Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Blender, My LX450/FZJ80 + FJ45esk + GM + Land Rover crazy concoction

- Thread starter Mieser

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?It is a standard pulley off a 2013 truck application, nothing special.

GM and aftermarket both show solid pulley for 2013. Do you happen to remember what type of truck it was?

Thanks in advance,

Rob

GM and aftermarket both show solid pulley for 2013. Do you happen to remember what type of truck it was?

Thanks in advance,

Rob

- Thread starter

- #703

still amazed at your attention to detail extremely clean,

just noticed the winch on the pass frame in the engine compartment, ???? pull the axle up????

Yes, I have a small 3k winch in the front to duck down the front suspension when needed. I'm not sure it is 'needed' but it was a lot easier to add at this stage.

Sorry updates have been lacking. Facebook and Instagram make it so easy and quick. If you want a daily fix check that out @brennanmetcalf. I have been doing a lot of finish work lately....wiring, plumbing, etc.

- Thread starter

- #704

It is a standard pulley off a 2013 truck application, nothing special.

GM and aftermarket both show solid pulley for 2013. Do you happen to remember what type of truck it was?

Thanks in advance,

Rob

2013 1500 quad cab short bed 4wd. I have the vin around if that would help.

2fpower

SILVER Star

She's alive!!!

- Thread starter

- #706

Time to get caught back up again....wholy carp what a last few months it has been. I had a firm date I needed to make for a Rubicon trail trip along with another commitment ( more on that later ), so I really thrashed for the last two months to get this thing together enough.

This is about where I left things. Getting color on the tub was a HUGE step. The paint isn't perfect, I learned a ton along the way, but it is one color and not rattle can.

Things like this added a TON of hours along the way. When your 'good' hood has a lot more filler in it than you think it did. I knew it has some, but the more I stripped off the worse and worst it got. These hoods, and cruiser parts in general, are just silly expensive typically. I don't know if I would build another one because of that.

Eventually I got it stripped down to bare metal again. It doesn't look bad, but it needed a LOT of attention.

As I worked on supporting parts I continued to do final assembly on the tub. This included the tunnel, shifters, pedals, etc.

I also had to sort out stuff like this, odd brake plumbing issues while trying to retain as much of the 80 series system as possible.

With everything tucked so tight in the chassis with the flat belly and V8 exhaust, I had to get a little creative with routing for the brake and fuel lines. That included making stone guards like this where they where going to be exposed to the outside of the frame rail.

I used Earls VaporGuard line for the entire fuel system from the custom aluminum tank to the engine. I used a 2006 GM fuel pump sending unit that has the filter and regulator internal to the assembly. With my returnless engine fuel system, all I needed to do was route a single line from the pump to the engine. The line was routed as carefully as possible with isolated supports, rub guards, stone guards, and DEI heat wrap anywhere close to the exhaust system heat.

This is about where I left things. Getting color on the tub was a HUGE step. The paint isn't perfect, I learned a ton along the way, but it is one color and not rattle can.

Things like this added a TON of hours along the way. When your 'good' hood has a lot more filler in it than you think it did. I knew it has some, but the more I stripped off the worse and worst it got. These hoods, and cruiser parts in general, are just silly expensive typically. I don't know if I would build another one because of that.

Eventually I got it stripped down to bare metal again. It doesn't look bad, but it needed a LOT of attention.

As I worked on supporting parts I continued to do final assembly on the tub. This included the tunnel, shifters, pedals, etc.

I also had to sort out stuff like this, odd brake plumbing issues while trying to retain as much of the 80 series system as possible.

With everything tucked so tight in the chassis with the flat belly and V8 exhaust, I had to get a little creative with routing for the brake and fuel lines. That included making stone guards like this where they where going to be exposed to the outside of the frame rail.

I used Earls VaporGuard line for the entire fuel system from the custom aluminum tank to the engine. I used a 2006 GM fuel pump sending unit that has the filter and regulator internal to the assembly. With my returnless engine fuel system, all I needed to do was route a single line from the pump to the engine. The line was routed as carefully as possible with isolated supports, rub guards, stone guards, and DEI heat wrap anywhere close to the exhaust system heat.

- Thread starter

- #707

More....

Doing things like brake lines always takes forever to make it not look like an after thought. As you progress through the build it is hard not to get backed into corners with some of this stuff. You end up just having to think as far ahead as you can and make the best of the space you have left when you get that far.

I cool trick I picked up from a local autobody guy. A heavy solution of dawn dish soap will soften up and reverse aging on rubber material like the window seal gasket. I let mine soak for a good 3-4 days.

After a quick, and poorly timed, trip back to the vendor for some thread improvement, I was finally able to install the heavy duty steering linkage.

More painting. I definitely didn't give myself enough time for this. It takes forever, especially with some used parts.

Getting the bed frame back on by myself as super fun. Having to remove the wheel/tire half way through was awesome.

While I had decided to have someone else tackle the engine wiring harness, I decided to make my own body harness from scratch. This firewall panel was the base for that system. I am using a 10+10 Bussman fuse block and HD maxi fuse protected relay pack to drive it. All the cabin wiring passes through the Seals-it grommet for bi-directional routing. In theory the entire harness can be pulled out by removing this panel from the tub and unplugging switches in the cabin.

Doing things like brake lines always takes forever to make it not look like an after thought. As you progress through the build it is hard not to get backed into corners with some of this stuff. You end up just having to think as far ahead as you can and make the best of the space you have left when you get that far.

I cool trick I picked up from a local autobody guy. A heavy solution of dawn dish soap will soften up and reverse aging on rubber material like the window seal gasket. I let mine soak for a good 3-4 days.

After a quick, and poorly timed, trip back to the vendor for some thread improvement, I was finally able to install the heavy duty steering linkage.

More painting. I definitely didn't give myself enough time for this. It takes forever, especially with some used parts.

Getting the bed frame back on by myself as super fun. Having to remove the wheel/tire half way through was awesome.

While I had decided to have someone else tackle the engine wiring harness, I decided to make my own body harness from scratch. This firewall panel was the base for that system. I am using a 10+10 Bussman fuse block and HD maxi fuse protected relay pack to drive it. All the cabin wiring passes through the Seals-it grommet for bi-directional routing. In theory the entire harness can be pulled out by removing this panel from the tub and unplugging switches in the cabin.

- Thread starter

- #708

Juvenile exhaust system, check. There is no mistaking this is a stout V8. I will get tired of it, but it works for now.

Another key part of the wiring system. With the battery behind the cab, I needed a common point to route and distribute power and ground without having to add five feet of wiring to ever circuit.

