Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FJ62 A440F Trans Rebuild

- Thread starter Cruiser Jimmy

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?$150?! Holy crap!

Then I wonder why the hell the Rodney one (at least I assume it's from Rodney) at West Coast Cruisers sells for $1400.

I wonder if I could get that and the McNamara gear from Valley Hybrids....

Then I wonder why the hell the Rodney one (at least I assume it's from Rodney) at West Coast Cruisers sells for $1400.

I wonder if I could get that and the McNamara gear from Valley Hybrids....

It has been awhile since I have rebuilt auto trans and never a cruiser auto but, you should always replace the torque converter because you can't get all the old fluid out or see the condition of the unit. Basically I think of it as rebuilding an engine and leaving a few quarts of old oil in the pan that probably have dirt, metal pieces, clutch pieces etc. in it. Then you blow all that crap through all your hard work.

Cruiser Jimmy

Moderator

- Thread starter

- #24

Gathering Parts and Toyota Expert Knowledge

The last couple days has been consumed with ordering parts and tracking down why my TC failed in the first place, especially why my TC failed. But let me backup for a little bit. When I worked for a tier I supplier to Toyota I had the luxury of being taught 5-Why analysis and Genshi Genbutsu from our quality department.

Genshi Genbutsu means 'go and see'.

The essence of Genshi Genbutsu is go and see for yourself the condition that is having an effect, usually the bad effect when we're talking about building things. This philosophy runs all the way up the chain to the plant manager at a production facility but not limited to.

5-Why is a problem solving technique. Essentially you can ask 5 questions that will get to the root of a problem (in the corporate world properly trained of course.)

This was the reason why I cut my TC open to find out the condition, but back then, I didn't finish the 5-Why. I showed my finding to shops around the area but they could not tell me why. Which brings me to present day.

I ordered my rebuild kit from Transtar and discovered that the sales rep is into Cruisers also. He really likes 45's, who doesn't. Transtar rebuilds TC but Dacco specializes in it. I went over to Dacco and showed my TC to the parts guys and I asked him about it. The Dacco rep referred me to a shop that was not 3 miles from my house, didn't know about this shop back then. (Dacco also reworks parts like output shaft and you can buy hard parts from them.)

I found myself at the local shop waiting for someone to talk to. It was show and tell as I had my TC with me. I showed the tech my TC and the first thing he said was 'that's pretty burnt'. The is where the continuation of 5-Why comes into play.

He explained that there are bushing in the oil pump that should be checked or replaced. For an understanding, these bushing are like 2F cam bearing but act differently. One of the purposes of the bushing is to limit the fluid pressure by keeping it in the TC and applying pressure to the lockup. Or in other words, fluid pressure goes to this location and lubricates, allowed to leak it drains back into the hydraulic system. Showing the bushing from a Highlander he was working on, the tech said that this is a common design for Toyota. At lockup speed the fluid is restricted and pressure is applied to the lockup. If the bushing is worn then fluid pressure leaks which causes the lockup to slip and starts to heat up.

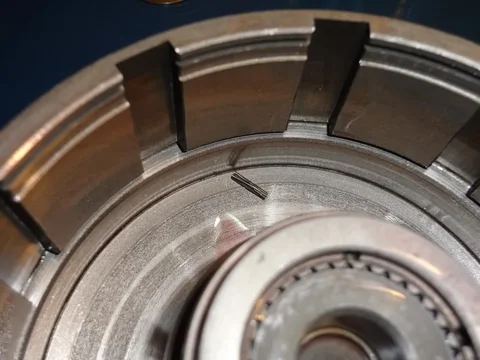

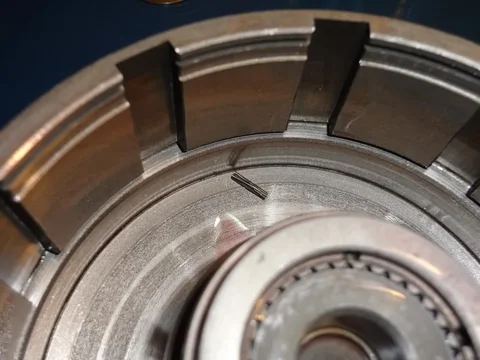

Getting back to my 80 trans that I still have, I moved the Overdrive Planetary Gear inside the Oil Pump and there was a lot movement. See the pic for illustration.

