Here I have finished painting the axle, I hope it holds up, I think I should have painted it with Rust bullet instead, but oh well...

Finally I get around to the issue with the bent skid plates... mine were non-repairable and I did not have time for fabbing up something, so I weighed my options and called Budbuilt and ordered (2) so I have protection all the way back to the gas tank. Unfortunately, they arrived on valentines day weekend and the

was not too happy with the attention the truck was getting attention....

I also did some repair work to the slightly rusty battery tray with some of the leftover truck bed liner in a can... worked great.

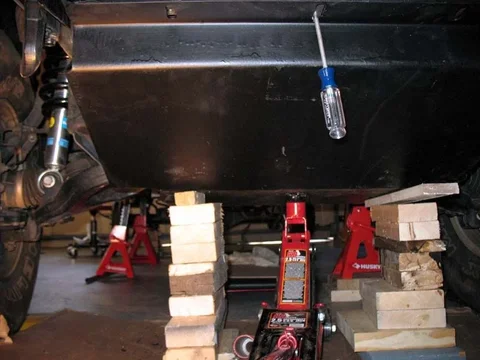

Now, I am done with painting the skid plates, what a pain

And I am ready to install... but I have to weld.

You see, one of the mounting points on the truck for the factory skid plate was bent from the tear off, so I beat it a few times to get it straight and then jacked it up, wire wheeled it and hoped for the best. I have my Dad's old HF wire welder 110v, I have no clue how to use it, so I plug it in and read the ****py instructions and make a go at it.

Here is my first try... why the spatter??? I think from what I have read, it is inherent in MIGs without gas and yes.... I have a cheap welder.

[FONT="]GUess what? it did not hold, so off came the plate and I broke out the MIG again and cranked up the heat and poured it on..

THis time it held.[/FONT]

Well, that is all for tonight folks

PS feel free to comment on my welding job

was not too happy with the attention the truck was getting attention....

was not too happy with the attention the truck was getting attention....