Figured I would start a thread keeping track of all the work I end up doing bringing this truck up to where I want it.

I got the truck back in November and planned to have a solid running rig with some of the things I would have done that I can commute to work in this winter then take out to the trails in the summer and fall. When I received the truck I figured out exactly how to start the thing then immediately loaded it up with my coworkers and took it out to see how it ran. The truck ran super strong so I commuted home and back the next day and noticed the was major wiring and oil leak problems I would address soon.

Coming off the shipping truck at work

Firstly I had to address the wiring. The weather was still nice so I kept riding my motorcycle to work and pulled the truck in the shop and tried to make sense of it all. Anyone could start the car as there was simply a button pulling power right from the batter to the starter and the key did nothing but unlock the steering wheel. Horrible idea in Chicago when paired with a mediocre locking system. After that I would address the issue with the gauges working intermittently or not at all.

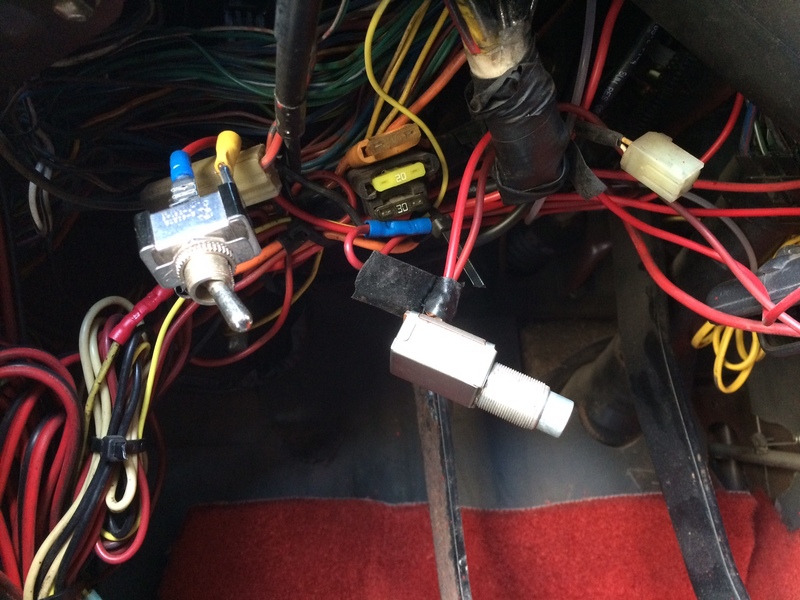

This was the just half the situation under the steering wheel. Lots of electrical tape, switches, and fuses.

Here was the other half. Switch for the headlights and you can see the box for the tach on the floor in the background.

Here was the engine bay as I uncovered everything and began trying to make sense of it. Tracing wires from the cabin to the bay alone was a complete pain in the ass. It took hours since every wire was red besides the 3 for the headlights (all yellow) and the routing was nonsensical.

Here is a case of wiring where it took more effort to make it wrong. Wires around other wires.

More wiring double dutch

As you can see, I more than had my work cut out for me. After over 10 hours alone of messing with this I had a buddy I build cars with help me out to simply let me know what wire was moving in the bay when I pulled in the cabin. He was nice enough to stay and help me run a meter and further check everything out. We found quite a few wires that were loose on one end and also some that were zip tied into the mix and were connected to anything on either end. Once I got extraneous stuff out of the way and had help I was able to really fly through the wiring, or so I thought. We got to a point where everything worked besides the passenger side markers. We knew what color they were supposed to be so he ran the meter in the bay and I checked the passenger kick panel area.

Here is where I almost gave up on the project;

Uh oh, this don't look good. I assumed the rest of the harness would have been fine since all the previous splices/problems were on the drivers side and under the dash. You know what they say when you assume things...

Once I unwrapped that I got a good idea of just how screwed I was. Every wire was cut and spliced and there was a clear meltdown with the headlight wires previously.

This was, BY FAR, the worst wiring I had ever seen. I was actually almost completely over it but I wasn't going to let a simple diesel swap and some rats nest wiring beat me. Lets fast forward an hour (after I put the hammer down and stepped away from the truck a while) Wipers are also stuck up because they didn't work and I was trying to figure those out as well when I took mental brakes from the wiring.

A spare harness came with the truck so I went through that one with a fine tooth comb, found a few more issues, but was able to iron those out before I put it back in the car. Solder and heat shrink, no tape.

While I was fitting the entire harness it was time to get this to run off the OEM key. I always thought it was odd the key was so smooth when unlocking the wheel so I took the column cover off and found that the ignition switch was just floating around in there. Well, time to figure out what the heck fastener it takes to fix this. The drill/tap/thread guide made this easy once I found the major diameter

I then also noticed that there were more loose/cut and generally hacked at wires there. That made me glad I removed that cover, no point of leaving any stones unturned now. The top is how I remedy these problems. The bottom is how I found these.

By this time I was making short work of all this. The harness was a million times easier to see and repair outside of the truck so once I had the replacement all buttoned up I gladly removed not only the one in the truck but almost every single wire dash/firewall forward. It was time to do it all the correct way. That meant an OEM harness, running from a OEM key, switching back to OEM gauges, and some type of headlight harness. Here we have how it looked after reinstalling everything.

Drivers side

Passenger side

Engine bay, not complete. Still messy and missing a few gauges to run the OEM dash properly.

I got the truck back in November and planned to have a solid running rig with some of the things I would have done that I can commute to work in this winter then take out to the trails in the summer and fall. When I received the truck I figured out exactly how to start the thing then immediately loaded it up with my coworkers and took it out to see how it ran. The truck ran super strong so I commuted home and back the next day and noticed the was major wiring and oil leak problems I would address soon.

Coming off the shipping truck at work

Firstly I had to address the wiring. The weather was still nice so I kept riding my motorcycle to work and pulled the truck in the shop and tried to make sense of it all. Anyone could start the car as there was simply a button pulling power right from the batter to the starter and the key did nothing but unlock the steering wheel. Horrible idea in Chicago when paired with a mediocre locking system. After that I would address the issue with the gauges working intermittently or not at all.

This was the just half the situation under the steering wheel. Lots of electrical tape, switches, and fuses.

Here was the other half. Switch for the headlights and you can see the box for the tach on the floor in the background.

Here was the engine bay as I uncovered everything and began trying to make sense of it. Tracing wires from the cabin to the bay alone was a complete pain in the ass. It took hours since every wire was red besides the 3 for the headlights (all yellow) and the routing was nonsensical.

Here is a case of wiring where it took more effort to make it wrong. Wires around other wires.

More wiring double dutch

As you can see, I more than had my work cut out for me. After over 10 hours alone of messing with this I had a buddy I build cars with help me out to simply let me know what wire was moving in the bay when I pulled in the cabin. He was nice enough to stay and help me run a meter and further check everything out. We found quite a few wires that were loose on one end and also some that were zip tied into the mix and were connected to anything on either end. Once I got extraneous stuff out of the way and had help I was able to really fly through the wiring, or so I thought. We got to a point where everything worked besides the passenger side markers. We knew what color they were supposed to be so he ran the meter in the bay and I checked the passenger kick panel area.

Here is where I almost gave up on the project;

Uh oh, this don't look good. I assumed the rest of the harness would have been fine since all the previous splices/problems were on the drivers side and under the dash. You know what they say when you assume things...

Once I unwrapped that I got a good idea of just how screwed I was. Every wire was cut and spliced and there was a clear meltdown with the headlight wires previously.

This was, BY FAR, the worst wiring I had ever seen. I was actually almost completely over it but I wasn't going to let a simple diesel swap and some rats nest wiring beat me. Lets fast forward an hour (after I put the hammer down and stepped away from the truck a while) Wipers are also stuck up because they didn't work and I was trying to figure those out as well when I took mental brakes from the wiring.

A spare harness came with the truck so I went through that one with a fine tooth comb, found a few more issues, but was able to iron those out before I put it back in the car. Solder and heat shrink, no tape.

While I was fitting the entire harness it was time to get this to run off the OEM key. I always thought it was odd the key was so smooth when unlocking the wheel so I took the column cover off and found that the ignition switch was just floating around in there. Well, time to figure out what the heck fastener it takes to fix this. The drill/tap/thread guide made this easy once I found the major diameter

I then also noticed that there were more loose/cut and generally hacked at wires there. That made me glad I removed that cover, no point of leaving any stones unturned now. The top is how I remedy these problems. The bottom is how I found these.

By this time I was making short work of all this. The harness was a million times easier to see and repair outside of the truck so once I had the replacement all buttoned up I gladly removed not only the one in the truck but almost every single wire dash/firewall forward. It was time to do it all the correct way. That meant an OEM harness, running from a OEM key, switching back to OEM gauges, and some type of headlight harness. Here we have how it looked after reinstalling everything.

Drivers side

Passenger side

Engine bay, not complete. Still messy and missing a few gauges to run the OEM dash properly.