- Thread starter

- #301

I think it's fixed

Got a remanufactured pump at Autozone (Part 7011).

Was a quick easy install and It looks like I am all good.

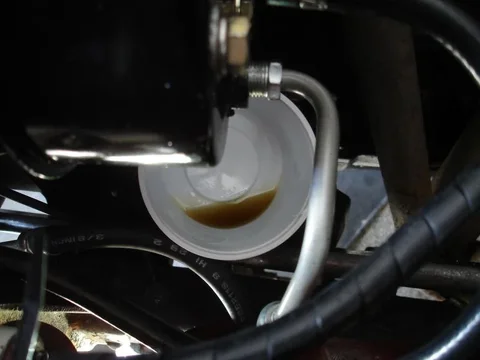

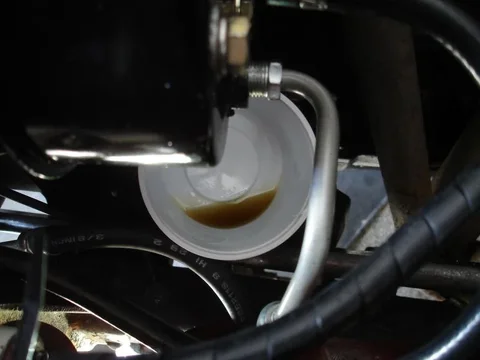

It has been cold here so nothing is too viscous right now but below you can see a weeks worth of static leaking.

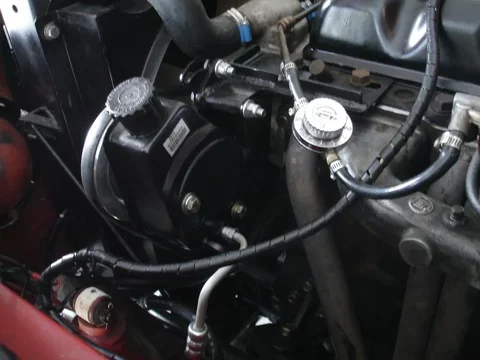

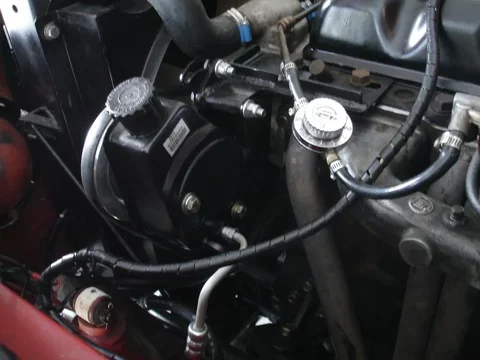

And the new pump.

I also replaced the temp sender with the correct one. I need to call Kurt and let him know that I think his catalog is wrong. He sent me another short one and those will not work in the early model trucks. Not sure why. I got fed up and bought the right one from CCOT.

Got a remanufactured pump at Autozone (Part 7011).

Was a quick easy install and It looks like I am all good.

It has been cold here so nothing is too viscous right now but below you can see a weeks worth of static leaking.

And the new pump.

I also replaced the temp sender with the correct one. I need to call Kurt and let him know that I think his catalog is wrong. He sent me another short one and those will not work in the early model trucks. Not sure why. I got fed up and bought the right one from CCOT.