2001LC

SILVER Star

The reason we do not like metal screws holding molding in. The metal screws, break thought factory paint in/at side of holes, and cause rust in "A" pillar.

Toyota does have various size aluminum plastic coated rivets. Just visit the parts counter and ask what they can find. I've found 90269-04053 stock 100 series, also an over-sized 90269-05034. They may have others. Also many installer, have many various sizes they carry.

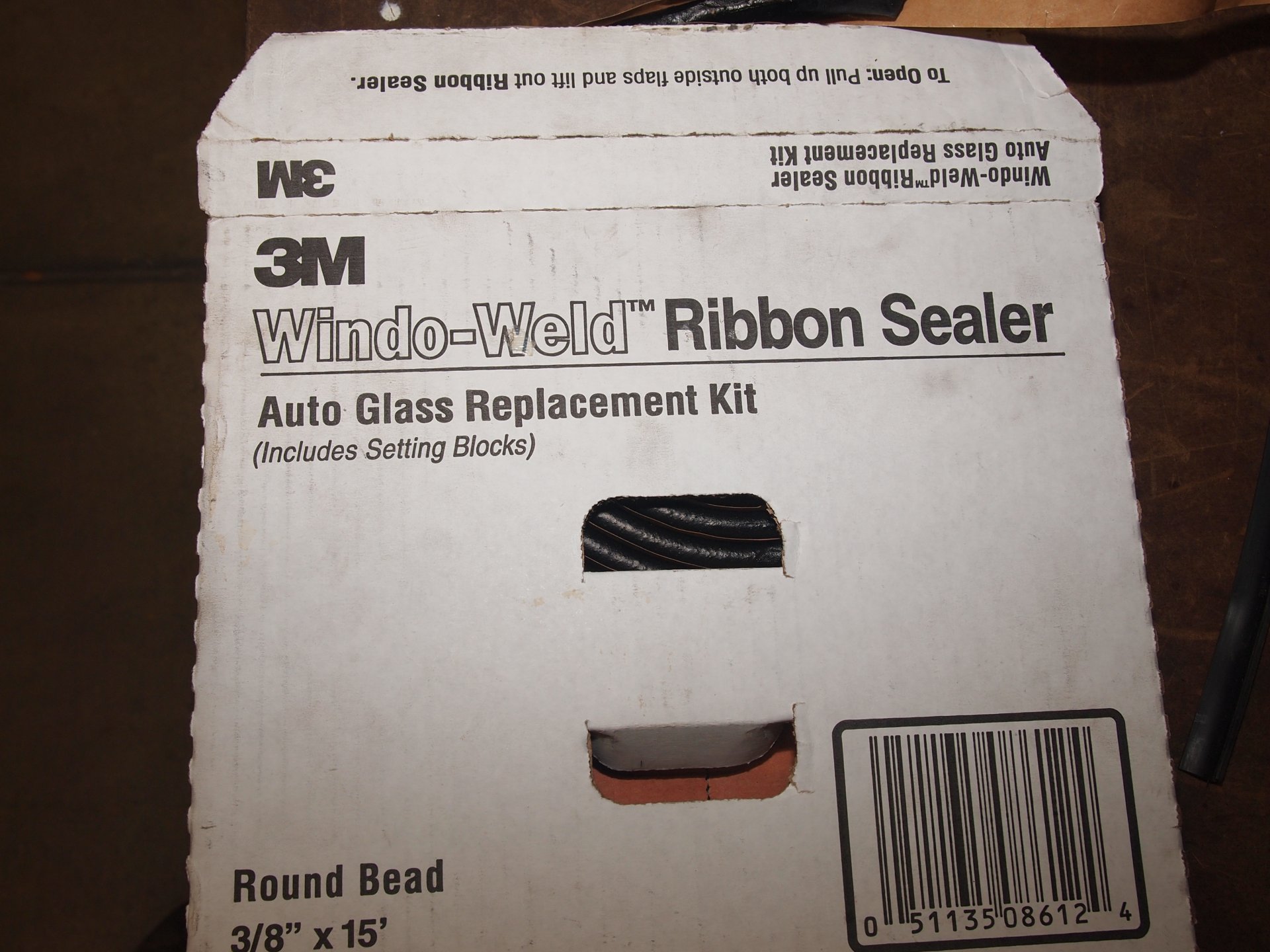

If I see any issue with molding, I remove it. I plug open holes with butyl, even leaks in the black poly (temp repair). Parts stores carry 3M windshield sealant tape. Which if you look closely on package, is butyl.