I used making tape to experiment with pre-routing the chassis/body wiring before drilling holes to use pine tree replaceable zip-tie fasteners. This basically gave me a 'racetrack' to route everything for the wiring.

I ended up building from the ends inward with sub-harnesses for most of the major circuits. This will hopefully let me replace things in the future if needed. All the connectors are 150-series Metri-Pack connectors. Each wire was color coded with an identifying stripe AND tagged with a heat shrink label on both sides of the connector.

Here you can see the major trunk run of wires in the cabin space during the wiring process. I tried to keep everything as clean as possible, but even in my rather 'basic' wiring harness it was very surprising how fast things 'grew' in size and scope.

New battery, the Optima was pretty 'meh' after sitting for so long. This location worked out pretty well and kept the weight rather low and balanced.

Another super fun thing along the way was having to reverse engineer the E-locker wiring. It turns out the Lexus chassis had all it's own colors for the wiring harness. In the end it worked out fine, but I was NOT happy about it in the middle.

Eventually I started filling in the details like the gauge mount, switches, etc. It was a really good feeling when I finally got to function test all the wiring in the chassis/body harness for function.

- Thread starter

- #709

Even in thrash mode, I enjoy making stuff like this. I was able to convert a vacuum actuated 4-way heater valve to cable. I can even swap all the parts over to a new valve if needed in the future with no mods.

The 4-way heater valve helps keep heat out of the cabin by diverting coolant back to the engine.

Another fun one. After wondering around Walmart for a few hours I found the perfect $3 water bottle to make an overflow/recovery tank out of. I fabbed a small bracket to hold it to the shroud and turned a custom aluminum neck adapter on the lathe. In the end it fit perfect....

About at this point things started to get really interesting ( read super frustrating ). After fighting through an issue with a 'frozen' fuel pump regulator for a day or two, I started finding issues in my wiring harness.

The short version, I ended up having to repin the gas pedal at the ECM and at the pedal to get it to work right.

Sadly that was only the beginning also. The engine ran, but not well, after much looking....including purchasing my own HPtuner dongle....I found that the O2 sensors where LOOMED backwards in the harness. After re-pinning both of those in at the ECM plug things got a LOT better.

I also had to plumb the entire OBA system ( and the wiring controls ) in there somewhere. I came up with a neat way to do a pressure bleed down on the compressor output line using a micro sized orifice valve along the way.

Warn Industries was nice enough to rebuild my 8274 to current specs. These old style winches just look perfect on the front of 'older' rigs like this.

- Thread starter

- #710

I was like goldilocks with the rear springs. I ended up with 3 sets of rear springs to find something that made me happy. The magic combination so far si using TWO short side factory LX450 rear springs. That gave me the 5" of uptravel I was looking for for the rear suspension when loaded for a decent trip.

The rear suspension also got a set of stem top universal Fox 2.0 Resi shocks with 10.1" of travel from Accutune....

The front got Fox 2.0 Resi 10.6 inch stem-stem units that where originally for a lifted Nissan Patrol application. Accutune also valved these custom for me.

I really wanted bolt in shocks with factory like isolation.....no rod ends.

Somewhere along the way I made some sweet floor mats out of thick rubber barn mats from Tractor supply. These are held to the floor with small 6mm flat head fasteners mated to pre-positioned weld nuts in the floor and tunnel.

I also ended up completely re-engineering the factory wiper system to use a Jeep TJ wiper motor so I could have dynamic park and intermittent wipe using a Cole-Hearse switch that looks really factory. It also drives a washer pump. Details Details.

- Thread starter

- #711

Because of the thrash at the end....working till midnight or later for weeks on end....I didn't take as many pictures as I would have liked.

This is what the windshield looked like assembled. I ended up having to make a love it or hate it wiper motor cover for the larger Jeep TJ motor.

Thing like the defrost cover where done on the fly with almost no pre-planning. In the end, these parts where some of my favorite things in the build.

Or how about a glove box door with a locking cam latch....

Things like the marine plywood bed floor are not my favorite, but in the end it actually came together WAY better than I thought it would.

TADA! The last 2-3 days where a complete blur as I assembled this thing on only a few hours sleep a night. At this point I was still dealing with the engine wiring issues too. The astute observers will also note another big change.....wheels and tires.

I was approached by Milestar tires to do some testing for them on their new 40" Patagonia Black Label tire. This is something 'new' in my opinion that deserved some attention. These are really a neat idea....more on that later....

Well that catches us up on vehicle building, now lets go on an adventure....or two.....

This is what the windshield looked like assembled. I ended up having to make a love it or hate it wiper motor cover for the larger Jeep TJ motor.

Thing like the defrost cover where done on the fly with almost no pre-planning. In the end, these parts where some of my favorite things in the build.

Or how about a glove box door with a locking cam latch....

Things like the marine plywood bed floor are not my favorite, but in the end it actually came together WAY better than I thought it would.

TADA! The last 2-3 days where a complete blur as I assembled this thing on only a few hours sleep a night. At this point I was still dealing with the engine wiring issues too. The astute observers will also note another big change.....wheels and tires.

I was approached by Milestar tires to do some testing for them on their new 40" Patagonia Black Label tire. This is something 'new' in my opinion that deserved some attention. These are really a neat idea....more on that later....

Well that catches us up on vehicle building, now lets go on an adventure....or two.....

Looks sharp! Thanks for your help with the ps pulley. I would like to see how the new tires do. I have not wheeled with anyone with them but have seen them around the last year or so.

- Thread starter

- #713

Day 0. I delayed my departure by a day or three because I was still

assembling the truck. I put about 3 miles on it around the

neighborhood in testing. I built another HF tool kit for this one with

a lot more metric, but basically similar to what I had in the flatty

for UA. Overall though, I didn't have jack for spare parts really

other than a driveshaft ( which fits both ends ) and a spare tire. One

thing I noticed, I REALLY took for granted how well packaged

everything in the flat fender is. I probably haven't changed much in

the last 4 years. I know where things are, where they go, etc. I had

ZERO of that in the Lexus and that was annoying. It takes time to

develop a packing system that is somewhat logical and organized. The

Lexus is pretty small, I need to develop a better plan for storing

things for sure. The cabin space fills up pretty quickly. I didn't

want a ton of stuff in the bed because of the weather.

Hey look....Utah.....or was this Nevada.....

Day 1. I packed up the night before and was ready to leave by 1st

light pretty much. I believe I left the house just after 7am. The goal

was to get to Travis's house in Round Mountain, Nevada, which was 733

miles away. Once on the road it was pretty apparent that this little

truck is a completely different animal than my flat fender. This thing

WANTS to go down the road. It will go as fast as you want generally,

going 5+ over the speed limit is easy up and down just about anything.

