Distributor is 1/2 tooth off!

So, rotated the distributor by 1 tooth. FSM says rotor should point just before the left screw hole. Put it in with rotor pointing a bit to the right of screw hole (1 tooth over). Previously, it pointed a bit to the left of screw hole (more to the left than FSM).

Now I could rotate the distributor farther without hitting the head. I timed it (actually saw the dots like you're supposed to). Couldn't time it (see the dots) previously with distributor on other tooth.

Hint #1 Don't worry too much about oil pump position: The distributor didn't go down all the way. It was in the cam gear, but not in the oil slot. Bumped the motor with a little pressure on the distributor and it dropped in.

Hint #2 Use a mirror for timing: Essential! I would get a line on the timing window, but when I turned the distributor, a plug wire would get in my line of sight. I put a mirror close to the timing window so this wouldn't happen anymore.

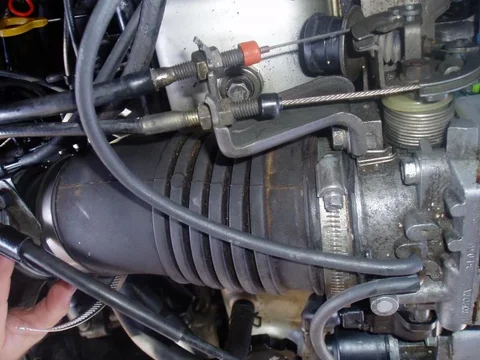

Okay, I said 1/2 tooth off. See pic

Notice bolt is out and there is no way for it to be installed. I'm not sure how a distributor get's 1/2 tooth off, but it is.

How 1/2 tooth off? It's gotta be the gears. Gear on distributor are "turned" a bit (hope so). This must be rare (lucky me) because the gear is held in with a pin. Gear on camshaft is off. This would be BAD! This would mean even if I buy a brand new one for $700, it still won't go in there right.

Hillbilly Solution: If the $100 used distributor I am going to purchase leaves me where I am right now, I'm going to cut the adjustment so the screw can go in and still hold down the distributor.

So, let's hope that it's the distributor!

Code 12: It is throwing a code 12 which means the gaps in the distributor are not right. I hope the gaps on the used distributor fixes this. I'm messed with the gaps quite a bit and DON'T want to have to screw with that again.

And the saga continues. . . . .