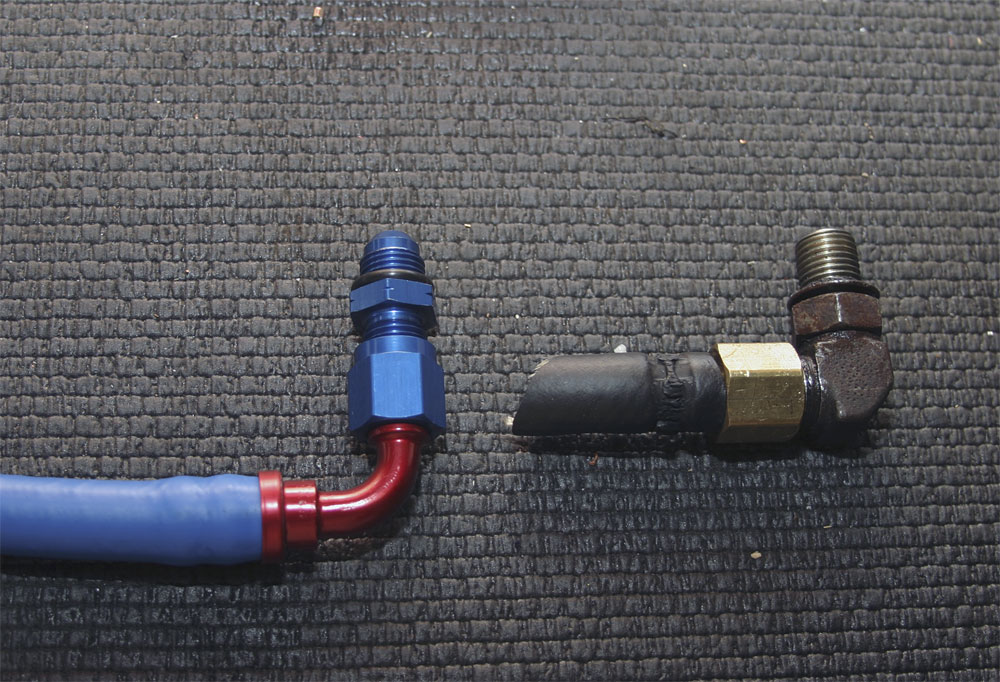

Removed the cooler outlet hose, then cut the crimp colar off of both ends and removed the stock barb fittings from the cooler hose from underneath the crimp colar.

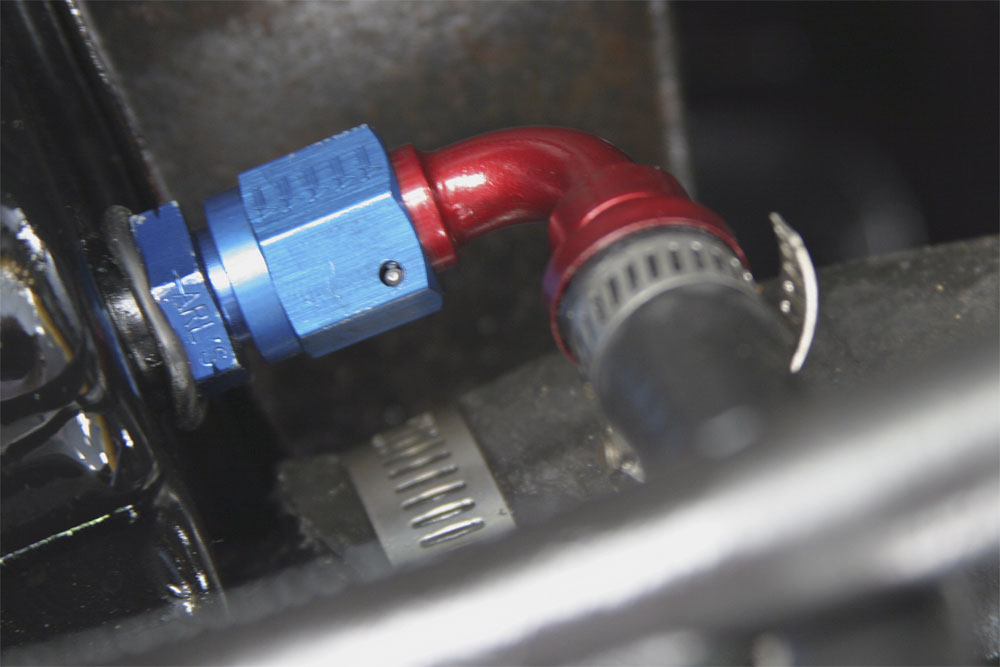

Install 3/8 transmission cooler line from the parts store onto the barbed fittings that came out of the cooler line.