The only real issues this first day where filling the gas tank and the

transmission shifting was a bit off. The hidden gas filler neck thing

looks super sweet, but it is VERY slow to fill. You basically have to

shoot the fuel into the hole at a pretty slow rate to keep it from

burping back up the filler neck. The good thing is that with a 25+

gallon tank that you don't have to do it often, but when you do fill

it, it takes a long time. I was able to set up the AeroForce

Interceptor before leaving to do it's cycle scan function. This allows

me to watch 8 engine/transmission functions in a 2x4 timed rotation.

Being able to watch so many things made me feel a lot better.

A big win with this rig is that the cooling system for the engine and

transmission are rock solid. The engine runs 190-195F 99.9% of the

time. The transmission runs 165-170F. The only time I see higher temps

is if shut it off and let things heat soak. As soon as the vehicle is

started again the temps fall quickly back into the normal zone. I was

pretty worried about this with only a 24x19 radiator on an LS engine.

I also didn't do any of the fancy surge tank stuff. My first day

included driving up passes at 5 over the speed limit passing just

about everyone in 4th gear at 3000+rpm. Engine and trans temps hold

really well. I do believe that the hood louvers evacuate a HUGE amount

of heat from the engine compartment. Even with complete inner fenders

and the engine intake over the passenger side exhaust manifold, I

never saw high intake temps. They seemed to be about 120F at

most......and that included 95+F degree sunny weather in Nevada.

Oh....the other failure. This truck is fast enough, with bad enough

aero, that it basically folds the side mirrors in at highway speeds. I

need to get some better quality TJ mirrors, probably OEM units, to

try.

It's not as quiet as I thought it would be, basically wind noise. I

still have some work on the doors to do. I kinda had to trash to get

them installed. I will need to spend some more time getting them

adjusted better. They do get pulled around in the wind a bit,

basically like oem jeep soft upper doors. I will probably have to add

something on the inside upper rear corner to keep the seal tight at

60+ mph.

The transmission tune was pretty aggressive for 4-6th. It basically

didn't like going into 5th till about 60mph.....and 6th didn't happen

till 73mph or so. This was kinda annoying. This did get better over

the course of the trip as the transmission did a bit of 'learning' I

think.

I ended up making the entire 733 miles in about 12.5 hours without any

issues. I actually ended up staying up to about midnight helping my

friend Travis thrash on his truck.....and we worked on it another 4-5

hours the next morning too. So....the truck isn't too fatiguing to

drive or anything. I REALLY want cruise control however. I need to

find a way to get the BCM module back in the harness like I originally

planned, but the harness guys couldn't make happen.

700+ miles later.....safe arrival......

Day 2. After working on Travis's old Ford for the morning, I finally

had to push him to leave basically. With his no-overdrive, older v8

engine, 5.38 gears, and 37" tires he was limited to 55mph pretty much,

I think he got up to 60mph once or twice. I made it about 20 minutes

out of town before I told him he needed an overdrive. I think this was

some weird karma thing that had something to do about my flat fender

being so slow on the highway. Driving the Lexus at 55mph is kinda

boring. With cruise it would have been better. It really wants to go

faster.

Nothing bad happened for either of us really. I did decide to pull out

my 'stuck on high' LED headlights and stick some regular 7" round

headlights from Autozone while Travis did some last minute shopping at

Tractor Supply for a few things. Doing that, I did manage to slip with

a screwdriver and take a BIG chunk our of my hand. Ouch. Once I had

regular lights in the truck, high/low worked fine. Weird.

Oh. I did notice I have a bit of a 'buzz' at 55-57mph. It might be a

harmonic thing with the poly motor mounts, but I think the front

driveline might need a slight angle/caster adjustment. I may have to

pull the front driveshaft to test that theory. The day before I just

didn't drive enough at those speeds to notice.

We got into Phil's place in Minden about dusk and the rest of the crew

had just gotten there too. We visited pretty late into the evening

with everyone.

