- Thread starter

- #21

I don't give up easily...

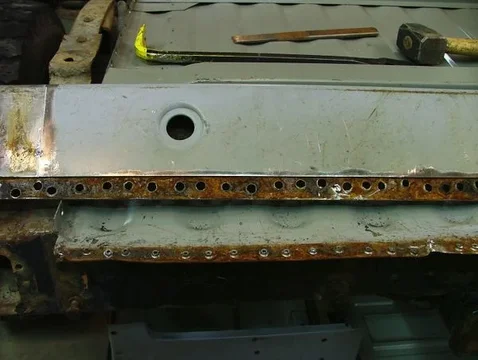

WOW, about describes my feelings once I pulled up the bedliner. I did know the body was bad when I bought it but as the frame and engine were strong, I didn't care. I had to have the truck.

As for giving up on it, I like a challenge and it was then pretty easy to decide what parts to keep and what not Furthermore, I wasn't in a financial position to change my luck. I knew the frame was good. The hard top parts also seemed to be good. Rust in all the usual places and I'm confident I can fix the problem areas.

Furthermore, I wasn't in a financial position to change my luck. I knew the frame was good. The hard top parts also seemed to be good. Rust in all the usual places and I'm confident I can fix the problem areas.

Cheers and thanks.

Jim

WOW, I would have just given up on it and bought another truck!

WOW, about describes my feelings once I pulled up the bedliner. I did know the body was bad when I bought it but as the frame and engine were strong, I didn't care. I had to have the truck.

As for giving up on it, I like a challenge and it was then pretty easy to decide what parts to keep and what not

Cheers and thanks.

Jim

Last edited: