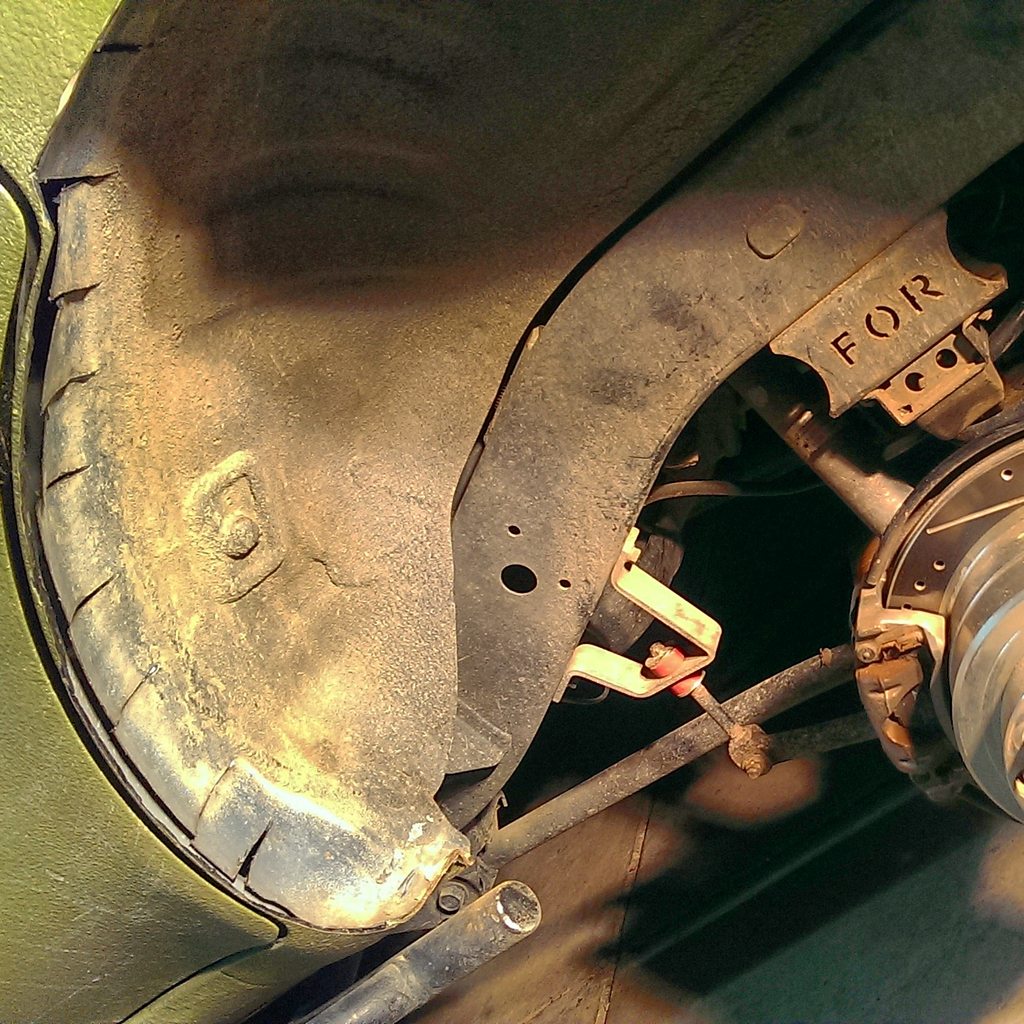

okay I've been searching the last past 2 nights about how to cut my front fenders and the real concern is not how to cut the actual fender but how to cut the inner front fender. What I've come up with was 2 ways:

1. Pizza slice them, bend and weld them to the cut outer fender

2. Just cut the inner fender completely off at the half way seam. (Leaning towards this option)

Which did you guys do?

I've researched and people are concerned about water/mud splashing to the fuse/junction area. But with both ways mud and water will splash because of the openings.

If you welded the inner fender to the outer, are you still able to remove the fender just in case it needs to be replaced?

If you cut the inner fender at the halfway seam, is the fender strong enough to dangle on its own without support?

I just installed 37's and I need to cut 2 inches off the fender, don't want to space down the travel.

Also, is 2 inches enough?

How much have you cut?

1. Pizza slice them, bend and weld them to the cut outer fender

2. Just cut the inner fender completely off at the half way seam. (Leaning towards this option)

Which did you guys do?

I've researched and people are concerned about water/mud splashing to the fuse/junction area. But with both ways mud and water will splash because of the openings.

If you welded the inner fender to the outer, are you still able to remove the fender just in case it needs to be replaced?

If you cut the inner fender at the halfway seam, is the fender strong enough to dangle on its own without support?

I just installed 37's and I need to cut 2 inches off the fender, don't want to space down the travel.

Also, is 2 inches enough?

How much have you cut?