With this 62 trans there's no movement but I'm going to replace the bushings in the pump as a precaution anyways.

The manual does stated that you should measure the inside diameter of the bushings on the pump, if out of spec replace the pump. These parts are really expensive so I having the bushing replaced.

Now the question becomes did I measure the pump's bushings on the 80. I can't remember, I've slept since then and had a lot of really great beer.

OD gear and pump. Bushing in between these on the inside.

Stator pump side.

Stator bushing. (1 of 2: There is one on the other end also.)

The last couple days has been consumed with ordering parts and tracking down why my TC failed in the first place, especially why my TC failed. But let me backup for a little bit. When I worked for a tier I supplier to Toyota I had the luxury of being taught 5-Why analysis and Genshi Genbutsu from our quality department.

Genshi Genbutsu means 'go and see'.

The essence of Genshi Genbutsu is go and see for yourself the condition that is having an effect, usually the bad effect when we're talking about building things. This philosophy runs all the way up the chain to the plant manager at a production facility but not limited to.

5-Why is a problem solving technique. Essentially you can ask 5 questions that will get to the root of a problem (in the corporate world properly trained of course.)

This was the reason why I cut my TC open to find out the condition, but back then, I didn't finish the 5-Why. I showed my finding to shops around the area but they could not tell me why. Which brings me to present day.

I ordered my rebuild kit from Transtar and discovered that the sales rep is into Cruisers also. He really likes 45's, who doesn't. Transtar rebuilds TC but Dacco specializes in it. I went over to Dacco and showed my TC to the parts guys and I asked him about it. The Dacco rep referred me to a shop that was not 3 miles from my house, didn't know about this shop back then. (Dacco also reworks parts like output shaft and you can buy hard parts from them.)

I found myself at the local shop waiting for someone to talk to. It was show and tell as I had my TC with me. I showed the tech my TC and the first thing he said was 'that's pretty burnt'. The is where the continuation of 5-Why comes into play.

He explained that there are bushing in the oil pump that should be checked or replaced. For an understanding, these bushing are like 2F cam bearing but act differently. One of the purposes of the bushing is to limit the fluid pressure by keeping it in the TC and applying pressure to the lockup. Or in other words, fluid pressure goes to this location and lubricates, allowed to leak it drains back into the hydraulic system. Showing the bushing from a Highlander he was working on, the tech said that this is a common design for Toyota. At lockup speed the fluid is restricted and pressure is applied to the lockup. If the bushing is worn then fluid pressure leaks which causes the lockup to slip and starts to heat up.

Getting back to my 80 trans that I still have, I moved the Overdrive Planetary Gear inside the Oil Pump and there was a lot movement. See the pic for illustration.

With this 62 trans there's no movement but I'm going to replace the bushings in the pump as a precaution anyways.

The manual does stated that you should measure the inside diameter of the bushings on the pump, if out of spec replace the pump. These parts are really expensive so I having the bushing replaced.

Now the question becomes did I measure the pump's bushings on the 80. I can't remember, I've slept since then and had a lot of really great beer.

OD gear and pump. Bushing in between these on the inside.

Stator pump side.

Stator bushing. (1 of 2: There is one on the other end also.)

62 reverse "clunk"

After reading this last post could this be a root cause of the "reverse clunk" ? I have always thought the root cause was pressure related because in the morning when I shift into reverse my trans acts as if it was new but after a fluid heat up or level (my thought) it "clunks" hard going into reverse. I installed a mac gear and that did not help. I have a feeling someone knows the root cause of the 62 reverse clunk but for some reason he or she does not post it . Awesome info I commend you.

After reading this last post could this be a root cause of the "reverse clunk" ? I have always thought the root cause was pressure related because in the morning when I shift into reverse my trans acts as if it was new but after a fluid heat up or level (my thought) it "clunks" hard going into reverse. I installed a mac gear and that did not help. I have a feeling someone knows the root cause of the 62 reverse clunk but for some reason he or she does not post it . Awesome info I commend you.

The last couple days has been consumed with ordering parts and tracking down why my TC failed in the first place, especially why my TC failed. But let me backup for a little bit. When I worked for a tier I supplier to Toyota I had the luxury of being taught 5-Why analysis and Genshi Genbutsu from our quality department.