One of the barbed fittings goes back onto the radiator, then route it to the cooler in front of the radiator. Then, come out of the other side of the cooler with another section of 3/8 hose and route it to where the old factory cooler line connected into the factory hard line where you use the other barbed fitting to send fluid back into the radiator. This conncetion is at the hard line where the first section of the old factory cooler hose (flexible) meets the second section of stock hose (ridged). You are using the barbed fittings out of each end of the factory cooler line and removeing it.

To mount the cooler I made a bracket and installed it using the factory bolts that hold the hood latch on. The pictures show the bracket. I plan on removing it and trimming it down and painting it to make it look more stock. I had to move the ridged cooler line that runs in front of the radiator forward a little bit to keep it from rubbing.

See pictures for a better understanding.

GT

++++++++++++++++++++

Some questions from KLF, and my answers:

Hey Greg:

Thanks for the pics, now I'm convinced I need to do this on mine.How did you cut that crimped collar? With a hacksaw or cutoff tool? Something that would be really helpful in your write-up would be to includethe manuf & part number of the cooler that you used, where you got it,price, etc. Was it a complete kit? Or just the cooler? Did you have to buy additional hose? If so, how much (length)? I assume you mean the hose is 3/8" ID, correct?

-KLF

+++++++++++++++++

My answers:

I used my angle grinder with a cut off wheel to slice the crimp, then pryed it open, and the barbed fitting slid right out. A dremmel would have been easier to work with.

I used the the B&M cooler #70268 from Summit Racing which got a thumbs up from Rodney. If I were going to do it again I would find a cooler that uses threaded conections on the bottom of the cooler rather than a barbed fitting with a hose clamp. This would make a cleaner install which is important to me considering it is slightly visible from the front of the truck. Don't know who makes one.

I used about 10 total feet of 3/8 ID hose. I bought hose from the parts store that says "transmission cooler" on it. Didn't use any of the 4" of hose that came with my kit. I am going to throw it in my truck for spare.

GT

Install 3/8 transmission cooler line from the parts store onto the barbed fittings that came out of the cooler line.

One of the barbed fittings goes back onto the radiator, then route it to the cooler in front of the radiator. Then, come out of the other side of the cooler with another section of 3/8 hose and route it to where the old factory cooler line connected into the factory hard line where you use the other barbed fitting to send fluid back into the radiator. This conncetion is at the hard line where the first section of the old factory cooler hose (flexible) meets the second section of stock hose (ridged). You are using the barbed fittings out of each end of the factory cooler line and removeing it.

To mount the cooler I made a bracket and installed it using the factory bolts that hold the hood latch on. The pictures show the bracket. I plan on removing it and trimming it down and painting it to make it look more stock. I had to move the ridged cooler line that runs in front of the radiator forward a little bit to keep it from rubbing.

See pictures for a better understanding.

GT

++++++++++++++++++++

Some questions from KLF, and my answers:

Hey Greg:

Thanks for the pics, now I'm convinced I need to do this on mine.How did you cut that crimped collar? With a hacksaw or cutoff tool? Something that would be really helpful in your write-up would be to includethe manuf & part number of the cooler that you used, where you got it,price, etc. Was it a complete kit? Or just the cooler? Did you have to buy additional hose? If so, how much (length)? I assume you mean the hose is 3/8" ID, correct?

-KLF

+++++++++++++++++

My answers:

I used my angle grinder with a cut off wheel to slice the crimp, then pryed it open, and the barbed fitting slid right out. A dremmel would have been easier to work with.

I used the the B&M cooler #70268 from Summit Racing which got a thumbs up from Rodney. If I were going to do it again I would find a cooler that uses threaded conections on the bottom of the cooler rather than a barbed fitting with a hose clamp. This would make a cleaner install which is important to me considering it is slightly visible from the front of the truck. Don't know who makes one.

I used about 10 total feet of 3/8 ID hose. I bought hose from the parts store that says "transmission cooler" on it. Didn't use any of the 4" of hose that came with my kit. I am going to throw it in my truck for spare.

GT