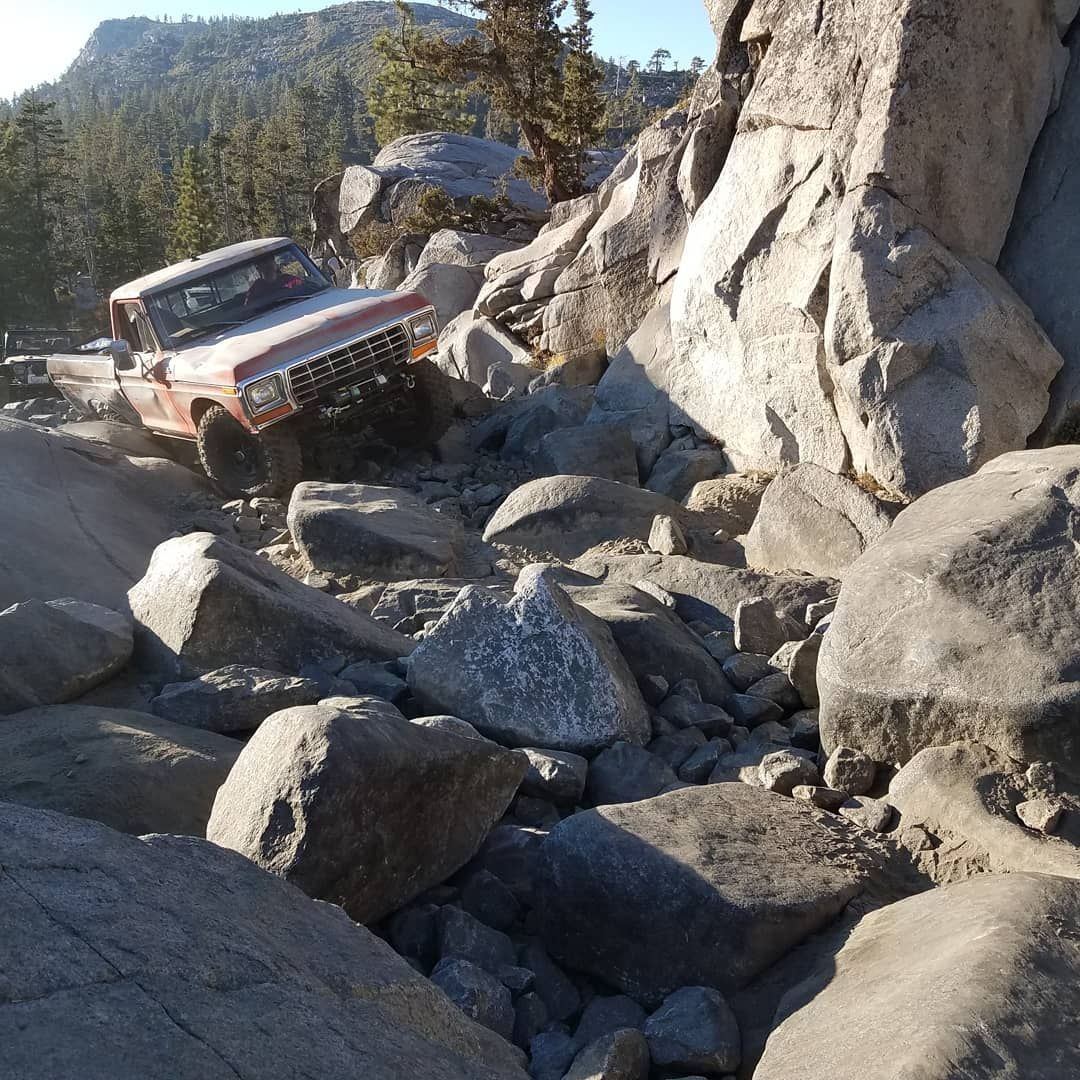

Day 3. Rubicon Day one. We got out of Minden pretty early in the

morning, but is a decent drive around to the Wentworth side from

Minden, NV. We decided to go in that side to get more of the original

Rubcion experience. I think the Wentworth side entrance is a little

more difficult than the loon side...and sees less traffic. I had also

called Tim Hardy the day before and got him to come out for the day

with us. I think that made my friend Travis's decade. Tim brought the

Grand Vitaria, which he promptly broke about a bit past Wentworth

Campground. He ended up parking it where he could get out in 2wd and

rode along with Phil for a bit.

Other than my driveway, this was the 1st time I had the Lexus in low

range. Unfortunately, low range was acting pretty dang dumb. It just

wasn't shifting right. It would basically get kinda 'lost' in 3rd thru

6th eventually. I ended up figuring out that if I put the shifter in M

mode right after the 1-2 shift it would operate between those gears in

low range normally. That worked fine for the slower speed of the

Rubicon, but I was pretty bummed it wasn't working right. One of the

things I was looking forward to with the 6L80E was the ability to do

about 60 in low range if I wanted.

Other than that the trail was tons of fun. The truck, other than low

range shifting, was working very well. It did take a bit of getting

use to, it feels VERY different from my old flat fender for SURE. I

did jump into the deep end a bit on the Wentworth side, but the truck

handled it just fine. No damage to anything other than scuffed paint

on the rockers and the belly pan got a few scratches. I was even able

to do soup bowl on my 1st try....that was pretty sweet. I was the only

one in the group to make it.

We ended up getting all the way to Buck Island Lake at just about

dark. We found out Travis had popped his short side front axle shaft

about a mile before buck just as you start down the slab section. It

took a little bit of extra spotting to get him to Buck in 3wd.

Everyone was pretty worn out by then after a long day. It was awesome

of those fine upstanding gentleman camped across from us to blast

their music till 2am for us and have a roaring campfire during a fire

ban during one of the worst fire seasons in a decade.

Storage organization still needs work. I still like having gear stored

inside the spare tire, more smaller dry bags would work better than

large ones. I do really like my simple LED bed light and dome light

combo. That makes unpacking for camp in the dark easy. I really want

to build my idea for a collapsible hammock frame that attaches to the

bumpers.

Day 4. Rubicon day two. We got out of camp pretty early in the

morning. The group was a little worried about getting Travis down to

Rubicon Springs, but that ended up being a non-issue. The day went

pretty smooth. There where some tight spots. Travis needed a tug or

two but for a fool-size with 3wd it did fine!

We actually made it to Rubicon Springs by about 1pm. With Travis

having only 3wd and weekend traffic likely coming in, we decided to

push on up Cadillac Hill to make sure we could get the big ford up and

out. Worst case we planned on camping at the top, and best case head

all the way back to Minden a little early so everyone could start

their long drive home back north.

The Caddilac Hill section actually went pretty easy for everyone. The

big peg leg ford needed a few tugs, but I can't really fault it. We

had a mini-snafu meeting a group that was coming down in for the

weekend. They got a little worked up as everyone got shifted around to

let everyone pass. It wasn't a big thing really, but it was a thing.

In the end it worked out fine. We ended up getting all the way back to

Minden that evening. I have to say, the exit road to the staging area

wasn't my favorite, it reminded me of the exit road to

Pritchett.....long, bumpy, and dusty. Meh. I had fleeting thoughts of

just turning around and going back out to Loon!

I had to head south though!

assembling the truck. I put about 3 miles on it around the

neighborhood in testing. I built another HF tool kit for this one with

a lot more metric, but basically similar to what I had in the flatty

for UA. Overall though, I didn't have jack for spare parts really

other than a driveshaft ( which fits both ends ) and a spare tire. One

thing I noticed, I REALLY took for granted how well packaged

everything in the flat fender is. I probably haven't changed much in

the last 4 years. I know where things are, where they go, etc. I had

ZERO of that in the Lexus and that was annoying. It takes time to

develop a packing system that is somewhat logical and organized. The

Lexus is pretty small, I need to develop a better plan for storing

things for sure. The cabin space fills up pretty quickly. I didn't

want a ton of stuff in the bed because of the weather.

Hey look....Utah.....or was this Nevada.....

Day 1. I packed up the night before and was ready to leave by 1st

light pretty much. I believe I left the house just after 7am. The goal

was to get to Travis's house in Round Mountain, Nevada, which was 733

miles away. Once on the road it was pretty apparent that this little

truck is a completely different animal than my flat fender. This thing

WANTS to go down the road. It will go as fast as you want generally,

going 5+ over the speed limit is easy up and down just about anything.

The only real issues this first day where filling the gas tank and the

transmission shifting was a bit off. The hidden gas filler neck thing

looks super sweet, but it is VERY slow to fill. You basically have to

shoot the fuel into the hole at a pretty slow rate to keep it from

burping back up the filler neck. The good thing is that with a 25+

gallon tank that you don't have to do it often, but when you do fill

it, it takes a long time. I was able to set up the AeroForce

Interceptor before leaving to do it's cycle scan function. This allows

me to watch 8 engine/transmission functions in a 2x4 timed rotation.

Being able to watch so many things made me feel a lot better.

