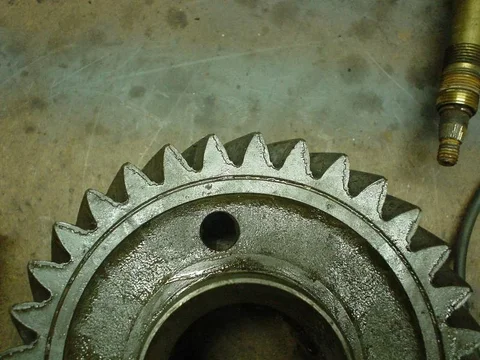

It always feels good to take something that looks completely roached and make it look shiny and new but just because it looks great doesn't mean that it is mechanically great. Doesn't mean it isn't either, just be on the lookout for potential problems. You don't want to destroy whatever new parts you put in when something else wears oddly or fails. It may be pits in the gears that cause excessive wear, or slop in a retainer that can cause premature failure.

On the other hand you can get it together and feel very good about turning a turd into a jewel, just keep tabs on the magnetic drain plug, maybe take good pictures of the gears to compare wear to later and give it a shot. The rebuild experience is great regardless

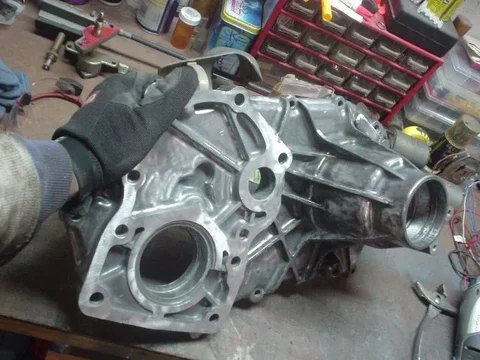

Looks great so far.

Bret

On the other hand you can get it together and feel very good about turning a turd into a jewel, just keep tabs on the magnetic drain plug, maybe take good pictures of the gears to compare wear to later and give it a shot. The rebuild experience is great regardless

Looks great so far.

Bret

Not sure everybody will get that but it made me LMAO!!!!

Not sure everybody will get that but it made me LMAO!!!!

know this was $200!" And quickly hid it amongst the other piles of parts in the shop!

know this was $200!" And quickly hid it amongst the other piles of parts in the shop!