Awl_TEQ

Supporting Vendor

- Thread starter

- #141

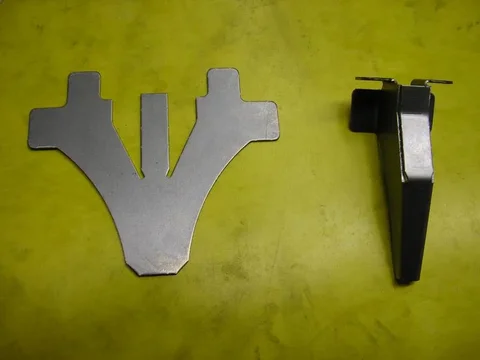

So you'll have to trust me ( ) because I have no pictures. I made the brackets that weld to the bed floor cross members today. These are the brackets that sit on the rubber bushings and the bolts pass through to fasten the bed to the frame. They are 10 Ga.

) because I have no pictures. I made the brackets that weld to the bed floor cross members today. These are the brackets that sit on the rubber bushings and the bolts pass through to fasten the bed to the frame. They are 10 Ga.

It's a lot more fun with pictures isn't it?

.

It's a lot more fun with pictures isn't it?

.