A big win with this rig is that the cooling system for the engine and

transmission are rock solid. The engine runs 190-195F 99.9% of the

time. The transmission runs 165-170F. The only time I see higher temps

is if shut it off and let things heat soak. As soon as the vehicle is

started again the temps fall quickly back into the normal zone. I was

pretty worried about this with only a 24x19 radiator on an LS engine.

I also didn't do any of the fancy surge tank stuff. My first day

included driving up passes at 5 over the speed limit passing just

about everyone in 4th gear at 3000+rpm. Engine and trans temps hold

really well. I do believe that the hood louvers evacuate a HUGE amount

of heat from the engine compartment. Even with complete inner fenders

and the engine intake over the passenger side exhaust manifold, I

never saw high intake temps. They seemed to be about 120F at

most......and that included 95+F degree sunny weather in Nevada.

Oh....the other failure. This truck is fast enough, with bad enough

aero, that it basically folds the side mirrors in at highway speeds. I

need to get some better quality TJ mirrors, probably OEM units, to

try.

It's not as quiet as I thought it would be, basically wind noise. I

still have some work on the doors to do. I kinda had to trash to get

them installed. I will need to spend some more time getting them

adjusted better. They do get pulled around in the wind a bit,

basically like oem jeep soft upper doors. I will probably have to add

something on the inside upper rear corner to keep the seal tight at

60+ mph.

The transmission tune was pretty aggressive for 4-6th. It basically

didn't like going into 5th till about 60mph.....and 6th didn't happen

till 73mph or so. This was kinda annoying. This did get better over

the course of the trip as the transmission did a bit of 'learning' I

think.

I ended up making the entire 733 miles in about 12.5 hours without any

issues. I actually ended up staying up to about midnight helping my

friend Travis thrash on his truck.....and we worked on it another 4-5

hours the next morning too. So....the truck isn't too fatiguing to

drive or anything. I REALLY want cruise control however. I need to

find a way to get the BCM module back in the harness like I originally

planned, but the harness guys couldn't make happen.

700+ miles later.....safe arrival......

Day 2. After working on Travis's old Ford for the morning, I finally

had to push him to leave basically. With his no-overdrive, older v8

engine, 5.38 gears, and 37" tires he was limited to 55mph pretty much,

I think he got up to 60mph once or twice. I made it about 20 minutes

out of town before I told him he needed an overdrive. I think this was

some weird karma thing that had something to do about my flat fender

being so slow on the highway. Driving the Lexus at 55mph is kinda

boring. With cruise it would have been better. It really wants to go

faster.

Nothing bad happened for either of us really. I did decide to pull out

my 'stuck on high' LED headlights and stick some regular 7" round

headlights from Autozone while Travis did some last minute shopping at

Tractor Supply for a few things. Doing that, I did manage to slip with

a screwdriver and take a BIG chunk our of my hand. Ouch. Once I had

regular lights in the truck, high/low worked fine. Weird.

Oh. I did notice I have a bit of a 'buzz' at 55-57mph. It might be a

harmonic thing with the poly motor mounts, but I think the front

driveline might need a slight angle/caster adjustment. I may have to

pull the front driveshaft to test that theory. The day before I just

didn't drive enough at those speeds to notice.

We got into Phil's place in Minden about dusk and the rest of the crew

had just gotten there too. We visited pretty late into the evening

with everyone.

Day 3. Rubicon Day one. We got out of Minden pretty early in the

morning, but is a decent drive around to the Wentworth side from

Minden, NV. We decided to go in that side to get more of the original

Rubcion experience. I think the Wentworth side entrance is a little

more difficult than the loon side...and sees less traffic. I had also

called Tim Hardy the day before and got him to come out for the day

with us. I think that made my friend Travis's decade. Tim brought the

Grand Vitaria, which he promptly broke about a bit past Wentworth

Campground. He ended up parking it where he could get out in 2wd and

rode along with Phil for a bit.

Other than my driveway, this was the 1st time I had the Lexus in low

range. Unfortunately, low range was acting pretty dang dumb. It just

wasn't shifting right. It would basically get kinda 'lost' in 3rd thru

6th eventually. I ended up figuring out that if I put the shifter in M

mode right after the 1-2 shift it would operate between those gears in

low range normally. That worked fine for the slower speed of the

Rubicon, but I was pretty bummed it wasn't working right. One of the

things I was looking forward to with the 6L80E was the ability to do

about 60 in low range if I wanted.

Other than that the trail was tons of fun. The truck, other than low

range shifting, was working very well. It did take a bit of getting

use to, it feels VERY different from my old flat fender for SURE. I

did jump into the deep end a bit on the Wentworth side, but the truck

handled it just fine. No damage to anything other than scuffed paint

on the rockers and the belly pan got a few scratches. I was even able

to do soup bowl on my 1st try....that was pretty sweet. I was the only

one in the group to make it.

We ended up getting all the way to Buck Island Lake at just about

dark. We found out Travis had popped his short side front axle shaft

about a mile before buck just as you start down the slab section. It

took a little bit of extra spotting to get him to Buck in 3wd.

Everyone was pretty worn out by then after a long day. It was awesome

of those fine upstanding gentleman camped across from us to blast

their music till 2am for us and have a roaring campfire during a fire

ban during one of the worst fire seasons in a decade.

Storage organization still needs work. I still like having gear stored

inside the spare tire, more smaller dry bags would work better than

large ones. I do really like my simple LED bed light and dome light

combo. That makes unpacking for camp in the dark easy. I really want

to build my idea for a collapsible hammock frame that attaches to the

bumpers.

Day 4. Rubicon day two. We got out of camp pretty early in the

morning. The group was a little worried about getting Travis down to

Rubicon Springs, but that ended up being a non-issue. The day went

pretty smooth. There where some tight spots. Travis needed a tug or

two but for a fool-size with 3wd it did fine!

We actually made it to Rubicon Springs by about 1pm. With Travis

having only 3wd and weekend traffic likely coming in, we decided to

push on up Cadillac Hill to make sure we could get the big ford up and

out. Worst case we planned on camping at the top, and best case head

all the way back to Minden a little early so everyone could start

their long drive home back north.

The Caddilac Hill section actually went pretty easy for everyone. The

big peg leg ford needed a few tugs, but I can't really fault it. We

had a mini-snafu meeting a group that was coming down in for the

weekend. They got a little worked up as everyone got shifted around to

let everyone pass. It wasn't a big thing really, but it was a thing.

In the end it worked out fine. We ended up getting all the way back to

Minden that evening. I have to say, the exit road to the staging area

wasn't my favorite, it reminded me of the exit road to

Pritchett.....long, bumpy, and dusty. Meh. I had fleeting thoughts of

just turning around and going back out to Loon!

