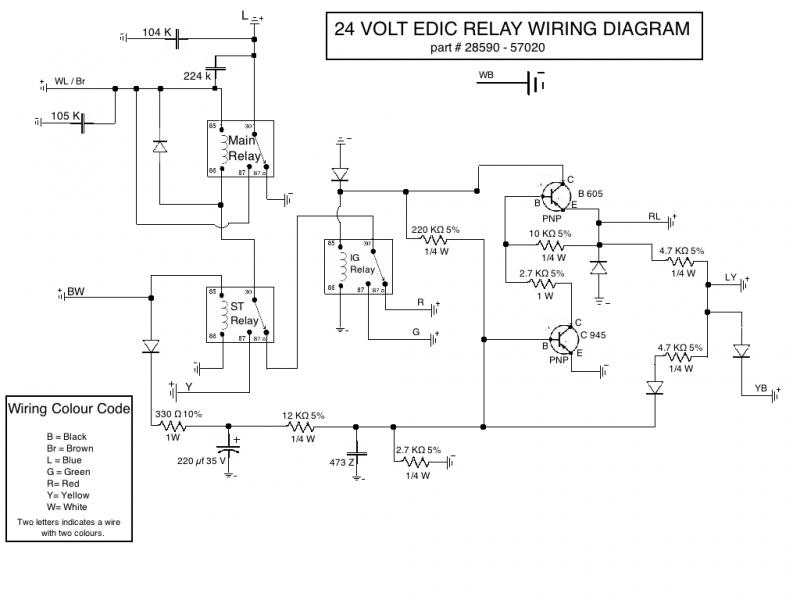

Lately I’ve been having issues with my EDIC on by 24 volt BJ42. Sometimes the engine wouldn’t stop, sometimes it wouldn’t start and other times I would get what is often called the funky chicken where the EDIC motor just keeps on running. After some research and lot’s of testing the conclusion is the EDIC motor is fine but the controller is pooched. It’s been filled with water and road salt more than once and it’s 30 years old so it’s time for a new one. All the problems described earlier were due to corrosion of the printed circuit board and bad contacts in the relays. It is possible to wire new relays but the printed board was so bad that new was the way to go. In all after the figuring out of the wiring diagram a couple of hours was all it took to build the box.

All the parts common enough to find in an electronic store, your local auto parts store and the easiest of all E-bay.

All the parts common enough to find in an electronic store, your local auto parts store and the easiest of all E-bay.

)

)