My 60 is nice and clean for 350,000 miles, but has a bad exhaust leak. Guessing I’ve also got a bit of a vacuum leak at the manifold as well. From the later photos you can see how badly it needs the headers. Oh and while I’m putting in the new headers I might as well try out a Trollhole Carb. This will be the biggest job I've done myself on the 60 so feel free to point out mistakes or add advice. Using the FSMs and the search function to get me through the job.

Ordered:

Headers: Mark's Offroad

Gasket: Mark's Offroad, was thinking about remflex, but I'll be having the manifold resurfaced anyway so hopefully the other gasket will hold up better (the Remflex that is on it now is badly delaminated.)

Carb: Trollhole

New vacuum lines all around, including PCV hoses and valve

Outsourcing the following, if anyone has reccomendations near Ventura let me know:

Resurfacing Manifold and shaving header to a machine shop

Exhaust from header back to an exhaust shop, not sure if I can find someone to work on my Florida registered (military) desmogged 60 in CA, so may have to borrow a friend who can weld. Or drive it to Nevada with open headers and earplugs...

Day 1: Removal of parts- took me about 2 hours including time to wait for penetrating oil on a stuck bolt.

#1: Pictures to help remember where everything goes, could be helpful to someone else as well. Also labeling the hoses when I remove them.

#2 Air box removed, all lines to air box tagged.

#3 All carb vacuum lines, solenoid, mechanical linkage for throttle and cable for choke were detached and tagged. Carb was then removed from insulator plate (four nuts hold it to four studs that come up through the insulator plate from the manifold). Carb is going to be set aside for apossible future rebuild after I get up and running with the Trollhole.

#4: Insulator plate removed from manifold, two 12mm bolts, and one more vacuum hose attached to the insulator. One of the bolts was stuck real good, had to use an extractor socket, will have to order a new bolt.

#5. With the insulator plate off, it was not too difficult to get to the bolts and nuts holding the manifold and headers on. Only the header hangs from the outermost bolts, so to start I loosened all the others, (four bolts and two studs with nuts in the center). These weren’t too difficult for me, I guess they weren’t over-torqued last time. Finally two more lines will need to be removed from the manifold, then it can be lifted out.

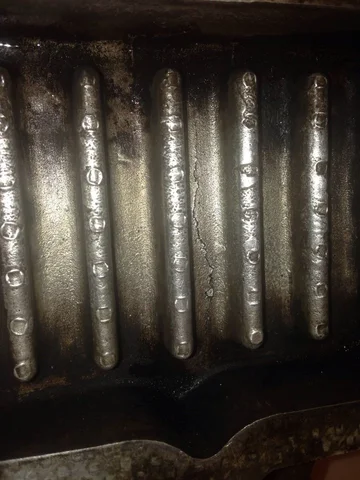

#6. Manifold out and ready to clean before a thorough inspection for cracks and warping

That's where I'l leave it for now.

Ordered:

Headers: Mark's Offroad

Gasket: Mark's Offroad, was thinking about remflex, but I'll be having the manifold resurfaced anyway so hopefully the other gasket will hold up better (the Remflex that is on it now is badly delaminated.)

Carb: Trollhole

New vacuum lines all around, including PCV hoses and valve

Outsourcing the following, if anyone has reccomendations near Ventura let me know:

Resurfacing Manifold and shaving header to a machine shop

Exhaust from header back to an exhaust shop, not sure if I can find someone to work on my Florida registered (military) desmogged 60 in CA, so may have to borrow a friend who can weld. Or drive it to Nevada with open headers and earplugs...

Day 1: Removal of parts- took me about 2 hours including time to wait for penetrating oil on a stuck bolt.

#1: Pictures to help remember where everything goes, could be helpful to someone else as well. Also labeling the hoses when I remove them.

#2 Air box removed, all lines to air box tagged.

#3 All carb vacuum lines, solenoid, mechanical linkage for throttle and cable for choke were detached and tagged. Carb was then removed from insulator plate (four nuts hold it to four studs that come up through the insulator plate from the manifold). Carb is going to be set aside for apossible future rebuild after I get up and running with the Trollhole.

#4: Insulator plate removed from manifold, two 12mm bolts, and one more vacuum hose attached to the insulator. One of the bolts was stuck real good, had to use an extractor socket, will have to order a new bolt.

#5. With the insulator plate off, it was not too difficult to get to the bolts and nuts holding the manifold and headers on. Only the header hangs from the outermost bolts, so to start I loosened all the others, (four bolts and two studs with nuts in the center). These weren’t too difficult for me, I guess they weren’t over-torqued last time. Finally two more lines will need to be removed from the manifold, then it can be lifted out.

#6. Manifold out and ready to clean before a thorough inspection for cracks and warping

That's where I'l leave it for now.