Alright, so now that the snow has finally melted and and I can see my trailer, I want to pull the F, transmission, and transfer case from my 68. I did some searches but haven't found what I'm looking for.

(I am having some dejavu right now... maybe I already posted this somewhere? Sorry).

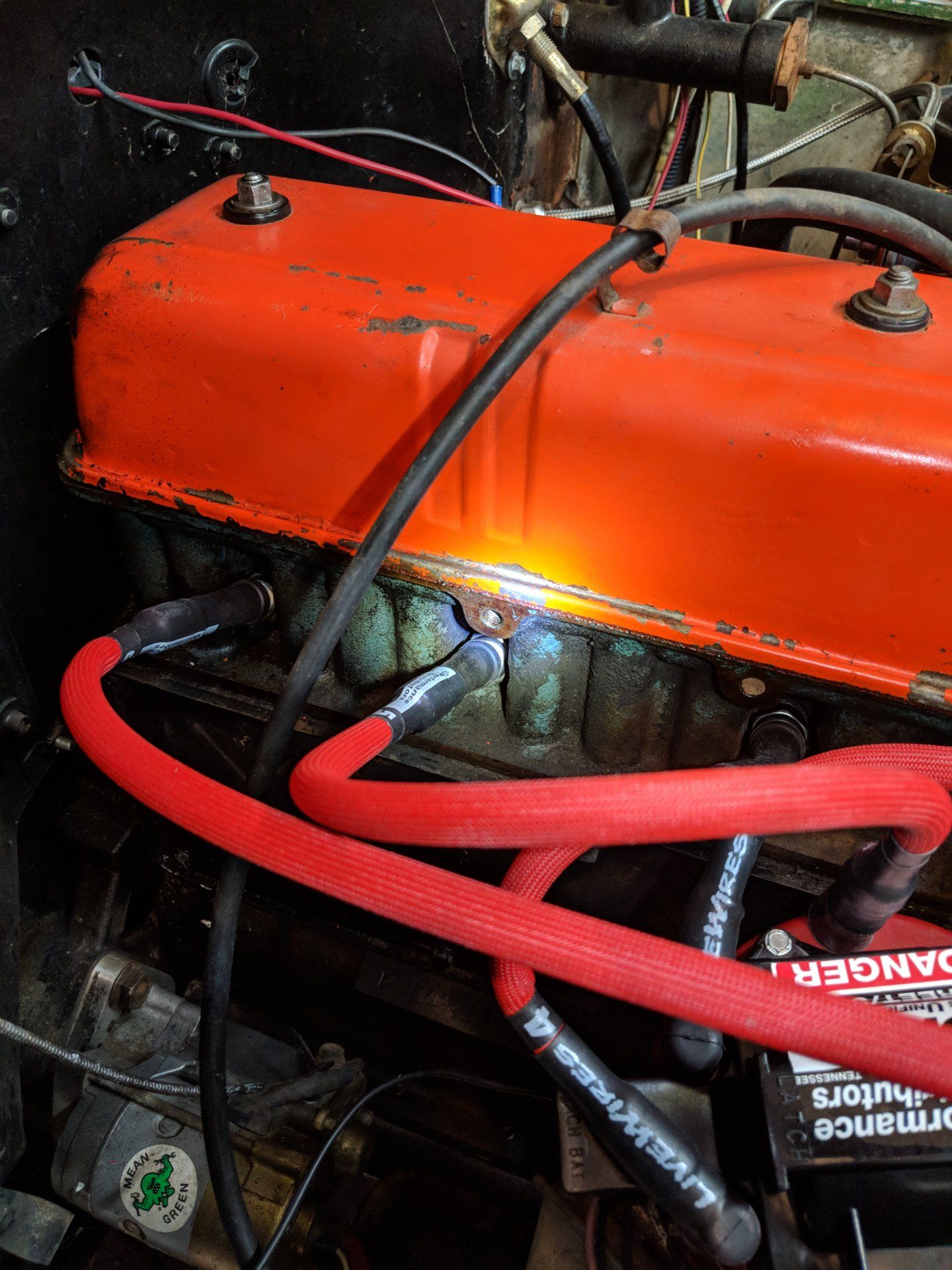

Will any of you please share your opinions on where to bolt the chains to get the engine out of the chassis? I will be removing the front sheet metal to make it easier, I just need to know the best place to bolt the chain to the block.

One post said the head bolts, but I'd like to keep the engine intact if possible. I'll also be using these mount points to install the freshly rebuilt, assembled, and painted 2F later in April, so I don't want to crack the seal on the valve cover and head to get the engine installed.

Another post suggested using the alternator bracket bolt and intake manifold (or maybe it was exhaust manifold) bolt on the diagonal to the alternator bolt. Is this safe? I'll be exerting upward force on horizontal bolts...

Also, will you please tell me the correct thread and size bolt to use for whatever mount you recommend?

(I am having some dejavu right now... maybe I already posted this somewhere? Sorry).

Will any of you please share your opinions on where to bolt the chains to get the engine out of the chassis? I will be removing the front sheet metal to make it easier, I just need to know the best place to bolt the chain to the block.

One post said the head bolts, but I'd like to keep the engine intact if possible. I'll also be using these mount points to install the freshly rebuilt, assembled, and painted 2F later in April, so I don't want to crack the seal on the valve cover and head to get the engine installed.

Another post suggested using the alternator bracket bolt and intake manifold (or maybe it was exhaust manifold) bolt on the diagonal to the alternator bolt. Is this safe? I'll be exerting upward force on horizontal bolts...

Also, will you please tell me the correct thread and size bolt to use for whatever mount you recommend?

Last edited: