Now that's a damn good idea ...

Yes it is... I have 2 decent jackstands that I've used for a couple of years w/o any problems... But I could use about 2-3 more...

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Now that's a damn good idea ...

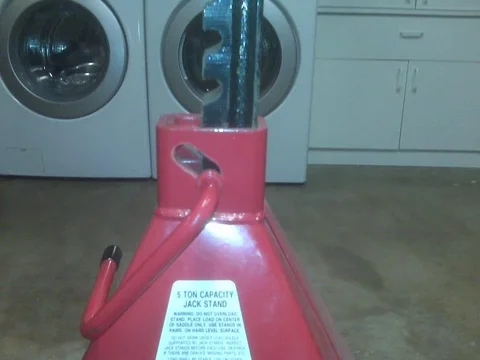

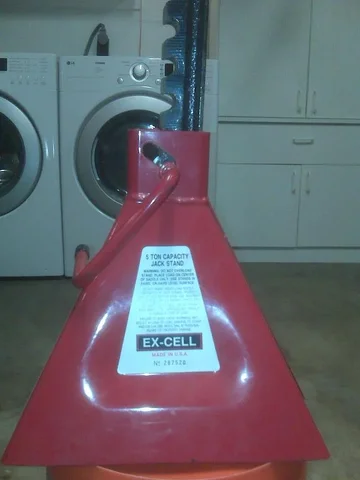

I have 3 ton jackstands (similar to these) that my brother gave me for Christmas a few years back... I think he got it from Costco... Anyway they have the thick 1/2" steel pins to lock them in place which IMO makes them a little bit safer.

would be pretty easy to add a pin like that to other jacks too in fact but does not seem that necessary. The pawl should not be able to come out if engaged properly (key word).

????

Did you read the original post?

That's EXACTLY what failed, the pawl, or the steel it was attached to.

The pin adds a 2nd, and completely independent, support point. So it makes a HUGE difference. It takes the load and spreads it over two teeth on the vertical riser, and between the pawl and the additional pin.

I doubt that. There is probably no realistic way to have both pawl and pin support the riser significantly at the same time. The tolerances would have to be much smaller than is likely the case for this type of construction. The pin being smaller apparently would likely not support the weight either if the main pivot fails. Is it better to have it, yes probably, would it make a HUGE difference in practice? I don't think so unless it's as big as the main pivot.

VERY nice. Any idea how much they run.

I like the 3 ton models because of the lifting range, and they are rated per jack, with this stand I'd feel much safer than even the 6 ton HF units (3 ton per jack rating).

I gotta tell you, I thought they'd be more.

maybe a group buy is in order?

dude, your tougher than a 3 ton jack, an ARB and 6000 plus pounds of fine Toyota engineering. Do you know how rare that is?

So glad your'e still with us.

Maybe for Christmas Santa will let you get a lift installed in your driveway? Then we can all come over and use it standing up!

kidding aside, that's an amazing story. great pic of Millie.

Let us know if you need help getting it all back together.

Glad you are ok, must be in good health to survive such an impact. Those jack stands look like the HF ones I have, but mine are the 6 ton ones....get the bigger ones for your truck.

It really wasn't her fault though.

Since buying the new LX a month ago, I've gone nuts gathering parts. To date I've have or have in transit:

OME lift

ARB front bumper

Snorkel

295/85 16 Hankooks

OEM Aux tank and filler neck, switch, ect...

lots of other interior knick knacks.

To make a short story longer... two and a half weeks ago, I was under the front of the truck. I had done the lift on three corners with just the driver's front to go. I still had the passenger front tire off and the frame supported on a jackstand (mistake)

I was on my left side removing the steering damper when the jackstand failed. That's right, it didn't slip off, it failed. The truck came down on the brake disk and the ARB hit me on the right collar bone compressing my chest into the driveway. I was yelling loud enough that the nieghbors and my wife came running.

Continuing the stupidity, I wouldn't let my wife call for an ambulance. After 15 minutes of laying in the driveway trying to breathe, I put my tools away and jacked the truck up and put the tire back on. That's when I realized I was running on shock and adrenaline so my wife drove me to the ER.

Sorry for the long post, but it's only been a couple of weeks and I've only been able to get up without help and dress myself for a few days. The final outcome is no broken bones (I don't know how I managed that). Lots of torn cartilage on the left side of my chest so everything pops out of place if I sneeze, a very screwed up shoulder, and unbelievable soreness and pain. I also had to be monitored for several days becuase of a suspected tear in my left lung.

The moral of the story is:

DON'T TRUST YOUR LIFE TO CHEAP CHINESE STEEL!!!

I do take responsibility for the stands being too small. I figured a 3ton stand would be plenty for one corner. I've used then on numerous cruisers for years. In my defense. I've had these stands so long that I didn't know they were HF specials. I should be dead. The really scary part to me is my three year old was helping me. Fortunately, I make her sit on the porch when the truck is up on stands. I can't imagine what she'd have had to deal with if she had watched me kick off. I'm hoping to finish the lift in a couple of weeks (it may be longer) and get some progress pics.

Anyway, here's the pics. Sorry for the quality of the first one. My wife was trying to be sneaky. The second and third show what happened to the stand.

Sorry you got hurt, But I can see exactly what happened, You where to cheap to buy a set of 12 tons to lift it as high as you needed so you over extended the saddle bar to where the bottom was resting on top of the paw instead of being locked in a grove where it would have been locked and very unlikely to fail unless the side of the collar blew out I can see the orange paint of the bottom and ANy lawyer could too. So I really wouldn't attempt to make this about a bad product, There is no possible way if you had em set up correctly it would fail like that. you can not support a vehicle with the saddle sitting on top of the locking paw. It has nothing to do with how the stand is made. It was lack of common sense that got you hurt. I find it funny you guys complain about import jackstands when your toyota is made by the same people.