I was going to post this into my existing vortec swap, but figured this is probably something worthy of it's own thread.

I am running a 2006 vortec 5.3l drive-by-wire motor. Drive by wire means there is no mechanical connection with the throttle and pedal. It's all done electronically. While super cool in design, swapping this style of engine into a vehicle that did not have DBW can present some challenges.

It is made more difficult because the 2003 and later vortec motors, when they went to DBW, also started using something called a serial data connection that marries the internal cab controls (ie radio, a/c, cruise control, ect) to the PCM through another computer called a body control module (or BCM).

The cruise control isn't a big deal to me right now, but a/c is. I do have a working a/c after getting custom hoses made up and wiring the vortec compressor up to the stock toyota a/c system. Essentially the toyota a/c amplifier controls the vortec compressor just like it would if the stock 1FZ were still there.

There's one big problem though - there is no idle compensation when the a/c is requested. Basically the compressor kicks in and the motor has to self compensate from the load added by the compressor. What you get is a really low idle speed and poor a/c performance at idle, and weird shifting when slowing to a stop if the compressor should turn on or off as the transmission downshifts.

Several people I contacted said there's no fix. The serial connection won't accept just a straight 12v signal to tell the pcm the a/c is requested.

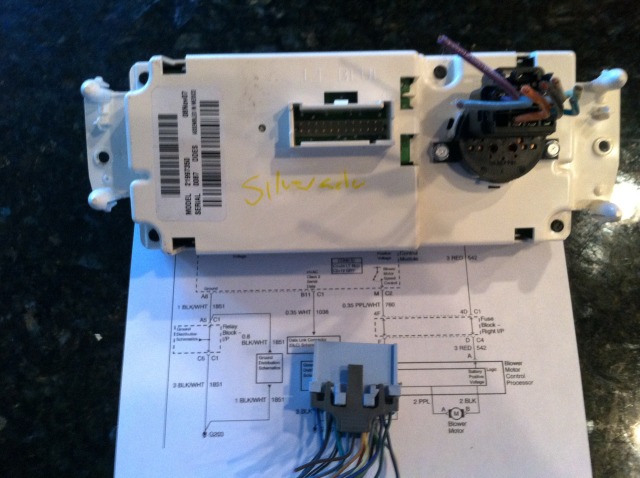

However, there is a fix. Someone on the LS1tech forum posted a nugget of information on how he used the a/c control head from a 2003 or later truck and uses it to send the serial data request to the pcm to activate the a/c.

I am waiting a used control head to show up - I bought one from ebay.

The plan is to use a control head from a later model silverado to get the serial input needed. This will be done by running a constant 12v wire for keep alive, connecting the toyota a/c amp output that activates the compressor to the keyed input on the silverado head, and also adding a signal to the a/c low pressure input to tell the silverado head that the system is charged with freon. Finally, the last connection will be to the serial data wire - it's the same wire that connects to a scanner.

Serial data works by sending binary codes through this signal wire. Any component (pcm, BCM, a/c control, ect) in this circuit has it's unique code and will respond to each other when called by it's own binary code.

Sounds complex - no?

The key part to this is the integration of the silverado a/c head unit - it's going to be perma-mounted under the dash. It will remember it's last known setting as long as it has a constant 12v power to it. So, if you push the a/c request button on it, it will keep the a/c requested on even after the engine is shut down. The keyed portion will be how the toyota a/c amp will activate the serial request. The pcm will see that the silverado a/c head is powered on and that the a/c switch is on, and will then automatically idle the motor up a little and then kick on the compressor - all in sweet harmony.

More to follow once I get the a/c head I bought.

I am running a 2006 vortec 5.3l drive-by-wire motor. Drive by wire means there is no mechanical connection with the throttle and pedal. It's all done electronically. While super cool in design, swapping this style of engine into a vehicle that did not have DBW can present some challenges.

It is made more difficult because the 2003 and later vortec motors, when they went to DBW, also started using something called a serial data connection that marries the internal cab controls (ie radio, a/c, cruise control, ect) to the PCM through another computer called a body control module (or BCM).

The cruise control isn't a big deal to me right now, but a/c is. I do have a working a/c after getting custom hoses made up and wiring the vortec compressor up to the stock toyota a/c system. Essentially the toyota a/c amplifier controls the vortec compressor just like it would if the stock 1FZ were still there.

There's one big problem though - there is no idle compensation when the a/c is requested. Basically the compressor kicks in and the motor has to self compensate from the load added by the compressor. What you get is a really low idle speed and poor a/c performance at idle, and weird shifting when slowing to a stop if the compressor should turn on or off as the transmission downshifts.

Several people I contacted said there's no fix. The serial connection won't accept just a straight 12v signal to tell the pcm the a/c is requested.

However, there is a fix. Someone on the LS1tech forum posted a nugget of information on how he used the a/c control head from a 2003 or later truck and uses it to send the serial data request to the pcm to activate the a/c.

I am waiting a used control head to show up - I bought one from ebay.

The plan is to use a control head from a later model silverado to get the serial input needed. This will be done by running a constant 12v wire for keep alive, connecting the toyota a/c amp output that activates the compressor to the keyed input on the silverado head, and also adding a signal to the a/c low pressure input to tell the silverado head that the system is charged with freon. Finally, the last connection will be to the serial data wire - it's the same wire that connects to a scanner.

Serial data works by sending binary codes through this signal wire. Any component (pcm, BCM, a/c control, ect) in this circuit has it's unique code and will respond to each other when called by it's own binary code.

Sounds complex - no?

The key part to this is the integration of the silverado a/c head unit - it's going to be perma-mounted under the dash. It will remember it's last known setting as long as it has a constant 12v power to it. So, if you push the a/c request button on it, it will keep the a/c requested on even after the engine is shut down. The keyed portion will be how the toyota a/c amp will activate the serial request. The pcm will see that the silverado a/c head is powered on and that the a/c switch is on, and will then automatically idle the motor up a little and then kick on the compressor - all in sweet harmony.

More to follow once I get the a/c head I bought.

Last edited: