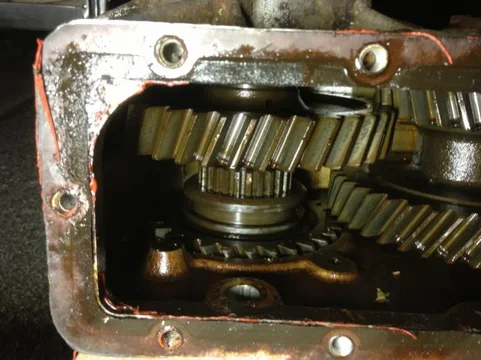

You might want to check that , ........ 2nd page, G22 thrust washers:

different than stock measurements. The shaft and gears should be set at .008"-.012" of end play. We now include two new thrust washers to help set up the transfer case with the correct end play. These thrust washer are stepped. One side has a recess of .015" - .017" and the other side of the washer has a .008" - .010" recess. So by using one side or the other of the washer or using your stock washers, you should be able to get close to the required tolerance. P/N O60080 (2 required) If you should have any further questions please call us @ 1-800-350-2223.

That has been in the Orion manual as long as I can remember them having the stepped washers in the kit. And that's been a few years now.

Georg @ Valley Hybrids