Genshi Genbutsu means 'go and see'.

The essence of Genshi Genbutsu is go and see for yourself the condition that is having an effect, usually the bad effect when we're talking about building things. This philosophy runs all the way up the chain to the plant manager at a production facility but not limited to.

5-Why is a problem solving technique. Essentially you can ask 5 questions that will get to the root of a problem (in the corporate world properly trained of course.)

This was the reason why I cut my TC open to find out the condition, but back then, I didn't finish the 5-Why. I showed my finding to shops around the area but they could not tell me why. Which brings me to present day.

I ordered my rebuild kit from Transtar and discovered that the sales rep is into Cruisers also. He really likes 45's, who doesn't. Transtar rebuilds TC but Dacco specializes in it. I went over to Dacco and showed my TC to the parts guys and I asked him about it. The Dacco rep referred me to a shop that was not 3 miles from my house, didn't know about this shop back then. (Dacco also reworks parts like output shaft and you can buy hard parts from them.)

I found myself at the local shop waiting for someone to talk to. It was show and tell as I had my TC with me. I showed the tech my TC and the first thing he said was 'that's pretty burnt'. The is where the continuation of 5-Why comes into play.

He explained that there are bushing in the oil pump that should be checked or replaced. For an understanding, these bushing are like 2F cam bearing but act differently. One of the purposes of the bushing is to limit the fluid pressure by keeping it in the TC and applying pressure to the lockup. Or in other words, fluid pressure goes to this location and lubricates, allowed to leak it drains back into the hydraulic system. Showing the bushing from a Highlander he was working on, the tech said that this is a common design for Toyota. At lockup speed the fluid is restricted and pressure is applied to the lockup. If the bushing is worn then fluid pressure leaks which causes the lockup to slip and starts to heat up.

Getting back to my 80 trans that I still have, I moved the Overdrive Planetary Gear inside the Oil Pump and there was a lot movement. See the pic for illustration.

With this 62 trans there's no movement but I'm going to replace the bushings in the pump as a precaution anyways.

The manual does stated that you should measure the inside diameter of the bushings on the pump, if out of spec replace the pump. These parts are really expensive so I having the bushing replaced.

Now the question becomes did I measure the pump's bushings on the 80. I can't remember, I've slept since then and had a lot of really great beer.

OD gear and pump. Bushing in between these on the inside.

View attachment 714581

Stator pump side.

View attachment 714582

Stator bushing. (1 of 2: There is one on the other end also.)

View attachment 714583

Very interesting! I'll have to give the OD shaft a wiggle when I get home and see if its got any play. I plan to do the same as you did on the rebuild but also add a few extra clutches and tweak the VB a bit.

Cruiser Jimmy

Moderator

- Thread starter

- #27

Very interesting! I'll have to give the OD shaft a wiggle when I get home and see if its got any play. I plan to do the same as you did on the rebuild but also add a few extra clutches and tweak the VB a bit.

Nice!! I was directionally challenged back in '93 when I entered college. I should have been an engineer instead of going into business. I'd like to look at a schematic and find the improvement areas.

(If your trans temp is below 180º then you should not have anything to worry about until you tweak yours.)

Very interesting! I'll have to give the OD shaft a wiggle when I get home and see if its got any play. I plan to do the same as you did on the rebuild but also add a few extra clutches and tweak the VB a bit.

I'm curious to see how you go about adding extra clutches. I'm sure you'll have to machine something to make it work, but more clutches = more friction surface area, so it's a great idea. I know Wholesale Automatic Transmissions adds extra clutches when they do their Extreme rebuild of 80 series autos.

Buck, very interesting theory. If you know for a fact your splines are good and that you don't have any play anywhere else in the driveline, it'd definitely be something worth looking into.

Jimmy, that's a helluva finding. I dig your troubleshooting philosophy. Might have to adopt that myself

Well I gave the o/d shaft a good check on my A440F tonight and it did not move at all, I could feel no movement.

I am a total auto noob, I have plans but not actually done it. I have a good friend that is a transsmission tech and Longbow on here has provided some very good information as well. Adding clutches does require machine work (laith) and some precise measurments. The VB work is totally black magic to me right now.

