- Thread starter

- #21

This project was put on hold for a while, after I received the axles from the UK.

A couple of weeks after the crate arrived, I found some time to open it up and have a look at my new Volvo portal axles.

I was devastated to find that they did not have the right hand rear diff centre offset, from a 4x4 Volvo C303, that I had been promised, but that they were the more centred rear diff centre housing from a rear axle on a 6x6 Volvo C304/C306.

I contacted the seller, and the f**kwit refused to accept that he had sent the incorrect axles, kept saying that he knows more about these axles than I do, that I am never happy, and that he had sent exactly what he had originally agreed to. He eventually just started to ignore my demands that he do something to remedy the situation at his cost.

I then also worked out that not only were they not the right hand rear diff centre offset, but as I suspected from the incorrect rear offset, that they were also not the 5.99:1 ratio diffs that I had been promised as well, and were actually 7.10:1 ratio front/rear diffs.

After spending so much for the axles, and so much in freight, import taxes and duties, etc. to get them here, about $9000 all up, I had recevied axles that were not what he promised I was buying, that I didn't want, that I couldn't really use for my conversion...it was very depressing.

Thankfully, the guy that runs the 4WD team that the seller is (was?) a part of, decided to take it upon himself to remedy the situation, when he really didn't have to, as it was sort of indirectly related to his team. He called in some favours from people he knows in Europe, and has got together a replacement rear axle housing, with the correct right hand diff centre offset, a pair of matching rear axle half shafts, and a pair of front/rear crownwheels and pinions in the correct 5.99:1 ratios.

So, I will have to pay to have these replacement parts shipped out from the UK to Australia, as the original seller refuses to accept any responsibility for his possibly intentional, or less likely accidental, f**kup. But at least I will have what I originally thought I was buying, and what I need for the conversion to work.

I am now waiting to get the replacement parts shipped from the UK, so hopefully in a couple of months I should be back on track with the correct axles that I should have received back in August last year. And it will be over a year after I paid for them back in February last year. I f**king hate the seller, I hope he dies a slow and painful death.

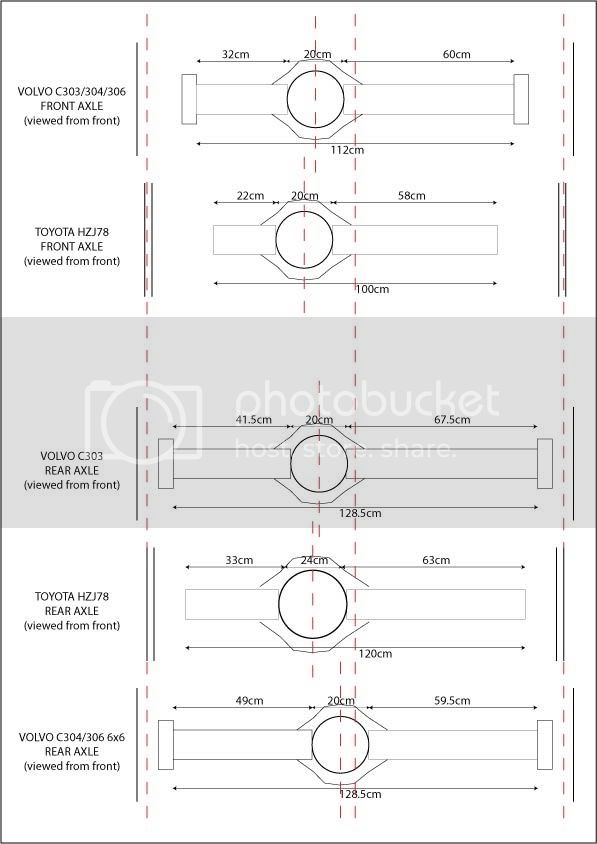

These are the incorrect axles that I received...

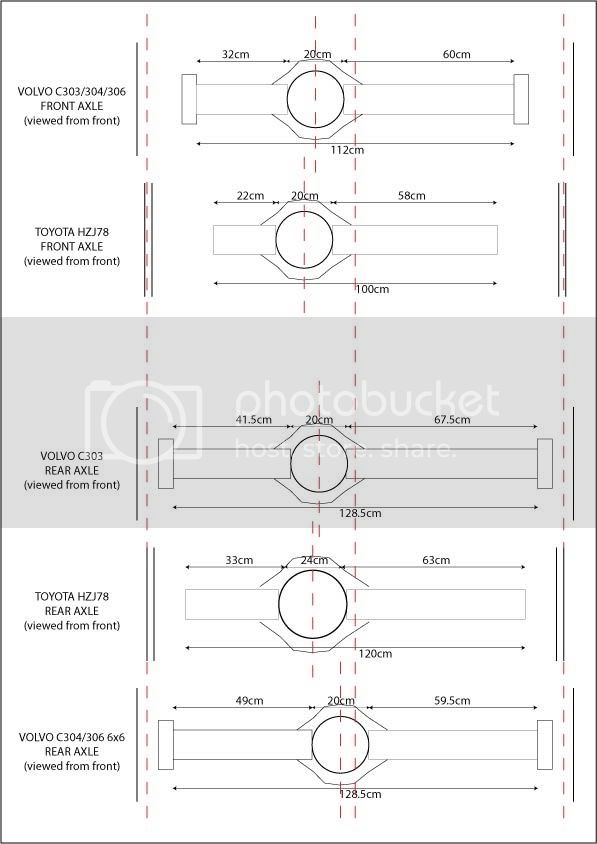

This shows the approximate difference in diff offsets of the 4x4 and 6x6 Volvo axles compared to my standard HZJ78 axles. The red lines are the centre line of the axles, the centreline of the diff centres, and the outer red lines show the maximum track width I can go to at 50mm over standard (hopefully with recent updates to the rego rules, this 50mm maximum increase will no longer apply, and I can use the standard Volvo axle track width). The outer black lines are the track width, plus the second black line on the HZJ78 axles show the track width plus 50mm maximum increase...

