Just replaced my CVs with CVJ axles, D/S went in without issue, snap ring on P/S seems a little too thick to slide in all the way, do they make these in slimmer thicknesses?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Axle snap ring doesn't fit? (1 Viewer)

- Thread starter indephenit

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?jLB

Another one followed me home. Can we keep it?

Maybe something like this would help?

cruiserteq.com

cruiserteq.com

Eeek! Maybe I’m seeing things, but those splines don’t look “great” to me. Were those axles just re-booted?

Are you trying to reuse the old snap ring? I thought that was a no-no…

Front Wheel Snap Ring Kit - Fits 1998-2007 IFS UZJ100/LX470

Toyota Land Cruiser Front Wheel Bearing Kits

Eeek! Maybe I’m seeing things, but those splines don’t look “great” to me. Were those axles just re-booted?

Are you trying to reuse the old snap ring? I thought that was a no-no…

Last edited:

Fj80oregon

GOLD Star

Have you tried pulling the shaft back towards you a bit so it slides out some to clear the ring.

- Thread starter

- #4

They're from CVJ:Maybe something like this would help?

Front Wheel Snap Ring Kit - Fits 1998-2007 IFS UZJ100/LX470

Toyota Land Cruiser Front Wheel Bearing Kitscruiserteq.com

Eeek! Maybe I’m seeing things, but those splines don’t look “great” to me. Were those axles just re-booted?

9534 Archives - CVJ Axles

www.cvjreman.com

www.cvjreman.com

I had previously bought Cardone Axles that the hub flanges wouldn't slide over so I bit the bullet and bought a set of these, they were fine out of the box, camera on my phone just might be a bit of a potato

- Thread starter

- #5

oh yes, tugged and tugged, its in as far as it wants to go without the use of a hammerHave you tried pulling the shaft back towards you a bit so it slides out some to clear the ring.

jLB

Another one followed me home. Can we keep it?

