This is for the electrically-inclined among you or for those who have done this upgrade:

So I'm in the process of upgrading my 62's quad sealed beams to a H1/H4 setup, using the wiring diagram here. I am using Hella housings and lamps with stock equivalent wattage. Before connecting the new harness I built, I plugged the new lamps into the existing wiring harness. I did this on the driver's side only - I was curious about the new lamps' output compared to the sealed beams, which I left in place on the passenger side. Installing one side only lets me compare the two.

Everything works, but I noticed 3 odd things:

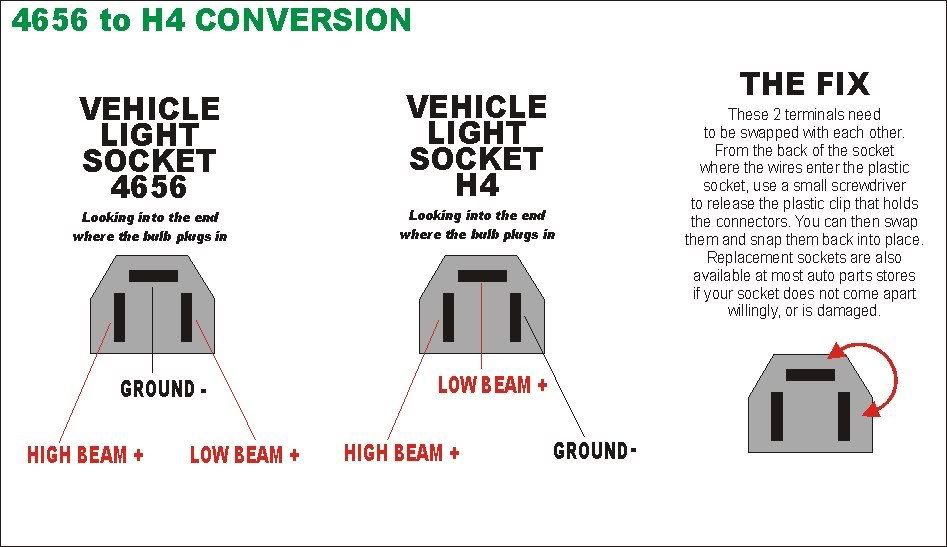

1) when activating the high beams, the new H4 low beam lamp dimmed to about 75%, while the existing sealed low beam stayed constant. The H4 goes back to 100% when the high beam is off.

2) with only the low beams activated, the high beam lamps glow faintly, both the new H1 high beam lamp and the existing sealed beam high beam lamp.

3) there is not much discernible light output difference between the two sides.

Again, this is using the existing wiring. Plug and play. I'll move ahead with the new harness shortly, which may bring its own surprise (and hopefully an improvement in light output), but I'm trying to troubleshoot this first step.

So I'm in the process of upgrading my 62's quad sealed beams to a H1/H4 setup, using the wiring diagram here. I am using Hella housings and lamps with stock equivalent wattage. Before connecting the new harness I built, I plugged the new lamps into the existing wiring harness. I did this on the driver's side only - I was curious about the new lamps' output compared to the sealed beams, which I left in place on the passenger side. Installing one side only lets me compare the two.

Everything works, but I noticed 3 odd things:

1) when activating the high beams, the new H4 low beam lamp dimmed to about 75%, while the existing sealed low beam stayed constant. The H4 goes back to 100% when the high beam is off.

2) with only the low beams activated, the high beam lamps glow faintly, both the new H1 high beam lamp and the existing sealed beam high beam lamp.

3) there is not much discernible light output difference between the two sides.

Again, this is using the existing wiring. Plug and play. I'll move ahead with the new harness shortly, which may bring its own surprise (and hopefully an improvement in light output), but I'm trying to troubleshoot this first step.