Back to the driver's door....

I have speakers mounted in the trim panels ... but when I fitted them .. I also fitted connectors in the wiring to enable the trim panels to be removed easily (without having to cut or unsolder the wires):

Note: You've already seen me cut the speaker wires on the passenger door. I will cut those same wires on this door too - because whenever a door is opened or closed, those wires twist. And unless I replace them now, they are likely to fail there from "metal fatigue in all the copper strands" some time in the future. (I like to replace that section of wiring approx every 10 years.)

So I probably should just show myself cutting these wires really since this wiring is ultimately going to be replaced.

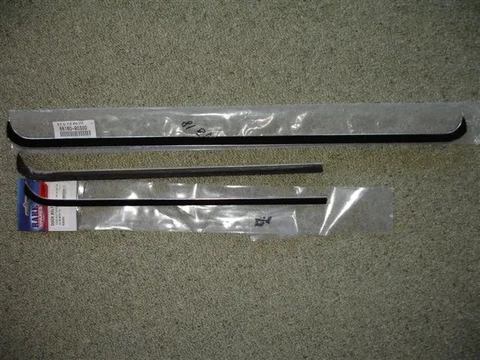

And here is the plastic sheeting that sits beneath the trim panel:

Without this, if you were driving along a side-slope in heavy rain - the water would drain down the window glass (window wound up of course) and drip on the inside of the trim panel (through the holes) making the trim board go rotten and fall to bits! ......Not good.

I cut that sheet myself (from the polythene sheeting sold in garden centres) and will be making up a nice clean replacement too. (Note the little flaps I melted onto the inside surface to direct the water back inside the door cavity.)

And here is the door with the plastic removed. (PS. I hold the plastic in place with bits of "Blue tack". I have found this works best after trying various alternatives. Because it stays soft rather that setting hard.)

All that black stuff inside the door cavity is "congealed Fishoilene" that I have periodically sprayed liberally inside to try and stop rust.

Fishoilene is made from fish oil - and is an old-fashioned rust-preventative that I still think works better than any other (but only in certain situations).

A lot of people won't use fish oil because your vehicle stinks of fish for a few months after application and it never really sets hard. (Although deoderized versions are now being sold.)

)

)

.

.

So I probably should just show myself cutting these wires really since this wiring is ultimately going to be replaced.

So I probably should just show myself cutting these wires really since this wiring is ultimately going to be replaced.