Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This came with my China winch (3 Viewers)

- Thread starter aktundra

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Maybe magnets for the remote to stick to the bumper? Just guessing

Circuit breaker maybe.

Yup, a cheap a$$ circuit breaker. Definitely test is hard before you rely on it, or at least be ready to bypass it if need be.

Eyedaho

SILVER Star

More specifically three cheap ass circuit breakers in parallel for a higher current draw. Super sketch.Yup, a cheap a$$ circuit breaker. Definitely test is hard before you rely on it, or at least be ready to bypass it if need be.

My buddy had what looks identical to that one on his rig...it kept cutting out on easy pulls. He ditched the POS breaker and has been good since.

Still a good idea to have some protection. I use the Littelfuse JLLN 150 in holders on the positive side of both battery circuits that feed the winch through a Blue Sea switch. Can't remember how I calculated this, but I have spare 200 amp fuses in case I came in a little low on capacity for a hard pull. Never failed me, but can honestly say the winch has never been loaded down near it's capacity yet.

MrMikeyG

SILVER Star

These come with the Harbor freight badlands zxr series winches as well. I found mine to be a slight pain to fit. Can anyone post a picture of a nicer/better option?

I think the one the OP posted is designed to blow 1 section at a time right?

I think the one the OP posted is designed to blow 1 section at a time right?

Eyedaho

SILVER Star

Since it's wired in parallel, the current will be split between the three circuit breakers under ideal conditions. It's a cheaper way to get a higher current circuit breaker versus using one breaker of the correct higher amperage rating. In practice there will be some difference in current between the three due to variation in resistance. When the circuit is overloaded, whichever breaker is the first to have a load higher than it's tripping current will trip. Then all of the current will be split between the other two, and the next one will trip, then the last one. Ideally that should happen instantaneously. I would expect it to possibly trip more often than a properly sized single circuit breaker, since it adds two extra breakers and there will be more variation in current loads across the three legs versus one. It might be an ok setup, and maybe someone more knowledgeable will weigh in. Using a cheaper circuit protection device that isn't as robust is not my first choice, but I tend to think in worst case terms with things like that.These come with the Harbor freight badlands zxr series winches as well. I found mine to be a slight pain to fit. Can anyone post a picture of a nicer/better option?

I think the one the OP posted is designed to blow 1 section at a time right?

Last edited:

Azca

If there is a harder way - I will find it...

It is an overload device, breaker is the best way to describe it. No way to reset, it will open once it reaches a pre-determined temp. Once it cools, it will reset, maybe... Trash it, get a set of fuses as greentruck stated. Fuses are far superior for protecting equipment when compared to breakers. I have mine mounted on fuse blocks on the back of the battery box (with covers) but will be moving them when I finally get around to installing the dual battery set up I have sitting in the garage. Just remember, carry spares!

maxamillion2345

Franken-80

These are the fuseholders I use with the Littelfuse 150 A fuses. The #1 feed from the primary battery is buried down below the oil jug stash in front of the battery on US-spec trucks.

The #2 feed fuse is easier to see. It's perched on the right fender arch near the Blue Sea switch that both these are controlled by, which sits right behind the AUX battery.

A close-up with the cover on.

And the bare-naked fuse in its holder.

I used welding cable for all the big connections. Yes, the sheathing is soft, but you apply looming of some sort to protect it and the doubling of the insulation and the looming is pretty good against most causes of damage to cables. And you should almost always upgrade your cables from whatever the winch mfg provides as it is almost always inadequate for serious winching.

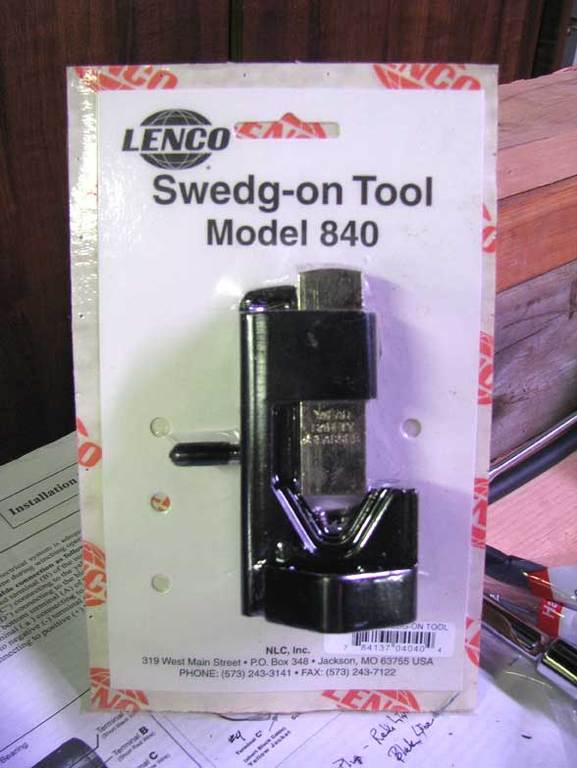

You'll need lugs suitable for your purposes and connection. This tool is handy and inexpensive.

The #2 feed fuse is easier to see. It's perched on the right fender arch near the Blue Sea switch that both these are controlled by, which sits right behind the AUX battery.

A close-up with the cover on.

And the bare-naked fuse in its holder.

I used welding cable for all the big connections. Yes, the sheathing is soft, but you apply looming of some sort to protect it and the doubling of the insulation and the looming is pretty good against most causes of damage to cables. And you should almost always upgrade your cables from whatever the winch mfg provides as it is almost always inadequate for serious winching.

You'll need lugs suitable for your purposes and connection. This tool is handy and inexpensive.

ChaseTruck

--

I've used that breaker on our HF12k setup in the '93. Hasn't given me any trouble; recently pulled an F150 out of the drink, ~180 feet out, slow bottom layer pull, needed to re-spool the line, but the breaker certainly held. I did wrap that breaker setup in heat shrink insulation because I didn't like having such a large area that's battery-positive exposed and open under the hood. My winch cable is long enough to reach the positive pole on the battery just in case. When I set up the 1/0 cables for that winch I used that wedge/hammer thing to install the lugs; by now I have an Amazon-sourced hydraulic crimper that I like much better. And as for the fuses, I'm never sure how those work or how to read the ratings when they're used with a winch where the current draw can easily exceed 400A. But maybe I'm reading the winch specs wrong, as well.

Azca

If there is a harder way - I will find it...

Be careful with this. The heat shrink, as it compresses the components, can cause the internal mechanical mechanisms to bind and not allow them to operate properly.I've used that breaker on our HF12k setup in the '93. Hasn't given me any trouble; recently pulled an F150 out of the drink, ~180 feet out, slow bottom layer pull, needed to re-spool the line, but the breaker certainly held. I did wrap that breaker setup in heat shrink insulation because I didn't like having such a large area that's battery-positive exposed and open under the hood. My winch cable is long enough to reach the positive pole on the battery just in case. When I set up the 1/0 cables for that winch I used that wedge/hammer thing to install the lugs; by now I have an Amazon-sourced hydraulic crimper that I like much better. And as for the fuses, I'm never sure how those work or how to read the ratings when they're used with a winch where the current draw can easily exceed 400A. But maybe I'm reading the winch specs wrong, as well.

Had this issue with a bunch of exit lights on a project I was running as an electrician years ago. The local fire code required that all exit lights had to have a flashing function while in emergency mode. I had the inspector come in for a final and he had to turn down the installation as some of them were not working. Funny part is that we could have sworn they were working earlier. Once he left I pulled down several of the units to find that the heat shrink applied by the manufacturer was causing the contacts to hold open on the ice cube relays.

I absolutely agree with you on the extra exposed area, definitely not desirable.

One item, just because the devices did not open does not mean that they are functional. I don't trust breakers (mechanical devices) in harsh environments. I still recomend going the fuse route, time tested and proven.

