Ackcruisers

SILVER Star

I’m experiencing a slight grind when shifting into 3rd gear (it grinds then finds slot). Also occasional grind when down shifting into 2nd gear on my “rebuilt” 3-speed. This just started happening once I replaced the hydraulic system. Have my 2nd and 3rd syncros failed?

I replaced the master, slave, hardline, and softline. Adjusted pedal and slave per FSM specs. Bled entire system many times to confirm no air.

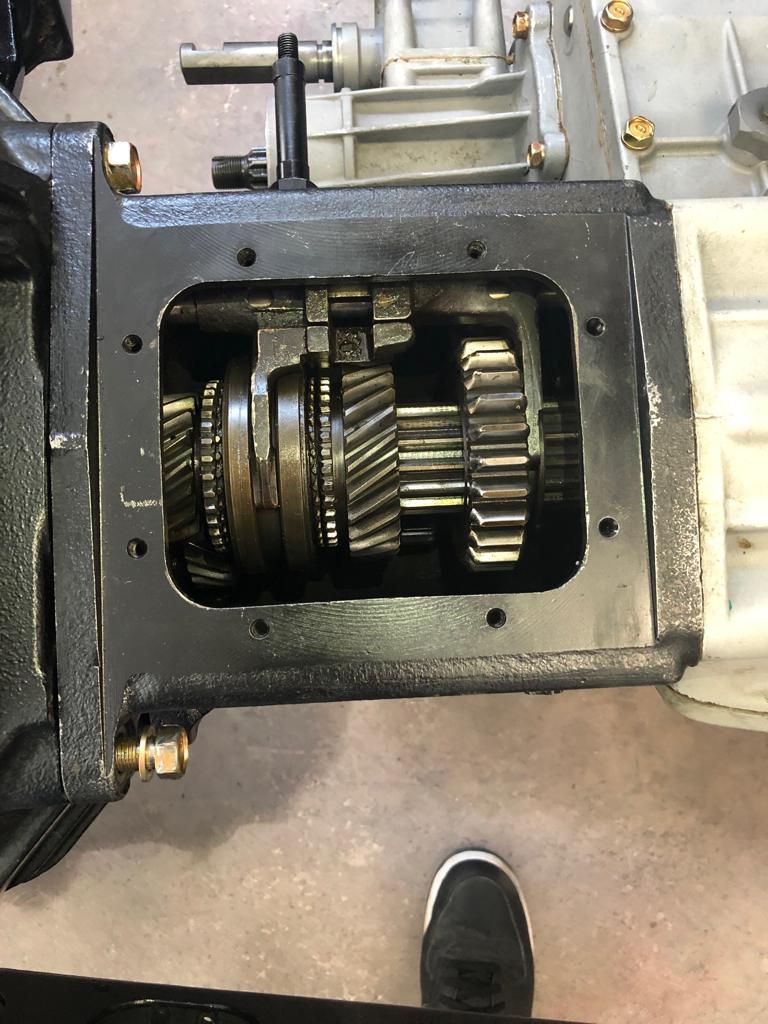

Here is picture of the transmission with cover off. Truck has 600 miles on it since “rebuild”.

I really like the 3 speed but it’s all I’ve ever know as j30 was in my 69 and 72 40’s. They both never grinded going into 3rd.

I’m also experiencing leaks at the front bearing retainer see below.

Also, experiencing some shudder in clutch once everything is warmed up.

Given the above and all unknowns combined with no confidence in the Colombian restoration of drive train, I’m considering having a specialist (Cruiser Solutions) in NH drop transmission, transfer and go through entire drive train.

I replaced the master, slave, hardline, and softline. Adjusted pedal and slave per FSM specs. Bled entire system many times to confirm no air.

Here is picture of the transmission with cover off. Truck has 600 miles on it since “rebuild”.

I really like the 3 speed but it’s all I’ve ever know as j30 was in my 69 and 72 40’s. They both never grinded going into 3rd.

I’m also experiencing leaks at the front bearing retainer see below.

Also, experiencing some shudder in clutch once everything is warmed up.

Given the above and all unknowns combined with no confidence in the Colombian restoration of drive train, I’m considering having a specialist (Cruiser Solutions) in NH drop transmission, transfer and go through entire drive train.