Another thing that might make life easier

forum.ih8mud.com

forum.ih8mud.com

For Sale - 100 Series CV Axle Puller Tool

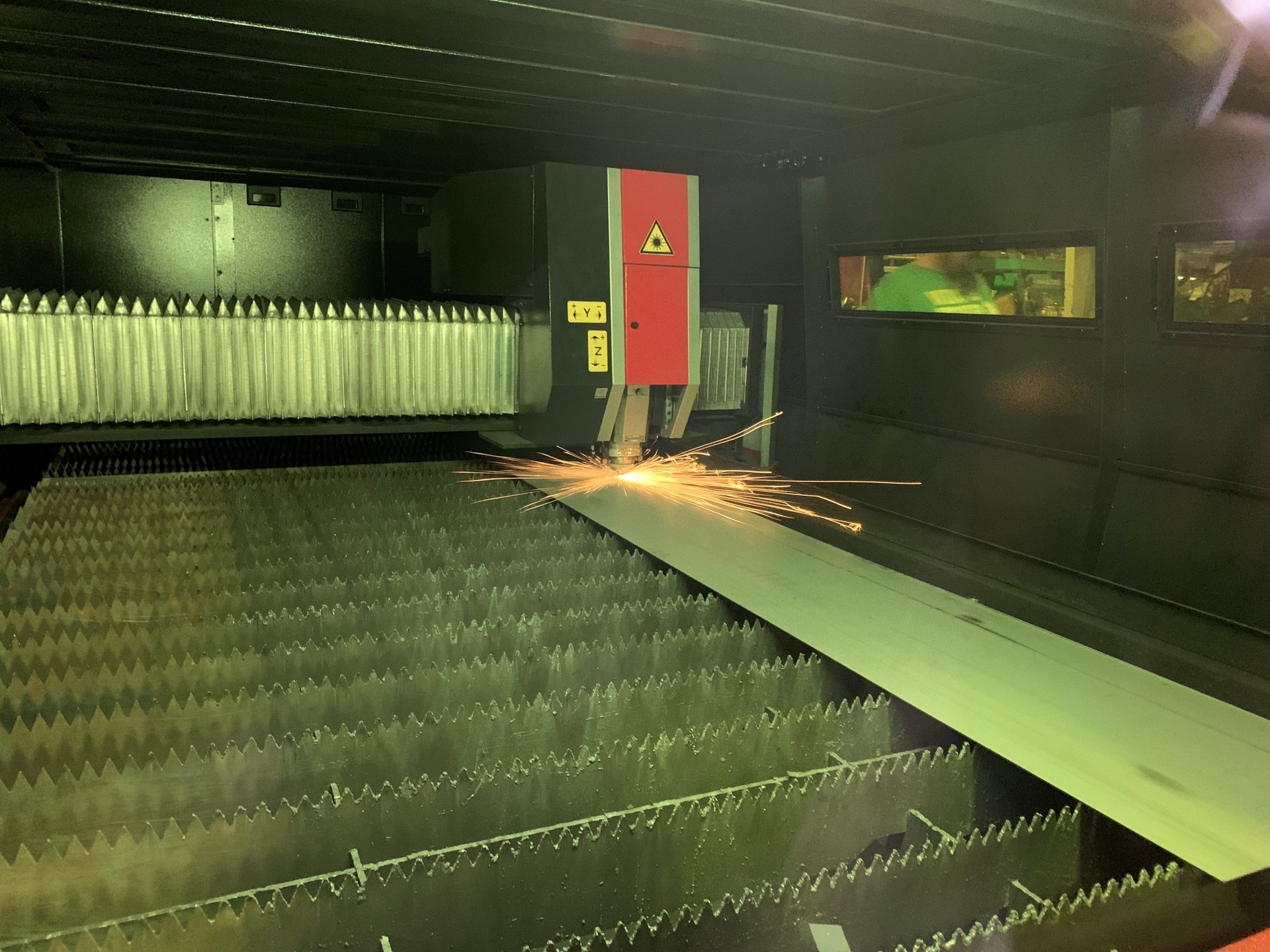

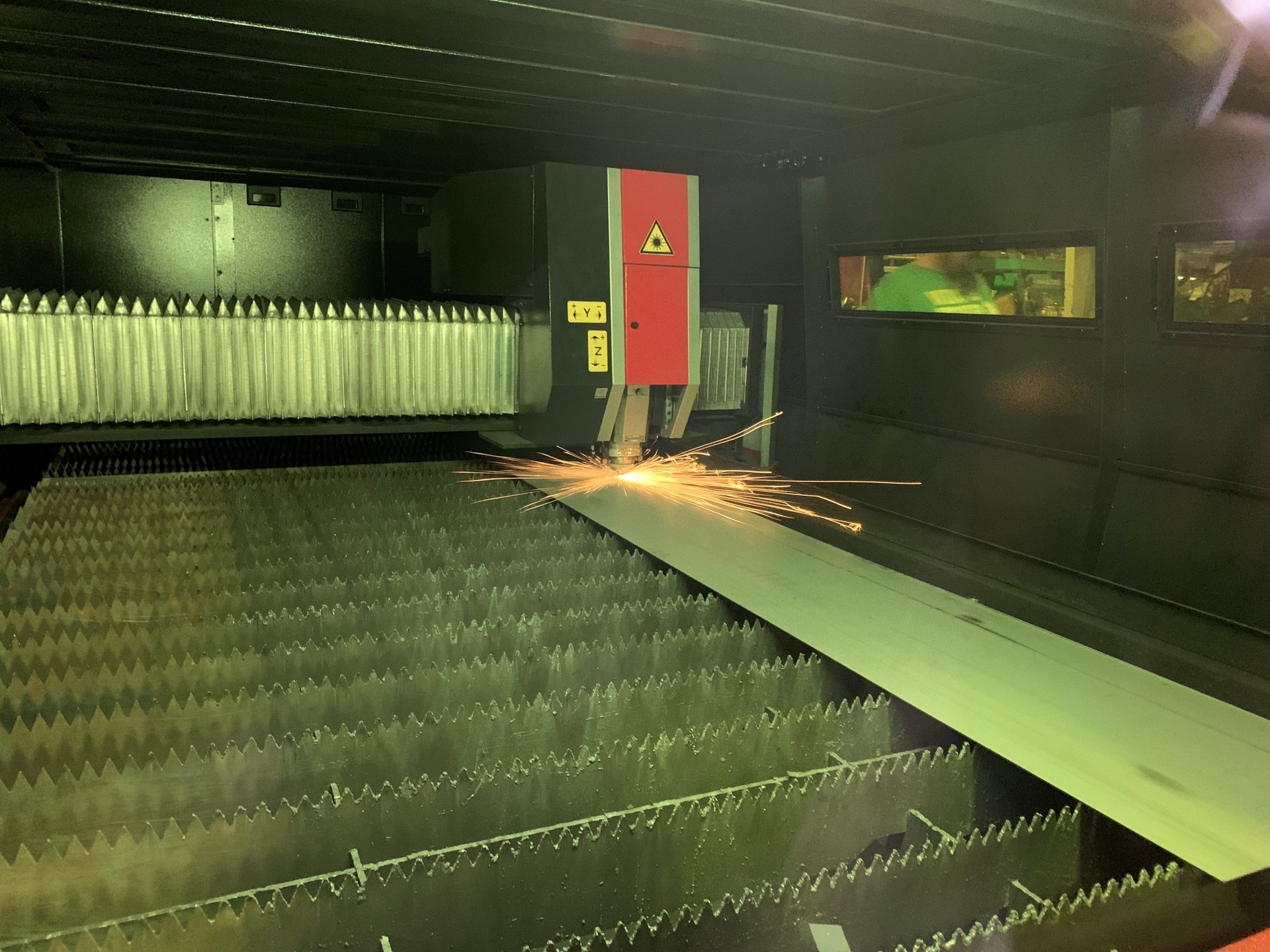

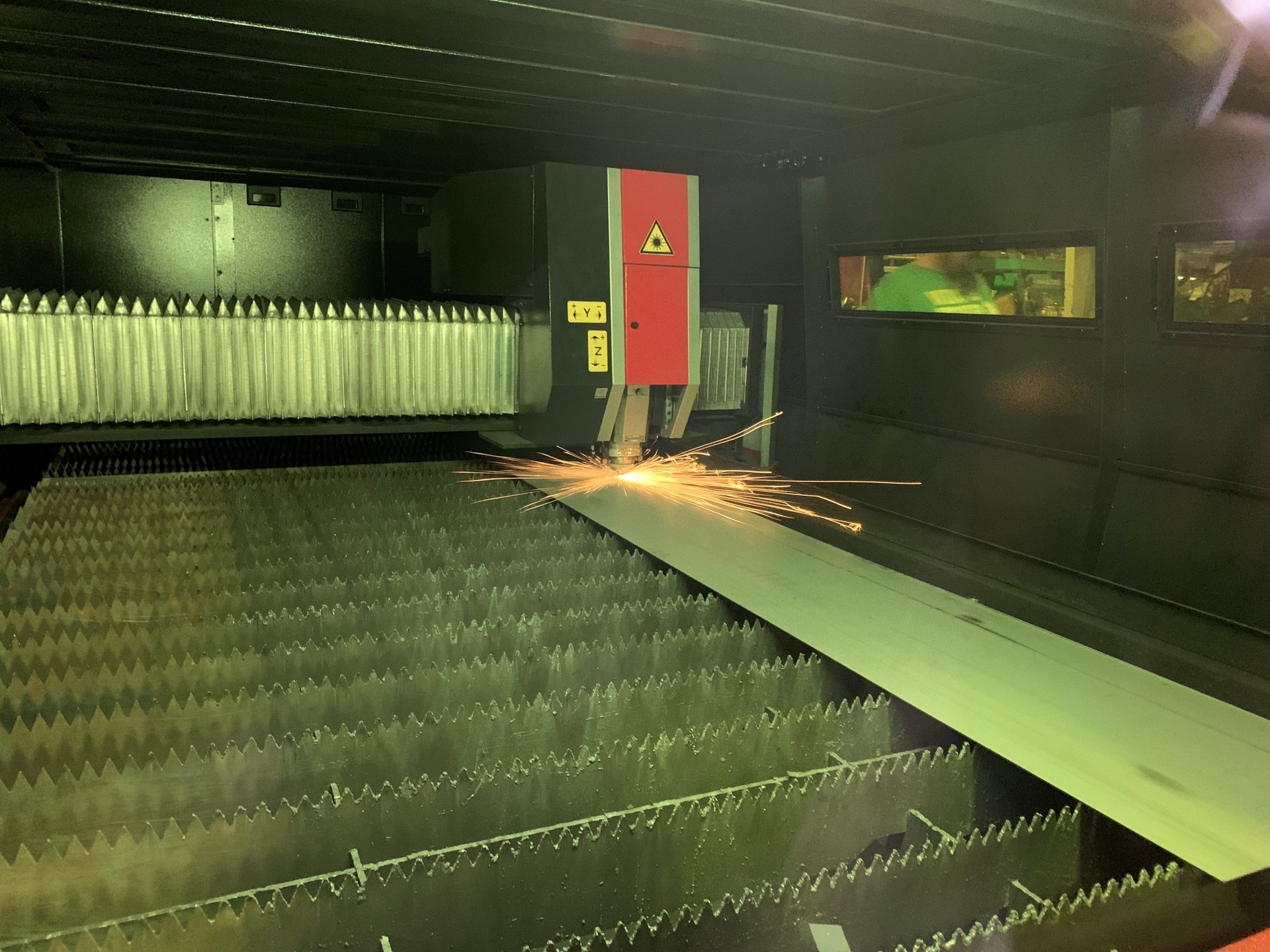

I created this tool to help pull the CV axle of your 100 Series LC/LX470 as far outward as possible to aid in measuring & installing a properly sized snap ring. This tool is made from 16ga. 14ga galvanneal 304-4 stainless steel drilled and reamed on a manual vertical mill laser cut on an Amada...

forum.ih8mud.com

forum.ih8mud.com

JunkCrzr89

Competent Ignoramoose

You need one of theseAnother thing that might make life easier

For Sale - 100 Series CV Axle Puller Tool

I created this tool to help pull the CV axle of your 100 Series LC/LX470 as far outward as possible to aid in measuring & installing a properly sized snap ring. This tool is made from 16ga. 14ga galvanneal 304-4 stainless steel drilled and reamed on a manual vertical mill laser cut on an Amada...forum.ih8mud.com

Yes, and the snap ring is supposed to be replaced with a new one of proper thickness pretty much every time one is removed, because they never return to their original inner diameter again.do they make these in slimmer thicknesses?

I agree, and yes, CVJs are just overly and unwarrantedly expensive reboots. Most of them have trashed outboard splines and are no better than what you’d get at a junkyard.Eeek! Maybe I’m seeing things, but those splines don’t look “great” to me. Were those axles just re-booted?

hoser

SILVER Star

T= is thickness. I just buy an assortment.

| 43420E | RING, SNAP (FOR FRONT DRIVE SHAFT) | ||

| 90520-31005 | T=2.8 | ||

| 90520-31006 | T=2.6 | ||

| 90520-31007 | T=2.4 | ||

| 90520-31008 | T=2.2 | ||

| 90520-31009 | T=2.0 | ||

| 90520-31010 | T=1.8 |

Are you trying to reuse the old snap ring? Please D O N T. These stretch when removing and can later fall off if reinstalled- creating much more troubles for ya. Hopefully you also used a new locking tab washer as well.

The snap ring puller tool helps but not necessary- you can make a puller to get it done in a pinch. But you do need an assortment of snap rings so that you can fit the right gap. No option but OEM- and as posted before Cruiser outfitters sells an assorted kit.

But I suggest reading the FSM to measure snapring gap so you ensure correct fit otherwise you cause wear to axle stub, washers and bearings.

The snap ring puller tool helps but not necessary- you can make a puller to get it done in a pinch. But you do need an assortment of snap rings so that you can fit the right gap. No option but OEM- and as posted before Cruiser outfitters sells an assorted kit.

But I suggest reading the FSM to measure snapring gap so you ensure correct fit otherwise you cause wear to axle stub, washers and bearings.

- Thread starter

- #10

Just gave this method a go with some scrap I had laying about. It was out as far as it was originally, looks like I'm going to have to get the correct thickness snap ring, I can't find my feeler gauge or calipers anywhere to confirm but the old snap ring didn't want to go.Another thing that might make life easier

For Sale - 100 Series CV Axle Puller Tool

I created this tool to help pull the CV axle of your 100 Series LC/LX470 as far outward as possible to aid in measuring & installing a properly sized snap ring. This tool is made from 16ga. 14ga galvanneal 304-4 stainless steel drilled and reamed on a manual vertical mill laser cut on an Amada...forum.ih8mud.com

jLB

Another one followed me home. Can we keep it?

the old snap ring didn't want to go.

This is probably a “good thing”, as it lessens the chance of a future “bad transfer case” post, when the used snap ring pops off, while driving down the road.

Are you trying to reuse the old snap ring? Please D O N T. These stretch when removing and can later fall off if reinstalled- creating much more troubles for ya. Hopefully you also used a new locking tab washer as well.

The snap ring puller tool helps but not necessary- you can make a puller to get it done in a pinch. But you do need an assortment of snap rings so that you can fit the right gap. No option but OEM- and as posted before Cruiser outfitters sells an assorted kit.

But I suggest reading the FSM to measure snapring gap so you ensure correct fit otherwise you cause wear to axle stub, washers and bearings.

Yup

Front Wheel Snap Ring Kit - Fits 1998-2007 IFS UZJ100/LX470

Toyota Land Cruiser Front Wheel Bearing Kits

You can pull by hand, but doesn't settled grease between brass bushing and outer axle of FDS (AKA CV) as well. You can also put a temporary snap ring on, and drive around the block. Then come back, with wheels on the ground. Which helps push FDS axle outward. Then pull by hand and place on the very thickest "new" snap ring. Making sure gap between hub flange and snap ring less than 0,20 MM.

