Hi Folks,

With a nice long weekend and no real plans, I was able to start on my DC charging and power system. I'll start with the disclaimer that this is a work in progress, and while it all works "in my head", I'm sure I'll encounter a few surprises along the way. This is a bit of a departure from the usual dual-battery or Redarc BCDC install. I wanted something with a little more flexibility in design and future upgrades. I also don't want to touch the factory power system. The result was a child born of two inspirations. The first was the Victron Van and second @Eric Sarjeant's recent dissent build. The real challenge was to boil all these components (charging/switching/protection) into a small package like the dissent build without a dissent budget (although none of this stuff is cheap).

Goals:

Simple single Power cable from engine bay to DC system

All aux DC devices will run on house LifePo4 battery in the drawers

Handle draw of 100+ amp when needed

Be compact (Needs to fit behind trekboxx)

Be hidden (No clutter)

Be serviceable

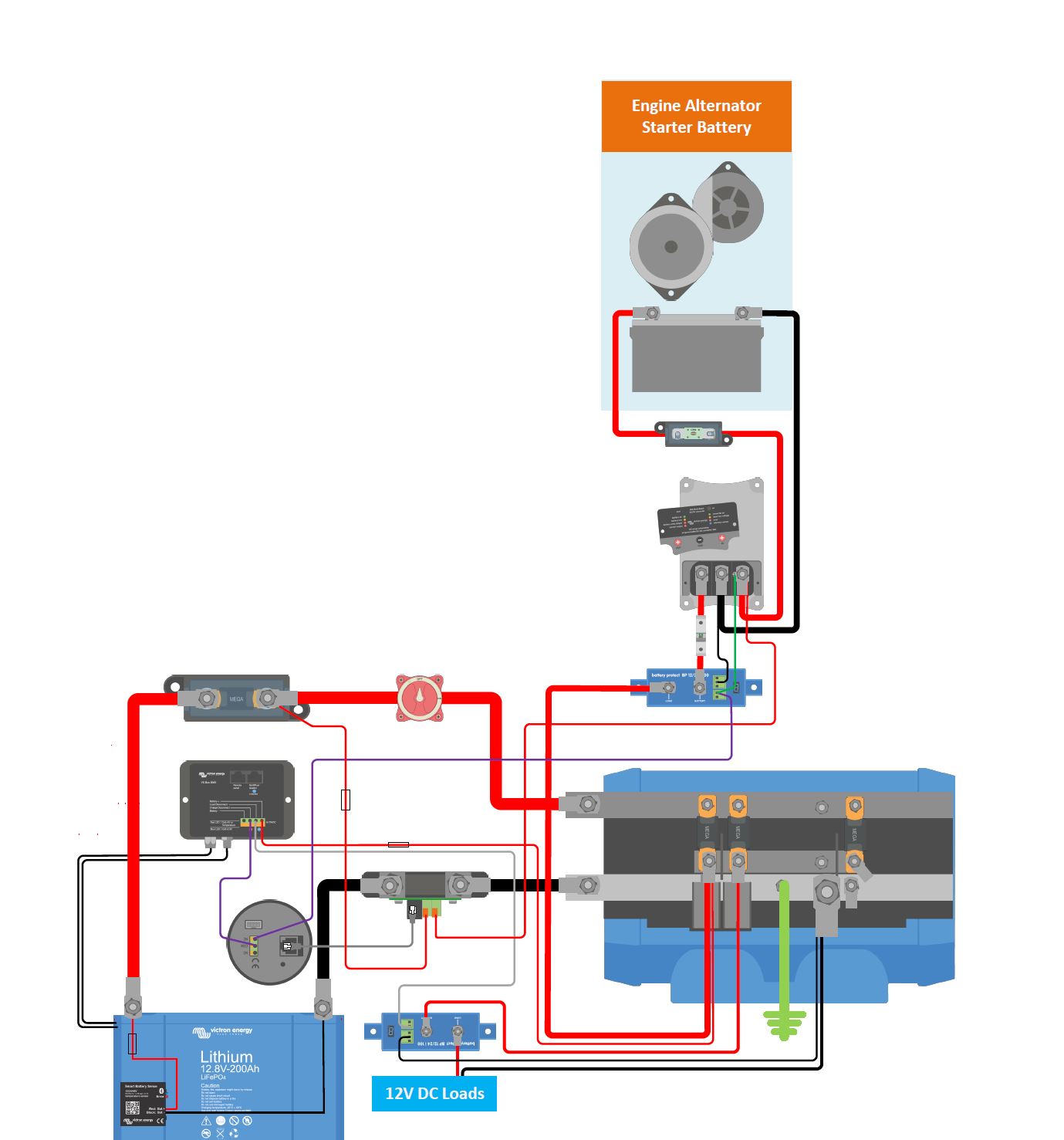

1 - DC design (This is a rip-off the Victron van plans provided online)

2 - Form Factor (Making it all fit behind the second row) ...and yes, I used pipe cleaner to layout my cable runs.

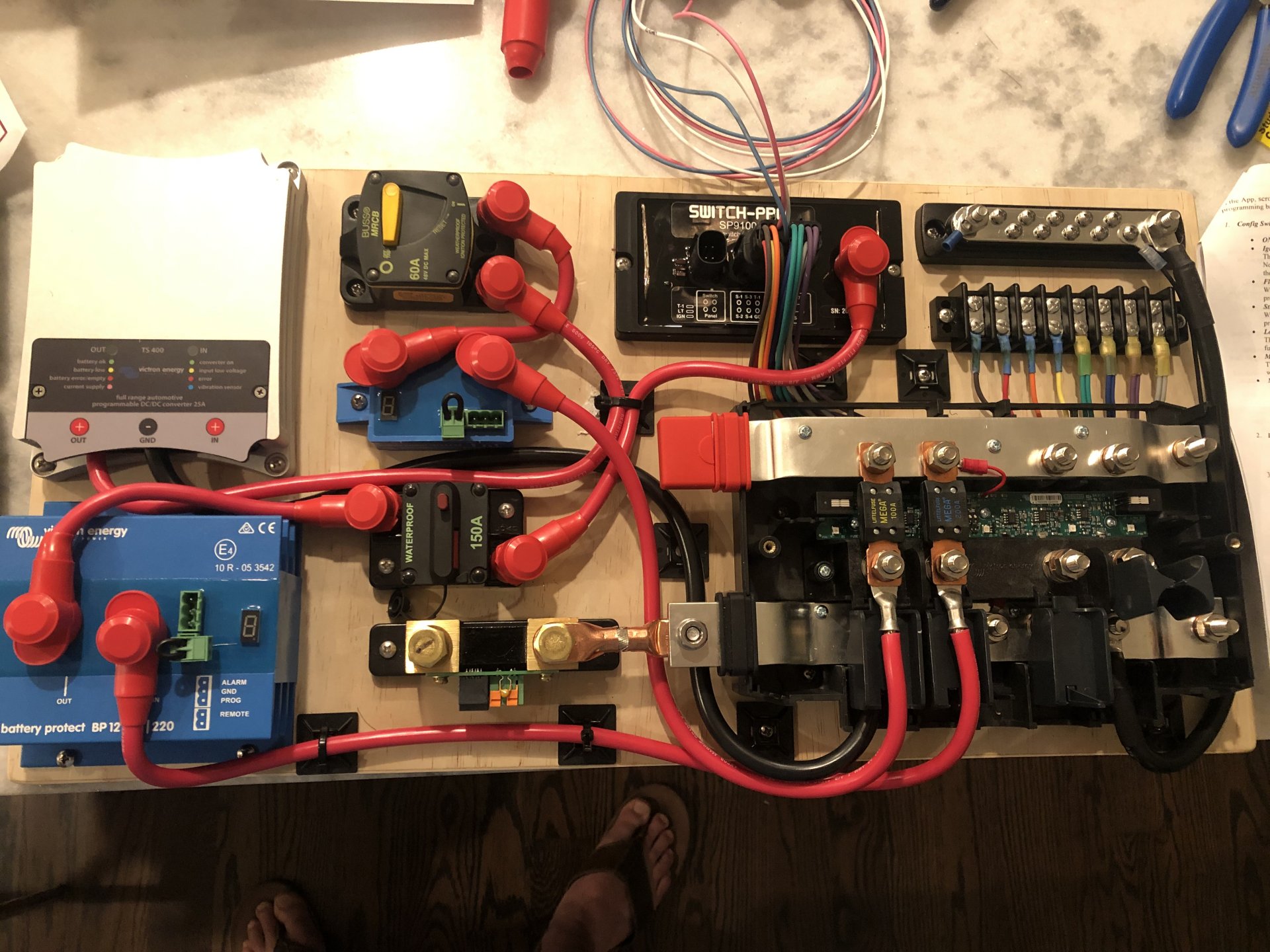

3 - Assembly (As of 5/24/20...will update when finished)

So far it all seems to be working out. The hardest part was arranging everything so they fit behind the seats. There is very little room. The Victron lynx distributor is HUGE! I was expecting something half the size. I wish they made a baby 500 amp version. It's complete overkill, but I really like the distribution design and it will make it extremely easy to add solar and inverter at a later date. I fused my charging system at 60 amps even though it's a 25 amp charger. Originally I wanted a 50 amp charger, but after a lot of research, 50 amp charging was going to be too hard on the alternator at idle and a fairly significant cost increase.

Enjoy! I'll try to update the first post as it evolves.

With a nice long weekend and no real plans, I was able to start on my DC charging and power system. I'll start with the disclaimer that this is a work in progress, and while it all works "in my head", I'm sure I'll encounter a few surprises along the way. This is a bit of a departure from the usual dual-battery or Redarc BCDC install. I wanted something with a little more flexibility in design and future upgrades. I also don't want to touch the factory power system. The result was a child born of two inspirations. The first was the Victron Van and second @Eric Sarjeant's recent dissent build. The real challenge was to boil all these components (charging/switching/protection) into a small package like the dissent build without a dissent budget (although none of this stuff is cheap).

Goals:

Simple single Power cable from engine bay to DC system

All aux DC devices will run on house LifePo4 battery in the drawers

Handle draw of 100+ amp when needed

Be compact (Needs to fit behind trekboxx)

Be hidden (No clutter)

Be serviceable

1 - DC design (This is a rip-off the Victron van plans provided online)

2 - Form Factor (Making it all fit behind the second row) ...and yes, I used pipe cleaner to layout my cable runs.

3 - Assembly (As of 5/24/20...will update when finished)

So far it all seems to be working out. The hardest part was arranging everything so they fit behind the seats. There is very little room. The Victron lynx distributor is HUGE! I was expecting something half the size. I wish they made a baby 500 amp version. It's complete overkill, but I really like the distribution design and it will make it extremely easy to add solar and inverter at a later date. I fused my charging system at 60 amps even though it's a 25 amp charger. Originally I wanted a 50 amp charger, but after a lot of research, 50 amp charging was going to be too hard on the alternator at idle and a fairly significant cost increase.

Enjoy! I'll try to update the first post as it evolves.