BigHighBlue

GOLD Star

Build looks great! I'm in the process of returning my carb to OEM from a weber and need some help. I see your hard fuel supply line, do you have a return as well? The weber that was on mine didn't have a return but here is a plugged return going back to the tank. Not sure what the best option will be but the carb arrives next week at which point I'll know what I'm working with. Mines a Dec '78 so may be different. Cheers!My dog Otis was hit by a car a few weeks ago and I have really been beating myself up about it. I am going spend a little more time with the family and a little less time working on old cars.

Opportunity cost:

I decided to skip the fun of learning how to rebuild a carburetor and just left it to the professionals. I called Mark's Off-Road Enterprises and a few days later I had a fully rebuilt and upgraded carburetor. It appears to be very well done. Mark even laser cuts an "M" into the sight glass cover so you know he is serious. Tonight I will replace the fuel lines and filter and see if she runs.

View attachment 2108044

View attachment 2108046

View attachment 2108047

View attachment 2108051

Easy!

View attachment 2108052

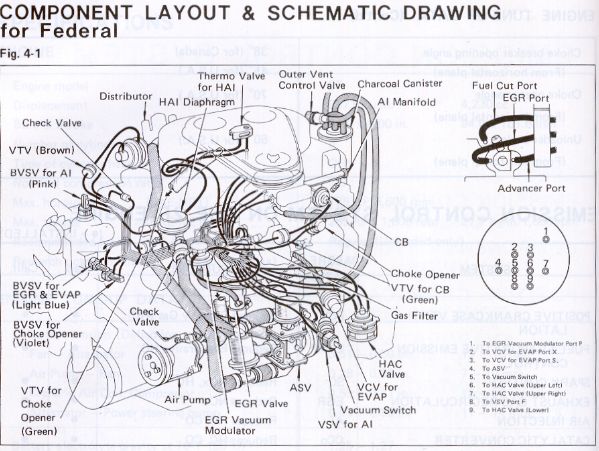

Thanks for the great documentation of this. For my 3/79 I have been researching and considering a desmog. My Desmog Thread over in the 60 section is a good resource for 79-80 desmog technical info. Jim C provides most of the expert level input on that thread. I personally would recommend not deleting the CB, Evap or PCV considering they aren’t failure prone and keep the fumes down. I also have a well functioning HAC system and continually venture between sea level and 5000 ft so I would probably keep it too. I’m super interested in how you fabricate plugs for the exhaust flapper valve holes. I will be doing that sooner or later on both my 40s.

Thanks for the great documentation of this. For my 3/79 I have been researching and considering a desmog. My Desmog Thread over in the 60 section is a good resource for 79-80 desmog technical info. Jim C provides most of the expert level input on that thread. I personally would recommend not deleting the CB, Evap or PCV considering they aren’t failure prone and keep the fumes down. I also have a well functioning HAC system and continually venture between sea level and 5000 ft so I would probably keep it too. I’m super interested in how you fabricate plugs for the exhaust flapper valve holes. I will be doing that sooner or later on both my 40s.