Tool for pulling made (first made) with just lying around the shop

It also best to put a new grease cap on. Cap must be very very tight, to keep water out.

Or you'll likely see brown grease, which indicates water contamination next service.

Last edited:

i made myself this little tool that pulls the CV axle out, you might want to make something like this ...

I'm in the middle of the same job and have been thinking about how to pull the axle to fit the snap ring, so this timely! This is a slick trick if the right hardware is laying around. Would a freebie auto parts store rental axle puller do the same?

FYI, on this other thread 2001LC posted the FSM instructions on selecting the right snap ring, in case you haven't found it already. (edit - didn't notice he already posted this info above, my bad)

forum.ih8mud.com

forum.ih8mud.com

The mom and pop shop that did the rotors on my LC for the PO definitely appeared to reuse the snap ring, as well as the star lock washers, rusty cone washers, and somehow mashing the cr@p out of axle nuts. Needless to say I wasn't thrilled to see it, but at least I know it will be back together correctly. Just a word of warning for folks, if you have some indy shop (that doesn't specialize in LCs) do rotors or bearings, you might want to pop the dust cap and see if you need to put in a new snap ring given the advice above. x2 with the dust cap as noted above. They reused the dust caps and I had the brown grease like in the picture.

FYI, on this other thread 2001LC posted the FSM instructions on selecting the right snap ring, in case you haven't found it already. (edit - didn't notice he already posted this info above, my bad)

Replace These Wheel Bearings?

I used the following torque specs on a LN 106 Hilux front axle (Cruiser also has the same front hub setup) and it worked at the first time. See at 4:00 minute mark here

forum.ih8mud.com

forum.ih8mud.com

The mom and pop shop that did the rotors on my LC for the PO definitely appeared to reuse the snap ring, as well as the star lock washers, rusty cone washers, and somehow mashing the cr@p out of axle nuts. Needless to say I wasn't thrilled to see it, but at least I know it will be back together correctly. Just a word of warning for folks, if you have some indy shop (that doesn't specialize in LCs) do rotors or bearings, you might want to pop the dust cap and see if you need to put in a new snap ring given the advice above. x2 with the dust cap as noted above. They reused the dust caps and I had the brown grease like in the picture.

JunkCrzr89

Competent Ignoramoose

M8 x 1.25, if I recall correctly.What is the diameter and thread pitch on the bolt into the axle?

Eyedaho

SILVER Star

The "axle nuts" can get dorked if a shop doesn't have a 54mm socket, and instead uses a cold chisel to spin the nuts.I'm in the middle of the same job and have been thinking about how to pull the axle to fit the snap ring, so this timely! This is a slick trick if the right hardware is laying around. Would a freebie auto parts store rental axle puller do the same?

FYI, on this other thread 2001LC posted the FSM instructions on selecting the right snap ring, in case you haven't found it already. (edit - didn't notice he already posted this info above, my bad)

Replace These Wheel Bearings?

I used the following torque specs on a LN 106 Hilux front axle (Cruiser also has the same front hub setup) and it worked at the first time. See at 4:00 minute mark hereforum.ih8mud.com

The mom and pop shop that did the rotors on my LC for the PO definitely appeared to reuse the snap ring, as well as the star lock washers, rusty cone washers, and somehow mashing the cr@p out of axle nuts. Needless to say I wasn't thrilled to see it, but at least I know it will be back together correctly. Just a word of warning for folks, if you have some indy shop (that doesn't specialize in LCs) do rotors or bearings, you might want to pop the dust cap and see if you need to put in a new snap ring given the advice above. x2 with the dust cap as noted above. They reused the dust caps and I had the brown grease like in the picture.

That's gotta be it for sure. Total hack job. Looks like they even cut a notch in the outer nut to assist. I'm sure they dialed in the preload perfectly hammering with their chisel. That would explain why my bearings were spinning on the spindle.The "axle nuts" can get dorked if a shop doesn't have a 54mm socket, and instead uses a cold chisel to spin the nuts.

Mine were dorked when I bought it.. and they had been repacked multiple times by the Lexus dealer lol they were in great shape, but I still found it surprising nonetheless.The "axle nuts" can get dorked if a shop doesn't have a 54mm socket, and instead uses a cold chisel to spin the nuts.

Also FWIW, my driver side was too tight for the snap rings in the kit from Cruiser Outfitters at first too. I just filed down the old one and drove it down the road a few miles and it settled in and I was able to use one of the new ones.

Last edited:

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)