Howdy y'all. It has been a while since I've been on Mud. I have been in between projects and tinkering with the vehicles I already had after selling the 5.3 FJ60 I built on here a few years back. After a string of odd vehicle purchases and trades, I wound up with this! A 1970 4x4 F250 "Highboy". It was relatively rust free save for some of the most common spots and had a solid 300cid with 4-speed manual which reminded me of my 60 series before I swapped it. My initial plans were to fix the important rust, get it driving, and just enjoy having a beater truck. Obviously that ship has sailed as evidenced by this here build thread.

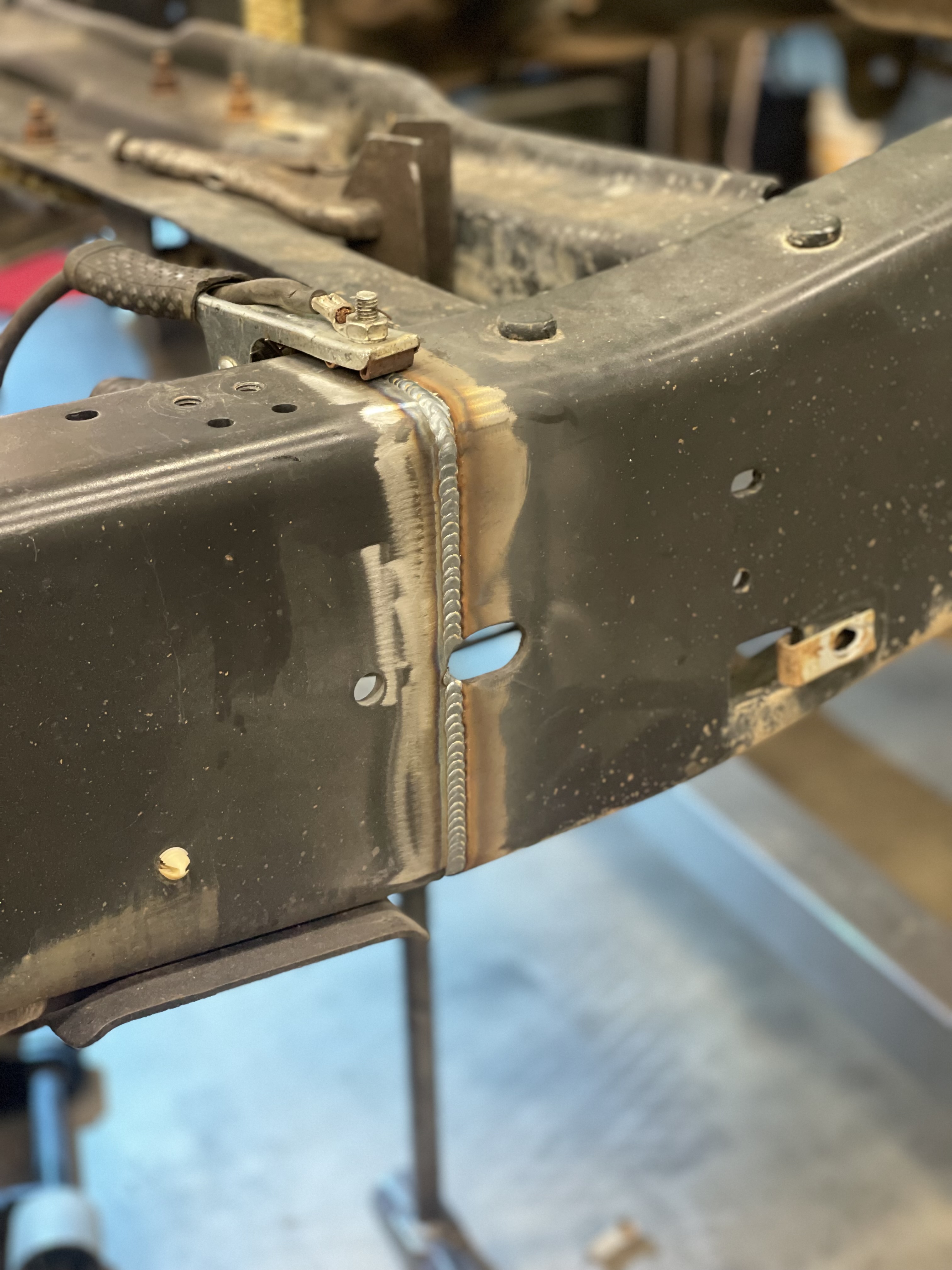

Now why didn't I just leave well enough alone and get the truck on the road ASAP so I could enjoy it? Truth be told, I had a couple of regrets re: my old 60 series build, namely, I really wished I had linked the front end. Do front leaf springs work? Yes. Are they pleasant to drive every day? Meh. Since this is a body swapped chassis (original highboy frame/driveline, F100 body) I decided to ditch my original plan altogether and sit it all on top of a 2017 F250 chassis. This addressed my desire for coil springs up front but more importantly, the 2017 chassis I purchased was cheaper than the cost to redo all of the bushings, joints, lines, etc. on the highboy chassis.

