Waggoner5

SILVER Star

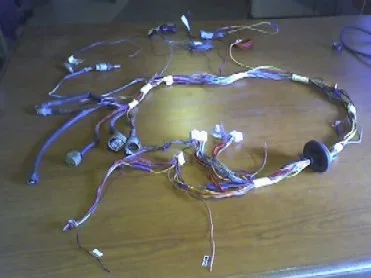

Kirk, I ran the Camaro/Firebird accessories which run on the PS side and it worked out great. The Power sterring hoses were longer having to run over to the other side but it made the alternator and AC really easy. I used all factory gauges and had the tach done to read the 8 cyl signal. If you need anything holler.

Gary

Gary