I had to head south though!

You might want to call Jim at Zero Gravity Performance. He does a lot off tuning on 6l80's. He did the tune for my Ultra4 race car. I have tap shift as well. and yes, I have done 78 mph in 5th gear with 6th still to go in low range! Makes it great if you pop out on a road and need to get down the road to the next trail and do not want to shift. Without the tune it does like you describe and always wants to upshift to the highest gear and is not fun on the trail. I also picked up the LED display to show what gear I am in. And I can start off in 1st, 2nd, or 3rd now. Talk with him, let him know how you want to drive it and he can build you a tune, even full manual mode.

Rob

Rob

- Thread starter

- #716

You might want to call Jim at Zero Gravity Performance. He does a lot off tuning on 6l80's. He did the tune for my Ultra4 race car. I have tap shift as well. and yes, I have done 78 mph in 5th gear with 6th still to go in low range! Makes it great if you pop out on a road and need to get down the road to the next trail and do not want to shift. Without the tune it does like you describe and always wants to upshift to the highest gear and is not fun on the trail. I also picked up the LED display to show what gear I am in. And I can start off in 1st, 2nd, or 3rd now. Talk with him, let him know how you want to drive it and he can build you a tune, even full manual mode.

Rob

I've talked with Jim a few times now.

What control system are you running? Are you using just the factory TCM in the trans or do you have one of the PCS translator boxes too?

How do you start off in 1-3rd. Are you using the gates below M to allow more functions?

Mine had a tune, just not a great one. V2 from the tuner has been a lot better, but I haven't put as many miles on it. This tune seems to work well up to 50mph in low range so far, but above 50 it wants to kick back to 5th. High range is a lot less aggressive in 4-6th which is nice too.

I have an AeroForce Interceptor obd2 gauge that lets me read current gear, and just about everything else on the CAN network that I want.

As soon as I figure out some plugs/pins for the BCM module I will have tap shift, cruise, tow/haul, etc. Not many people want to work with the factory BCM however which is a headache.

I am running the factory TCM with his tune. I do have a seperate Toggle switch to shift gears. It has resistors in-line to act as the factory set up. I would have to look up the resistor OHMs to figure it out. My friend Dave Smiley was one of the first ones I know that did this in his car. He helped me with the wiring. I have a 4 spd shifter. When I go to 3rd it goes to manual mode then I tap shift. It also has an agressive tune in that mode as well. Jim should be able to explain it more.

Heading to Rausch Creek for the weekend and need to get back to packing. PM me if you have any more questions, I am happy to help.

Heading to Rausch Creek for the weekend and need to get back to packing. PM me if you have any more questions, I am happy to help.

- Thread starter

- #718

Road trip part B

I was really fortunate to be invited down to the Off Road Expo show in Pamona, California by Milestar Tire to display the #LX45 in their booth. I was a really awesome experience overall, and another bucket list item to check off for me. I have to admit, I was very nervous to have thousands of people, including some BIG industry players look over my little garage build. In the end it went great. I actually got to work into the booth both days and interact with people asking questions about the build. Lots of people where very impressed that I drove it.....now some 1650 miles out to the show.

The return trip back home to Colorado brought the final total for the shakedown run to just over 2400 miles!

Overall, for a first run, I couldn't be happier.

Some more reflection and review of the build from my notes....

The suspension of this thing is a TOTALLY different league from the

flat fender. I hope you get to go for a ride in it to compare to your

TJ. The road manors are really good. It is easy to drive on the

highway at modern 70-80mph speeds with one hand on the wheel and it

doesn't require constant attention. It doesn't seem to wander. There

is no steering wheel shimmy or shake. It doesn't seem to need a front

sway bar. You can toss it around pretty good and exceed most posted

corner speed signs without any issues.

The spring rates seem to be good, even the rear end ( which I thought

was going to be too stiff ). The stance is just about what I would

want. For REALLY big trips with more gear I might even swap in the

taller rear springs. The other really nice thing....it doesn't seem to

bottom out, or at least I can't feel it. I can't tell when the front

foam bumpstops engage either, they just basically 'catch' the axle

without any noise or drama which is so nice. I didn't notice the rear

suspension bottom out either, and it doesn't even have the big foam

stops yet. I think the good shocks really help and probably the best

thing is a decent amount of uptravel. I ended up with ~6" in front and

5" on the rear suspension ( 10.6 front shock travel, 10.1 rear shock

travel ).

In the entire 2400 mile trip I only had one butt-pucker moment on the

road. I was passing a group of motor-homes on a 2-lane highway in the

four corners area. This is basically on the 'res' and the roads are

crap. I was going about 75-85mph during the pass and hit a section of

repaired road with big 'rollers' in the pavement. I think any vehicle

would have gotten tossed around a bit.....getting tossed around a bit

on 40s at 23psi is a bit interesting. It was the only time I

specifically remember needing both hands on the wheel and having to

'try' and drive it through the issue. I think the rollers where big

enough and spaced just right to act basically like big whoops. I'm not

saying I went airborne.....but that is what it felt like....

The tires don't rub.....much....on the body. The rear tires just KISS

the lower edge of the fender when it is twisted all the way up. The

inside of one tire rubs on the bed panel a little....but the other

doesn't. I think it has something to do with how the panhard allows

the suspension to articulate. The front tires don't rub anything that

I could detect lock to lock. This is also with the new wheels which

have a bit more backspacing than I originally built it with. I think

the original wheels would make things even better.

Off road I really like the suspension also. I didn't get to do much

spirited driving yet, the Rubicon isn't really like that, but what

little I did felt really nice. Using all OEM bushings in everything

seemed like a big plus. There isn't any squeaking or clunking in the

suspension as it articulates or hits bumps.

The only real downside to the suspension I have found is how exposed

the rear frame side lower control arms are. They get hit. You can

drive around them to a degree, but you still hit them. I should

probably get them plated in a layer of 1/8-3/16 material in the

critical area. That would be a good winter project.

The vehicle seems to WANT to climb things. I think it is a lot of

things coming together.....suspension geometry, weight bias, lower

overall weight, etc. Overall I really like the vehicle size and

wheelbase. It feels bigger than the flat fender, but not HUGE. I was

the only one in the group to make Soup Bowl on the Rubicon. That felt

really good, especially with no seat time.

Gearing. Overall I am pretty dang happy. I think it could be tweaked a

little, but I think it would be a trade off generally. High range is

really pretty good. It could be a touch lower I think, but I wouldn't

want to drastically change it....maybe something like 5.38 instead of

5.00 would be better on the highway, but honestly I am not sure. It

works pretty well. I do still want to try something like 6-7:1 gearing

in the axles on a build like this at some point, especially with the

6-10 speed transmissions. The new transmission tune feels even better.