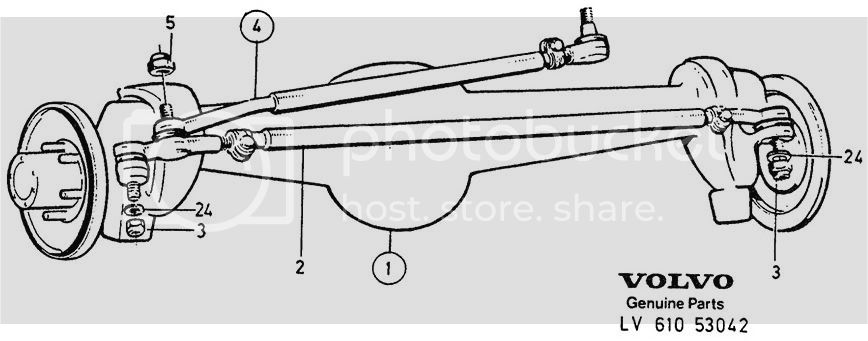

This is the offset of the incorrect rear axle, showing approx 19 inches from the right hand side portal box flange to the edge of the diff centre cover...

This is the offset of the replacement/correct rear axle, showing approx 14 inches from the right hand side portal box flange to the edge of the diff centre cover, hopefully he is debracketting and cleaning these up for me before he sends them...

This is the diff ratio plate on the incorrect axles, showing the incorrect 9X31 ratio (= 3.444444 x 2.06 reduction in the portal boxes = 7.095555:1), that the seller carefully painted around when refurbishing the axles, so he should have (or did) know they were not the correct ratio...

This is the diff ratio plate on the replacement/correct axles, showing the correct 11x32 ratio (= 2.90909 x 2.06 reduction in the portal boxes = 5.992727:1), that I should have originally received...

A couple of weeks after the crate arrived, I found some time to open it up and have a look at my new Volvo portal axles.

I was devastated to find that they did not have the right hand rear diff centre offset, from a 4x4 Volvo C303, that I had been promised, but that they were the more centred rear diff centre housing from a rear axle on a 6x6 Volvo C304/C306.

I contacted the seller, and the f**kwit refused to accept that he had sent the incorrect axles, kept saying that he knows more about these axles than I do, that I am never happy, and that he had sent exactly what he had originally agreed to. He eventually just started to ignore my demands that he do something to remedy the situation at his cost.

I then also worked out that not only were they not the right hand rear diff centre offset, but as I suspected from the incorrect rear offset, that they were also not the 5.99:1 ratio diffs that I had been promised as well, and were actually 7.10:1 ratio front/rear diffs.

After spending so much for the axles, and so much in freight, import taxes and duties, etc. to get them here, about $9000 all up, I had recevied axles that were not what he promised I was buying, that I didn't want, that I couldn't really use for my conversion...it was very depressing.

Thankfully, the guy that runs the 4WD team that the seller is (was?) a part of, decided to take it upon himself to remedy the situation, when he really didn't have to, as it was sort of indirectly related to his team. He called in some favours from people he knows in Europe, and has got together a replacement rear axle housing, with the correct right hand diff centre offset, a pair of matching rear axle half shafts, and a pair of front/rear crownwheels and pinions in the correct 5.99:1 ratios.

So, I will have to pay to have these replacement parts shipped out from the UK to Australia, as the original seller refuses to accept any responsibility for his possibly intentional, or less likely accidental, f**kup. But at least I will have what I originally thought I was buying, and what I need for the conversion to work.

I am now waiting to get the replacement parts shipped from the UK, so hopefully in a couple of months I should be back on track with the correct axles that I should have received back in August last year. And it will be over a year after I paid for them back in February last year. I f**king hate the seller, I hope he dies a slow and painful death.

These are the incorrect axles that I received...

This shows the approximate difference in diff offsets of the 4x4 and 6x6 Volvo axles compared to my standard HZJ78 axles. The red lines are the centre line of the axles, the centreline of the diff centres, and the outer red lines show the maximum track width I can go to at 50mm over standard (hopefully with recent updates to the rego rules, this 50mm maximum increase will no longer apply, and I can use the standard Volvo axle track width). The outer black lines are the track width, plus the second black line on the HZJ78 axles show the track width plus 50mm maximum increase...

This is the offset of the incorrect rear axle, showing approx 19 inches from the right hand side portal box flange to the edge of the diff centre cover...

This is the offset of the replacement/correct rear axle, showing approx 14 inches from the right hand side portal box flange to the edge of the diff centre cover, hopefully he is debracketting and cleaning these up for me before he sends them...

This is the diff ratio plate on the incorrect axles, showing the incorrect 9X31 ratio (= 3.444444 x 2.06 reduction in the portal boxes = 7.095555:1), that the seller carefully painted around when refurbishing the axles, so he should have (or did) know they were not the correct ratio...

This is the diff ratio plate on the replacement/correct axles, showing the correct 11x32 ratio (= 2.90909 x 2.06 reduction in the portal boxes = 5.992727:1), that I should have originally received...

Last edited:

, once you get them puppies stuck you are going to be ... upset.

, once you get them puppies stuck you are going to be ... upset.