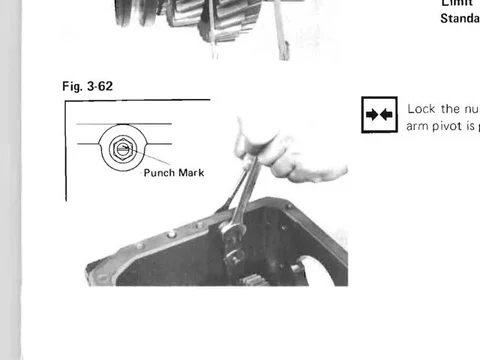

Step 19 - Counter shaft bearings

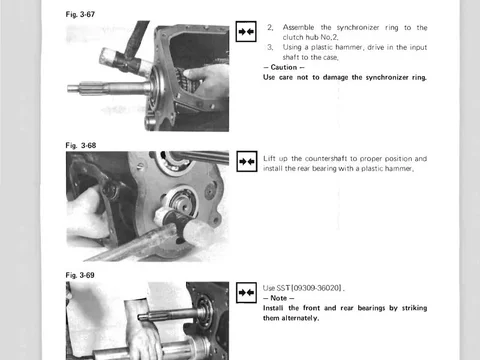

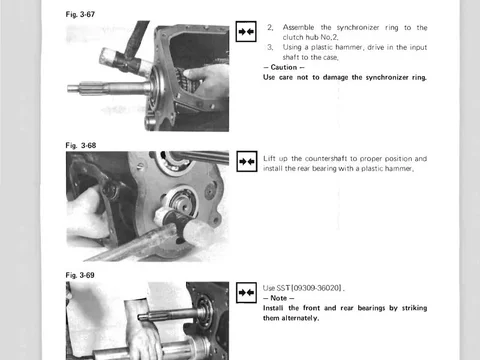

Start on the output side. Lift the counter shaft thru the square hole in the side of the case if you have one (I did not, what a pain). Start the bearing carefully with a plastic hammer.

Counter shaft bearing Output side

Hmm, easy peasy, right?

Right.

Tapped that sucker right in

Start the Input side bearing. FSM says you'll need to tap the two bearings in an alternating fashion.

See, look here, just a simple single photo and one line of text.

FSM is evil

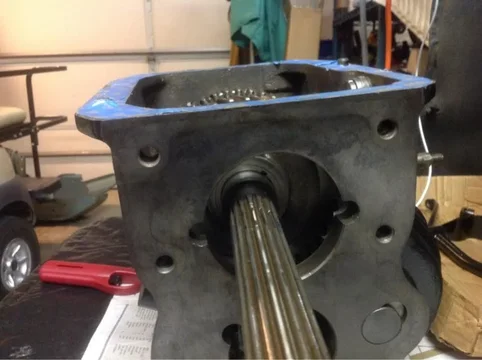

After tapping the two bearings back and forth for about an hour, moving from soft hammer to big brass drift and 3lb sledge, I couldn't get the bearings closer than 7 mm. One side would go flush, then the other side would stick out 7mm. Damnit!

7 lousy mm

I finally had the idea to attach the bearing retainer with long bolts, and put the old bearing over the new bearing on the output side to hold it so I could tap the other side into place.

Bearing retainer output side

This is where I effed up. Big time. I noticed that the bearing on the input side was just bouncing back now when I hit it. Before, it would move easily. Also, I noticed the main and counter shaft would not turn all the way around without hitting a snag. Hmmm, what's going on?

Lesson: don't just hit it harder. As I did this, a 1/4" long piece of hardened steel fell out of an opening in the side of the case. Oh, $h*t. I cursed for a couple of minutes, realizing I was so close to being done with this bastard, and now knowing I'd at least have to remove the lower bearings, and at most have to replace the counter shaft if I've broken teeth somehow.

I cleared off the cart, turned the tranny on the side, and.... Nothing. Hmmm. Then I turned it upside down and ... Tinkle, tinkle, tinkle. The horrible sound of bits, nay, chunks of metal falling out. Oh man.

I turned the case back and found about 15 pieces of metal chunks. Ok, off with the bearings.

A tranny's worst nightmare

So once I got the lower bearings back off, I immediately saw the problem: between the inner race of the bearing on the output side, and the small gear on the countershaft, I shattered the ridge of material by putting too much pressure on the race somehow. I needed to only move the outer race but when I braced the bearing in the retainer, the shaft must have put pressure where it should not have.

Either that or I assembled something incorrectly.

Shattered lip

This is what broke

Lip that broke

Question is - now what?