I don't think higher gears in the axles would be what I want. I don't

think I would do 4.88s with 40+ tires and a 6L80E at this point. That

is kind of a shame actually, I think the 6L80e really needs about a

2.5-2.7 low range. 2:1 probably isn't deep enough unless you want to

try 6-7:1 in the axles. 3:1 is getting too low where I think the crawl

ratio is getting too short. For future builds this is an interesting

conundrum honestly. You can't get an atlas with 2.5 gearing. My low

range gearing feels REALLY good. It is low enough to have fine

control, but not so low it is pushing you through the brakes all the

time and taking all the magic out of the torque converter. It will be

interesting to get it into different terrain. I have a feeling for

climbs I have to bump, I am going to need to force the transmission to

be able to start in 2nd low. I am a pretty firm believer still,

especially after building this one, that the sweet spot for an

automatic ( with a proper amount of power ) is about 50-55:1 with a

40-42" tire. I am 54:1 in the Lexus. I do notice a bit of torque

'lean', or rather that the chassis is loaded up more, with more

upstream gearing vs downstream gearing. I am only running 4.10s in the

axles. For future builds, I would rather have more gearing in the

axles and less gearing in the transmission and t-case generally. I

think this calms the chassis down when doing dumb stuff. The Lexus

isn't bad, but I can feel it.

Steering. Overall I am happy, but it still needs some tweaking. The

steering wheel feels a bit heavy. I'm not sure if this is a pressue or

flow issue. The steering never seems to run out of force, it turns the

tires whenever you want, even with the tires aired down and the front

diff locked. It just feels a bit heavy. At speed with the engine rpms

up you don't notice it at all. The steering wheel feel on the road at

speed is actually very good. I really like that the steering doesn't

squeak at all. I might have to try some pump mods in the future. The

steering angle capability is also very nice. It turns lock to lock

with 40s. That makes the 112" wheelbase much more maneuverable than I

thought it would be. It is longer no doubt, but I didn't find myself

having to 3 point much if at all.

Lockers. The selectable lockers are ok. I left the center diff locked

99% of the time. I honestly didn't have to use the diff locks as much

as I thought I would. I did start to experiment more with different

combinations of locker use the 2nd day on the Rubicon. In one spot I

even tried a front 'dig' kinda thing to get the front end to slip

down, and that actually seemed to work pretty well. I basically kicked

out the center diff lock and grabbed the ebrake. That seemed to allow

me to force the vehicle to pull more with the front end and slip the

front axle sideways down off a big rock wall when trying to turn at

the same time. I also played with using the front or rear locker only

in mild situations. I still think that front locker only seems to work

better than rear locker only to me. Waiting for the lockers to engage

or disengage was kinda annoying, but it isn't bad. I have the locker

switch icon wired to the fork position switch on the elocker diff. I

can see exactly when the locker changes....and you can hear it click

typically. The toyota elockers actually work pretty well overall. They

seem to lock and unlock ok.

To muse about future builds. For a vehicle that is part time 4wd. I

would lean heavily toward running an automatic front locker with

selectable rear locker like the flatty. That combo just seems to work

better with less driver input required. Add in a t-case and front axle

that would hold up to front front digs. Add in rear left/right cutting

brakes and maybe another trick or two with the brakes. I think the

automatic front locker does a better job at locking and unlocking in

the medium stuff vs the driver having to turn the selectable locker on

and off. This is me just chasing unicorns to a degree. Both combos are

probably equally capable, its just preference about how the vehicle

handles the medium hard stuff.

Power. The 5.3 feels about right, but isn't a silly amount of power.

It is enough to be fun. It is enough to get up any hill on the highway

at extra legal speeds on 40s. That is about 325hp. That is honestly

pretty darn good. I'm not saying that I wouldn't give about 400hp a

try in the next one. I've driven the Summer Camp jeep with 525ish? It

was fun, but I think I got to 1/2 throttle maybe. In this build, I

wouldn't want much more on this chassis.....but I am happy I did a v8.

The low 1st gear in the 6l80e makes it feel like more and really helps

get things moving.

Cooling. I am VERY happy with how the cooling system worked out. I

haven't noticed any issues at all. It runs on thermostat and the

transmission doesn't heat up. I need to set the alarms on the

Aeroforce Interceptor, but I think I can generally forget about it.

That was actually one of the bigger worries for me honestly.

I will probably think of more later.

I was really fortunate to be invited down to the Off Road Expo show in Pamona, California by Milestar Tire to display the #LX45 in their booth. I was a really awesome experience overall, and another bucket list item to check off for me. I have to admit, I was very nervous to have thousands of people, including some BIG industry players look over my little garage build. In the end it went great. I actually got to work into the booth both days and interact with people asking questions about the build. Lots of people where very impressed that I drove it.....now some 1650 miles out to the show.

The return trip back home to Colorado brought the final total for the shakedown run to just over 2400 miles!

Overall, for a first run, I couldn't be happier.

Some more reflection and review of the build from my notes....

The suspension of this thing is a TOTALLY different league from the

flat fender. I hope you get to go for a ride in it to compare to your

TJ. The road manors are really good. It is easy to drive on the

highway at modern 70-80mph speeds with one hand on the wheel and it

doesn't require constant attention. It doesn't seem to wander. There

is no steering wheel shimmy or shake. It doesn't seem to need a front

sway bar. You can toss it around pretty good and exceed most posted

corner speed signs without any issues.

The spring rates seem to be good, even the rear end ( which I thought

was going to be too stiff ). The stance is just about what I would

want. For REALLY big trips with more gear I might even swap in the

taller rear springs. The other really nice thing....it doesn't seem to

bottom out, or at least I can't feel it. I can't tell when the front

foam bumpstops engage either, they just basically 'catch' the axle

without any noise or drama which is so nice. I didn't notice the rear

suspension bottom out either, and it doesn't even have the big foam

stops yet. I think the good shocks really help and probably the best

thing is a decent amount of uptravel. I ended up with ~6" in front and

5" on the rear suspension ( 10.6 front shock travel, 10.1 rear shock

travel ).

In the entire 2400 mile trip I only had one butt-pucker moment on the

road. I was passing a group of motor-homes on a 2-lane highway in the

four corners area. This is basically on the 'res' and the roads are

crap. I was going about 75-85mph during the pass and hit a section of

repaired road with big 'rollers' in the pavement. I think any vehicle

would have gotten tossed around a bit.....getting tossed around a bit

on 40s at 23psi is a bit interesting. It was the only time I

specifically remember needing both hands on the wheel and having to

'try' and drive it through the issue. I think the rollers where big

enough and spaced just right to act basically like big whoops. I'm not

saying I went airborne.....but that is what it felt like....