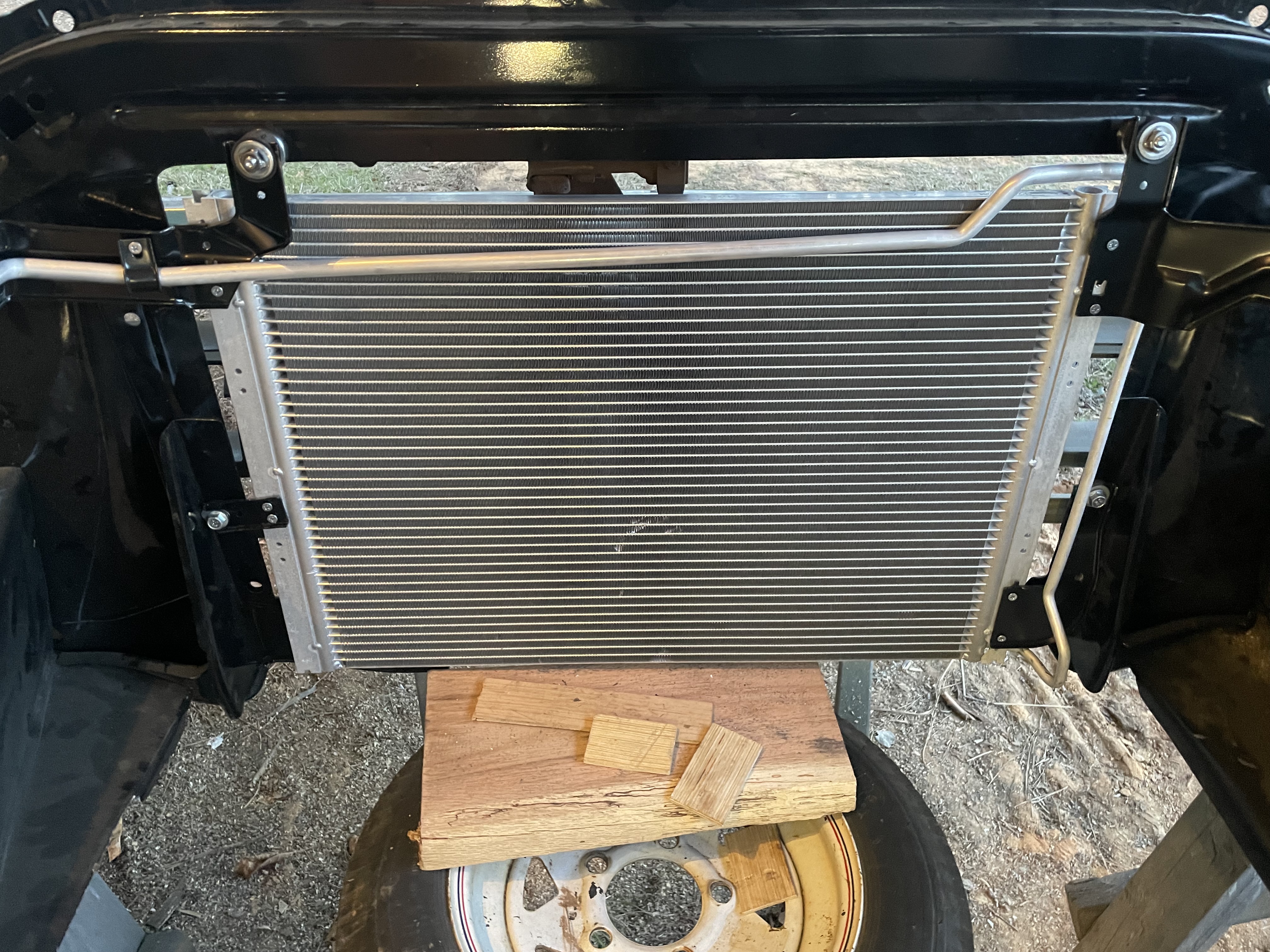

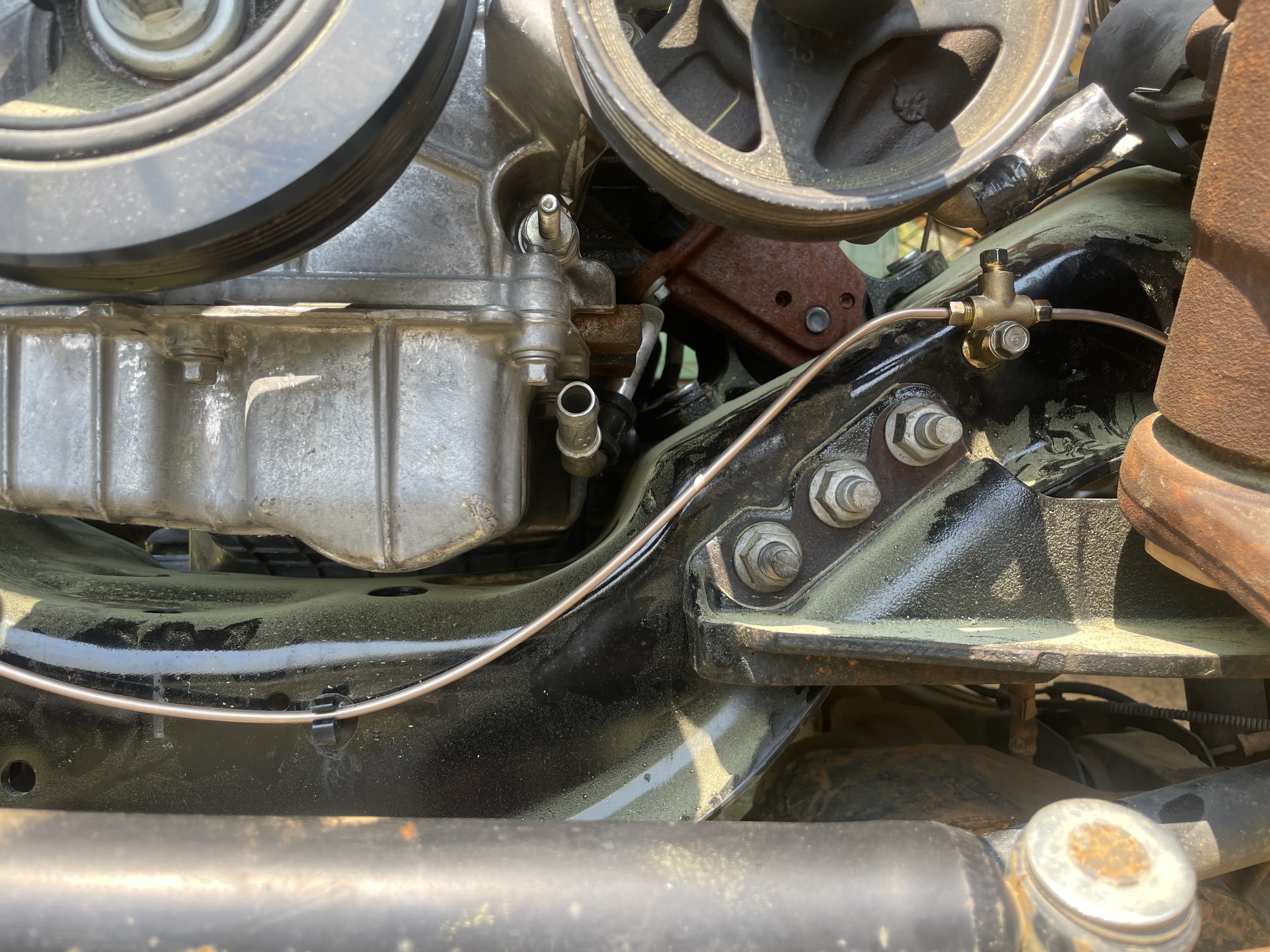

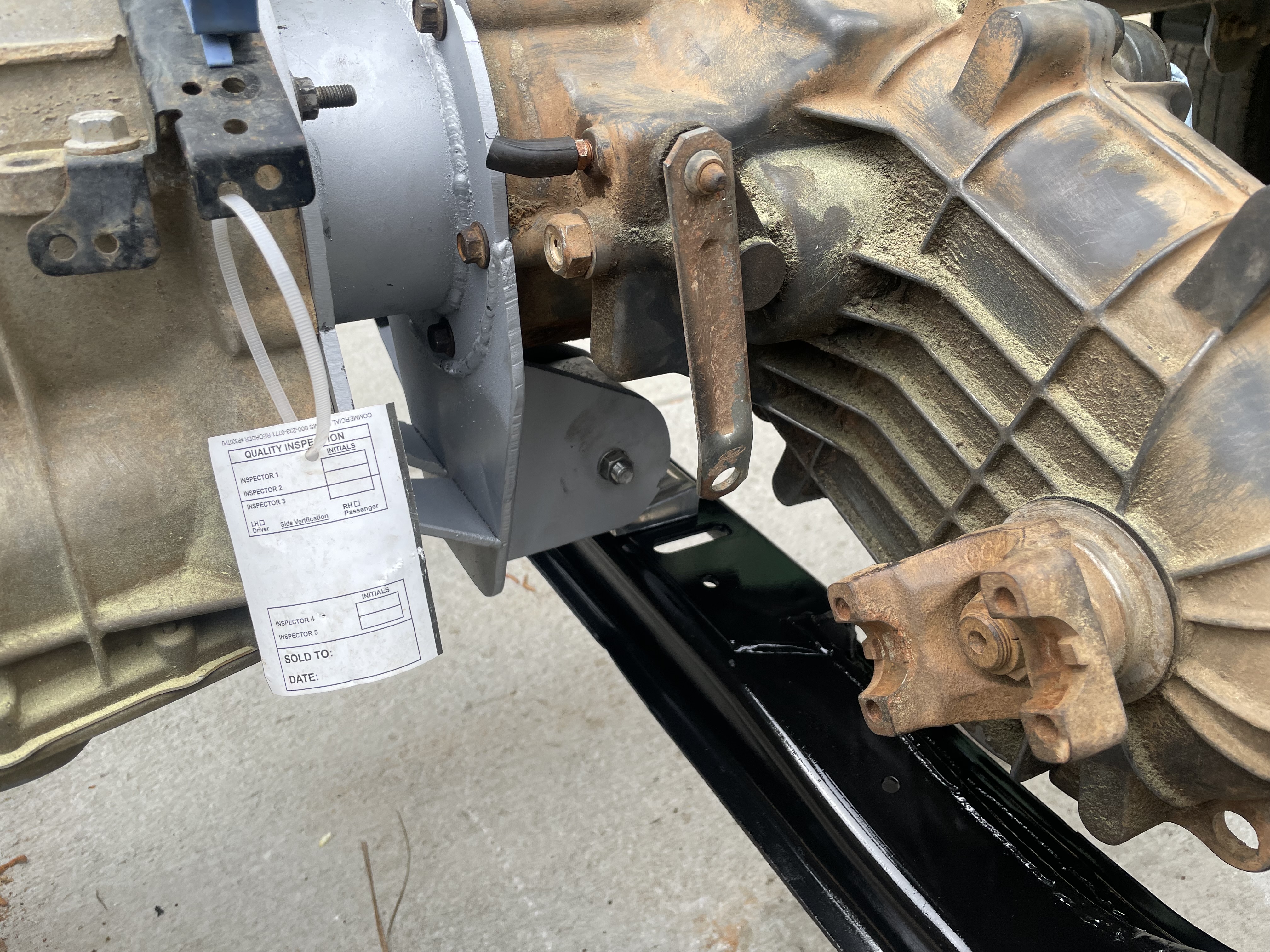

The other cool thing about buying a new frame is that it's not rusty, has very good axles front and rear (rear has a factory locker, who knew?) and a 7.3 gasoline engine *should* bolt right in with very few modifications. So I bought one. I also bought a 6r80. You'd think this is rich man's territory now but I found a basically new take-out engine that fell off of a forklift for a mega deal. Busted a valve cover, smashed a coil pack, and broke the throttle body but all of these were easily fixed.

Now why didn't I just leave well enough alone and get the truck on the road ASAP so I could enjoy it? Truth be told, I had a couple of regrets re: my old 60 series build, namely, I really wished I had linked the front end. Do front leaf springs work? Yes. Are they pleasant to drive every day? Meh. Since this is a body swapped chassis (original highboy frame/driveline, F100 body) I decided to ditch my original plan altogether and sit it all on top of a 2017 F250 chassis. This addressed my desire for coil springs up front but more importantly, the 2017 chassis I purchased was cheaper than the cost to redo all of the bushings, joints, lines, etc. on the highboy chassis.

The other cool thing about buying a new frame is that it's not rusty, has very good axles front and rear (rear has a factory locker, who knew?) and a 7.3 gasoline engine *should* bolt right in with very few modifications. So I bought one. I also bought a 6r80. You'd think this is rich man's territory now but I found a basically new take-out engine that fell off of a forklift for a mega deal. Busted a valve cover, smashed a coil pack, and broke the throttle body but all of these were easily fixed.