So I stumbled on this while trying to figure out a way to bench test my ARB lockers and wanted to share.

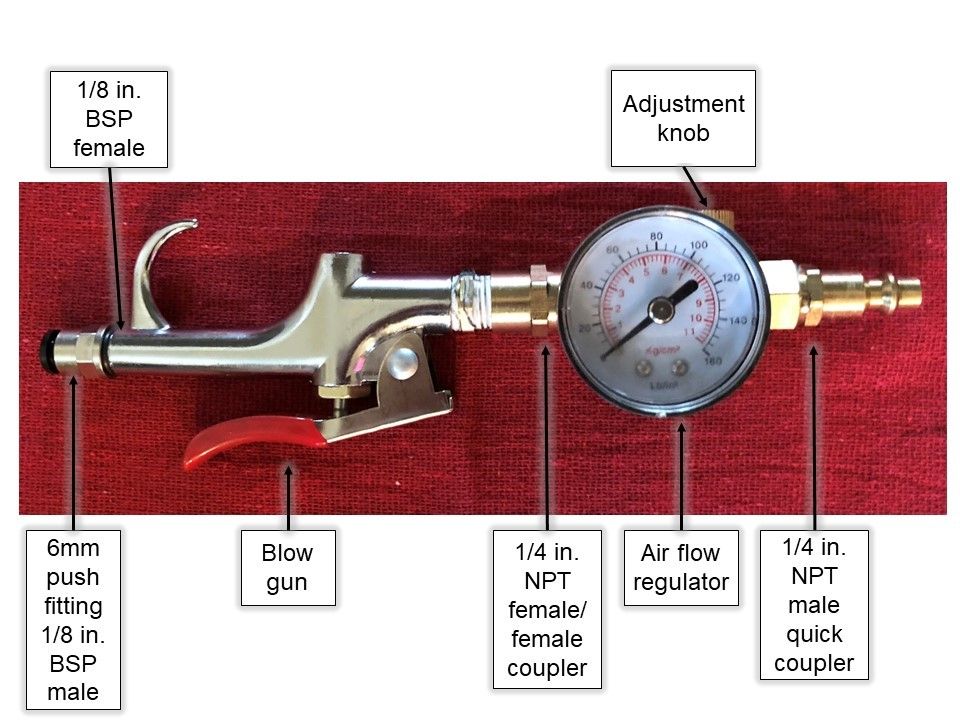

It turns out that the female fitting at the end of a Harbor Freight air blow gun (I assume other brands as well) is 1/8 in. BSP. So the 6mm press fitting to 1/8 in. BSP coupler that comes with the locker will tread into the blow gun. I put this in line with an air flow regulator to push ~80 PSI to the locker. Worked perfectly! Cost was about $12 vs. $85.

It turns out that the female fitting at the end of a Harbor Freight air blow gun (I assume other brands as well) is 1/8 in. BSP. So the 6mm press fitting to 1/8 in. BSP coupler that comes with the locker will tread into the blow gun. I put this in line with an air flow regulator to push ~80 PSI to the locker. Worked perfectly! Cost was about $12 vs. $85.

Last edited: