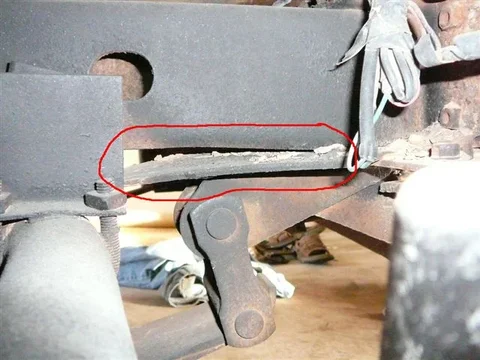

This is my stock (besides the nasty bumpers) '65 40. I am begining to do some work to this beast, more less a nice refresh, not a full restoration. There is very very little rust on the rig, but there is a little in the usual places. Mainly the rear. What I'm looking for is advice on how I should go about the body work. I will probably repalce the rear sill, but that still leaves the corners. As you can see, they're really not that bad but I want it to look nice. Has anyone worked with fiberglass for filling? What else do you guys recommend?