During final repair, which usually means glass replacement. I first correct paint issues, which may include de-rusting and painting. If it's just a case of paint cut away from any of the 8 rivet holes and/or holes slightly enlarged. I paint holes with POR-15. I coat hole up to 5 or 6 times, checking size after each coat with a rivet. Any extra (not factor) holes drilled in "A" pillar, I plug with windshield butyl, before installing molding.

I make sure no black poly is between "A" pillar and glass. This is a rian/water channel, where water drains on and under molding. So we do not want any blockage under molding.

The butyl can be used as temp or long term leak plug. Under the molding out of the sun, will last a life time. I've had butyl in open holes, without side molding, For over 2 years and counting.

To check for leaks I turn AC to max, outside air and place blower in window. I use soapy water or windshield glass clean, applying all around glass. Then watch for air bubbles in the suds.

This hole are not only rusty and enlarged. But the installer must have pounded in screws, bending the metal of "a" pillar at holes. What a mess, I be dealing with as need. But for now so it can be outside, washed and tested for leaks. I fill holes with butyl.

Blower with hose into window and sealed with sun shade. Which was best I could do fast and easily without tape, with stuff lying around. Not a 100 % seal, but good enough for this test with cabin fresh air open and HVAC blower on max.

Leak was found between glass and black poly at upper LH comer. Plugged with butyl temporarily. Than tested again for air bubbles after temp repair. No bubbles after repair, so no leaks.

Here you can see all "A" pillars molding holes plugged with butyl. I've had it this way and keep outdoors for over 2 years. Butyl is still pliable.

Toyota does have various size aluminum plastic coated rivets. Just visit the parts counter and ask what they can find. I've found 90269-04053 stock 100 series, also an over-sized 90269-05034. They may have others. Also many installer, have many various sizes they carry.

If I see any issue with molding, I remove it. I plug open holes with butyl, even leaks in the black poly (temp repair). Parts stores carry 3M windshield sealant tape. Which if you look closely on package, is butyl.

During final repair, which usually means glass replacement. I first correct paint issues, which may include de-rusting and painting. If it's just a case of paint cut away from any of the 8 rivet holes and/or holes slightly enlarged. I paint holes with POR-15. I coat hole up to 5 or 6 times, checking size after each coat with a rivet. Any extra (not factor) holes drilled in "A" pillar, I plug with windshield butyl, before installing molding.

I make sure no black poly is between "A" pillar and glass. This is a rian/water channel, where water drains on and under molding. So we do not want any blockage under molding.

The butyl can be used as temp or long term leak plug. Under the molding out of the sun, will last a life time. I've had butyl in open holes, without side molding, For over 2 years and counting.

To check for leaks I turn AC to max, outside air and place blower in window. I use soapy water or windshield glass clean, applying all around glass. Then watch for air bubbles in the suds.

This hole are not only rusty and enlarged. But the installer must have pounded in screws, bending the metal of "a" pillar at holes. What a mess, I be dealing with as need. But for now so it can be outside, washed and tested for leaks. I fill holes with butyl.

Blower with hose into window and sealed with sun shade. Which was best I could do fast and easily without tape, with stuff lying around. Not a 100 % seal, but good enough for this test with cabin fresh air open and HVAC blower on max.

Leak was found between glass and black poly at upper LH comer. Plugged with butyl temporarily. Than tested again for air bubbles after temp repair. No bubbles after repair, so no leaks.

Here you can see all "A" pillars molding holes plugged with butyl. I've had it this way and keep outdoors for over 2 years. Butyl is still pliable.