I am a total auto noob, I have plans but not actually done it. I have a good friend that is a transsmission tech and Longbow on here has provided some very good information as well. Adding clutches does require machine work (laith) and some precise measurments. The VB work is totally black magic to me right now.

... One of the purposes of the bushing is to limit the fluid pressure by keeping it in the TC and applying pressure to the lockup. Or in other words, fluid pressure goes to this location and lubricates, allowed to leak it drains back into the hydraulic system. Showing the bushing from a Highlander he was working on, the tech said that this is a common design for Toyota. At lockup speed the fluid is restricted and pressure is applied to the lockup. If the bushing is worn then fluid pressure leaks which causes the lockup to slip and starts to heat up...

Subscribing!

Very interesting. I wonder if there is an external port that would allow you to connect a gauge to monitor the lockup pressure.

The TC on my FJ62 seems to slip when at locked-up speed and when hot. When cold, lock-up seems solid as indicated by the tach needle - no movement of the tach needle in response to slight changes in engine power. When hot, minor changes in engine power result in +/-100 rpm change as indicated by the tach so I'm assuming that the TC lockup is not workig 100%.

Fj62 Rusty Bungs

Spook, I went to get a full exhaust put on today and found out it could not be done because of me Bungs were rusty. I'm am now going to machine some Bungs for them to use (toyota heated o2 senders) .I have seam to have fell into a product that me can produce and after I can get the tooling program done I will offer them to all the ih8mud guy's at a discount.

I will post some production pics when me get a chance.

Peace

Spook, I went to get a full exhaust put on today and found out it could not be done because of me Bungs were rusty. I'm am now going to machine some Bungs for them to use (toyota heated o2 senders) .I have seam to have fell into a product that me can produce and after I can get the tooling program done I will offer them to all the ih8mud guy's at a discount.

I will post some production pics when me get a chance.

Peace

I put a cfi302 with a nv4500 into a 1988 4runner that the pigs hate !

Nice!! I was directionally challenged back in '93 when I entered college. I should have been an engineer instead of going into business. I'd like to look at a schematic and find the improvement areas.

(If your trans temp is below 180º then you should not have anything to worry about until you tweak yours.)

Maybe even the 3rd gear lockup could be fathomed as well... I have a dead (well badly wounded... have reverse but no forwards) a440f and this info will go into the memory banks for later.. good thread man

Cruiser Jimmy

Moderator

- Thread starter

- #34

Updates:

I'm still waiting on the TC and bushings for the oil pump to come in. The TC is actually used for a work stand on some of the parts that you rework/check.

I got the replacement output shaft in from dallen341 and it's in superior condition. The packaging of the shaft was a work of art, there was no damage that was going to happen as a result of him efforts to package. Thanks Dallen.

This OS had some residual clutch material from it's tranny so a multiple wash in the parts washer was needed. The manual calls for using ATF or Kerosene to wash the parts with, I've got Kerosene.

The second pic is a piece of debris from the machining process. However this debris was pressed in place from a locking ring inside the housing. After 330K I don't think it was going anywhere. It was good that I found it after is became dislodged.

I'm still waiting on the TC and bushings for the oil pump to come in. The TC is actually used for a work stand on some of the parts that you rework/check.

I got the replacement output shaft in from dallen341 and it's in superior condition. The packaging of the shaft was a work of art, there was no damage that was going to happen as a result of him efforts to package. Thanks Dallen.

This OS had some residual clutch material from it's tranny so a multiple wash in the parts washer was needed. The manual calls for using ATF or Kerosene to wash the parts with, I've got Kerosene.

The second pic is a piece of debris from the machining process. However this debris was pressed in place from a locking ring inside the housing. After 330K I don't think it was going anywhere. It was good that I found it after is became dislodged.

Cruiser Jimmy

Moderator

- Thread starter

- #35

The bushings finally came in from the vendor. I ran the pump over to the tranny shop where the guys that have been so helpful pressed the old bushings out and put the new bushings in. There was one new bushing that needed to be honed down because it was over spec, the O/D shaft would not fit. I took the bore hone to it and got it in spec. There are only a couple of these bushings that call for measurements in the entire transmission. These are pretty critical since they help to keep fluid in the TC while in lockup. The sun gear drive bushing does not call for a measures so I assume it's just used as a guide.

The pump has three bushings total. 1 on the body side and 2 on the stator side (cover side.)

Here's pictural progress thus far.

This bushing in pressed into the pump housing. This is the bushing that will ride against the torque converter input shaft.

New bushing.

Honing of the new bushing cover side.

The pump has three bushings total. 1 on the body side and 2 on the stator side (cover side.)

Here's pictural progress thus far.

This bushing in pressed into the pump housing. This is the bushing that will ride against the torque converter input shaft.

New bushing.

Honing of the new bushing cover side.

Cruiser Jimmy

Moderator

- Thread starter

- #36

Cruiser Jimmy

Moderator

- Thread starter

- #37

Subscribing!

Very interesting. I wonder if there is an external port that would allow you to connect a gauge to monitor the lockup pressure.

There is a port on the outside of the housing assemble, along with many others. The manuals only show procedures for checking the condition of the trans to diagnose problems. It does not show what port you are specifically checking.

I'll post up a thought about this tomorrow after I deduce (the best I can) which port is going to be effected by your request.

Cruiser Jimmy

Moderator

- Thread starter

- #38

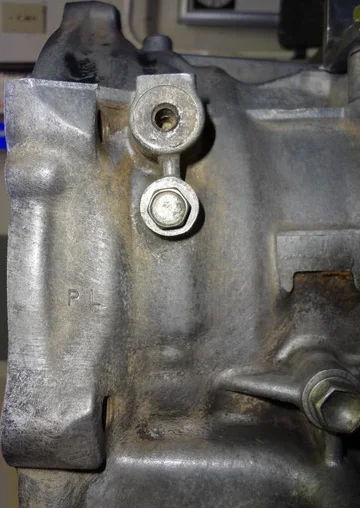

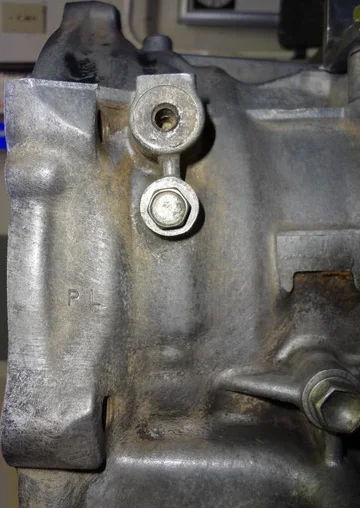

astr,

This one of two ports that the manual refers to a line pressure test is on the drivers side front of the trans. (The other port is to test governor pressure and in the back of the trans, drivers side.)

This port goes directly into the oil pump. It's buttoned up so I'd have to crack it back open to probe more. I suspect it's just pump pressure.

The FSM states to test this port for a line test. The pressure should read between 158~193 psi at stall speed of 1950 ±150 rpms. Idle reading is 53~61 psi.

The other possibility would be the oil cooler circuit.

After tracing the TC circuit during lockup I found that this capped off angled threaded port goes to the delivery of the oil cooler. At least I'm pretty sure it's deliver and not return. But I don't see 150+ psi running through the cooler circuit.

This one of two ports that the manual refers to a line pressure test is on the drivers side front of the trans. (The other port is to test governor pressure and in the back of the trans, drivers side.)

This port goes directly into the oil pump. It's buttoned up so I'd have to crack it back open to probe more. I suspect it's just pump pressure.

The FSM states to test this port for a line test. The pressure should read between 158~193 psi at stall speed of 1950 ±150 rpms. Idle reading is 53~61 psi.

The other possibility would be the oil cooler circuit.

After tracing the TC circuit during lockup I found that this capped off angled threaded port goes to the delivery of the oil cooler. At least I'm pretty sure it's deliver and not return. But I don't see 150+ psi running through the cooler circuit.

Thanks for your research. I looked at the hydraulic diagram for the A440F but couldn't tell exactly how the lockup is activated. It show two lines feeding oil to the torque converter but it is unclear how they are used to activate the lockup clutch.

I know that oil from the torque converter is directed to the cooler but then just dumps into the pan so there should be no pressure in those lines.

I know that oil from the torque converter is directed to the cooler but then just dumps into the pan so there should be no pressure in those lines.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)