ChaseTruck

--

Thanks for the heads-up. I don't think the heat shrink is on ultra tight.Be careful with this. The heat shrink, as it compresses the components, can cause the internal mechanical mechanisms to bind and not allow them to operate properly.

Had this issue with a bunch of exit lights on a project I was running as an electrician years ago. The local fire code required that all exit lights had to have a flashing function while in emergency mode. I had the inspector come in for a final and he had to turn down the installation as some of them were not working. Funny part is that we could have sworn they were working earlier. Once he left I pulled down several of the units to find that the heat shrink applied by the manufacturer was causing the contacts to hold open on the ice cube relays.

I absolutely agree with you on the extra exposed area, definitely not desirable.

One item, just because the devices did not open does not mean that they are functional. I don't trust breakers (mechanical devices) in harsh environments. I still recomend going the fuse route, time tested and proven.

I wouldn't mind going the fuse route. I haven't found anything that would support the current draws from a winch, but I have to admit that I haven't looked very hard. IIRC the fuses I found were in the 150A range, and to me that didn't jive with the current draw of the winch under a heavy load. Then again, I think that breaker thing is rated ~240A (3 x 80A). Perhaps I don't understand peak vs sustained current with winches. If someone can point me to a fuse system that'll handle 400+ Amps I'd be all ears.

Thanks for the heads-up. I don't think the heat shrink is on ultra tight.

I wouldn't mind going the fuse route. I haven't found anything that would support the current draws from a winch, but I have to admit that I haven't looked very hard. IIRC the fuses I found were in the 150A range, and to me that didn't jive with the current draw of the winch under a heavy load. Then again, I think that breaker thing is rated ~240A (3 x 80A). Perhaps I don't understand peak vs sustained current with winches. If someone can point me to a fuse system that'll handle 400+ Amps I'd be all ears.

I don't recall my exact thinking when I came up with my system (fuses pictured above), but I think it went something like this. A light to medium pull is likely well within the 150 A limit of the fuse on one battery's circuit. For heavier pulls, I can draw from both batteries, so 300 A should be possible. Blow one or both of those and replace with the 200 A fuses and you get to 400 A. This does mean that you're putting both batteries into the fray, instead of holding one in reserve. I tend to think I won't blow up both batteries at once, but I rather hope I never need to test this theory.

Eyedaho

SILVER Star

Make sure that you're sizing a fuse to protect your wire, versus what your winch is rated for. 400A+ is for a big cable, like 4/0. Keep in mind too that most fuses that you'll be looking at can withstand short current spikes well above their current rating. Look for ones that are longer blow, like Mega, to be able to better handle momentary loads. This chart has some good info on how to size your wire and fuse:Thanks for the heads-up. I don't think the heat shrink is on ultra tight.

I wouldn't mind going the fuse route. I haven't found anything that would support the current draws from a winch, but I have to admit that I haven't looked very hard. IIRC the fuses I found were in the 150A range, and to me that didn't jive with the current draw of the winch under a heavy load. Then again, I think that breaker thing is rated ~240A (3 x 80A). Perhaps I don't understand peak vs sustained current with winches. If someone can point me to a fuse system that'll handle 400+ Amps I'd be all ears.

Make sure that you're sizing a fuse to protect your wire, versus what your winch is rated for. 400A+ is for a big cable, like 4/0.

SNIP

Yeah, that's a start is all I was offering. I'm running Hobart Size 2 cable which is more or less 2/0. There would only be 400 A on the lead from the Blue Sea combiner switch to the winch terminal - and that would be a Black Swan event for me if I ever could get that stuck to need that kind of juice. But yeah, do your due diligence when you install a winch. I'd bet that more than half of all installs are probably without any protection at all other than the wires melting down.

Here's a link to the info on the fuses I'm using.

JLLN150 - JLLN Series - Class T Fuses Industrial Power Fuses - Littelfuse

They are probably a little on the fast acting side for using them with a winch. I figure that's the safest thing until I get more experience working with loads that push them to their limits. I don't think I've been close yet.

Users who are viewing this thread

Total: 4 (members: 0, guests: 4)