The tires don't rub.....much....on the body. The rear tires just KISS

the lower edge of the fender when it is twisted all the way up. The

inside of one tire rubs on the bed panel a little....but the other

doesn't. I think it has something to do with how the panhard allows

the suspension to articulate. The front tires don't rub anything that

I could detect lock to lock. This is also with the new wheels which

have a bit more backspacing than I originally built it with. I think

the original wheels would make things even better.

Off road I really like the suspension also. I didn't get to do much

spirited driving yet, the Rubicon isn't really like that, but what

little I did felt really nice. Using all OEM bushings in everything

seemed like a big plus. There isn't any squeaking or clunking in the

suspension as it articulates or hits bumps.

The only real downside to the suspension I have found is how exposed

the rear frame side lower control arms are. They get hit. You can

drive around them to a degree, but you still hit them. I should

probably get them plated in a layer of 1/8-3/16 material in the

critical area. That would be a good winter project.

The vehicle seems to WANT to climb things. I think it is a lot of

things coming together.....suspension geometry, weight bias, lower

overall weight, etc. Overall I really like the vehicle size and

wheelbase. It feels bigger than the flat fender, but not HUGE. I was

the only one in the group to make Soup Bowl on the Rubicon. That felt

really good, especially with no seat time.

Gearing. Overall I am pretty dang happy. I think it could be tweaked a

little, but I think it would be a trade off generally. High range is

really pretty good. It could be a touch lower I think, but I wouldn't

want to drastically change it....maybe something like 5.38 instead of

5.00 would be better on the highway, but honestly I am not sure. It

works pretty well. I do still want to try something like 6-7:1 gearing

in the axles on a build like this at some point, especially with the

6-10 speed transmissions. The new transmission tune feels even better.

I don't think higher gears in the axles would be what I want. I don't

think I would do 4.88s with 40+ tires and a 6L80E at this point. That

is kind of a shame actually, I think the 6L80e really needs about a

2.5-2.7 low range. 2:1 probably isn't deep enough unless you want to

try 6-7:1 in the axles. 3:1 is getting too low where I think the crawl

ratio is getting too short. For future builds this is an interesting

conundrum honestly. You can't get an atlas with 2.5 gearing. My low

range gearing feels REALLY good. It is low enough to have fine

control, but not so low it is pushing you through the brakes all the

time and taking all the magic out of the torque converter. It will be

interesting to get it into different terrain. I have a feeling for

climbs I have to bump, I am going to need to force the transmission to

be able to start in 2nd low. I am a pretty firm believer still,

especially after building this one, that the sweet spot for an

automatic ( with a proper amount of power ) is about 50-55:1 with a

40-42" tire. I am 54:1 in the Lexus. I do notice a bit of torque

'lean', or rather that the chassis is loaded up more, with more

upstream gearing vs downstream gearing. I am only running 4.10s in the

axles. For future builds, I would rather have more gearing in the

axles and less gearing in the transmission and t-case generally. I

think this calms the chassis down when doing dumb stuff. The Lexus

isn't bad, but I can feel it.

Steering. Overall I am happy, but it still needs some tweaking. The

steering wheel feels a bit heavy. I'm not sure if this is a pressue or

flow issue. The steering never seems to run out of force, it turns the

tires whenever you want, even with the tires aired down and the front

diff locked. It just feels a bit heavy. At speed with the engine rpms

up you don't notice it at all. The steering wheel feel on the road at

speed is actually very good. I really like that the steering doesn't

squeak at all. I might have to try some pump mods in the future. The

steering angle capability is also very nice. It turns lock to lock

with 40s. That makes the 112" wheelbase much more maneuverable than I

thought it would be. It is longer no doubt, but I didn't find myself

having to 3 point much if at all.

Lockers. The selectable lockers are ok. I left the center diff locked

99% of the time. I honestly didn't have to use the diff locks as much

as I thought I would. I did start to experiment more with different

combinations of locker use the 2nd day on the Rubicon. In one spot I

even tried a front 'dig' kinda thing to get the front end to slip

down, and that actually seemed to work pretty well. I basically kicked

out the center diff lock and grabbed the ebrake. That seemed to allow

me to force the vehicle to pull more with the front end and slip the

front axle sideways down off a big rock wall when trying to turn at

the same time. I also played with using the front or rear locker only

in mild situations. I still think that front locker only seems to work

better than rear locker only to me. Waiting for the lockers to engage

or disengage was kinda annoying, but it isn't bad. I have the locker

switch icon wired to the fork position switch on the elocker diff. I

can see exactly when the locker changes....and you can hear it click

typically. The toyota elockers actually work pretty well overall. They

seem to lock and unlock ok.

To muse about future builds. For a vehicle that is part time 4wd. I

would lean heavily toward running an automatic front locker with

selectable rear locker like the flatty. That combo just seems to work

better with less driver input required. Add in a t-case and front axle

that would hold up to front front digs. Add in rear left/right cutting

brakes and maybe another trick or two with the brakes. I think the

automatic front locker does a better job at locking and unlocking in

the medium stuff vs the driver having to turn the selectable locker on

and off. This is me just chasing unicorns to a degree. Both combos are

probably equally capable, its just preference about how the vehicle

handles the medium hard stuff.

Power. The 5.3 feels about right, but isn't a silly amount of power.

It is enough to be fun. It is enough to get up any hill on the highway

at extra legal speeds on 40s. That is about 325hp. That is honestly

pretty darn good. I'm not saying that I wouldn't give about 400hp a

try in the next one. I've driven the Summer Camp jeep with 525ish? It

was fun, but I think I got to 1/2 throttle maybe. In this build, I

wouldn't want much more on this chassis.....but I am happy I did a v8.

The low 1st gear in the 6l80e makes it feel like more and really helps

get things moving.

Cooling. I am VERY happy with how the cooling system worked out. I

haven't noticed any issues at all. It runs on thermostat and the

transmission doesn't heat up. I need to set the alarms on the

Aeroforce Interceptor, but I think I can generally forget about it.

That was actually one of the bigger worries for me honestly.

I will probably think of more later.

- Thread starter

- #720

@Mieser Can you tell me more about your foam bumpstops?

GM part number 15712438 I believe is the most current version. They are a nice big soft foam bumpstop that works VERY well for the price. They have been using them for about 10 years now I think? There is also now a Dorman made version if you don't want yellow.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)