- Thread starter

- #81

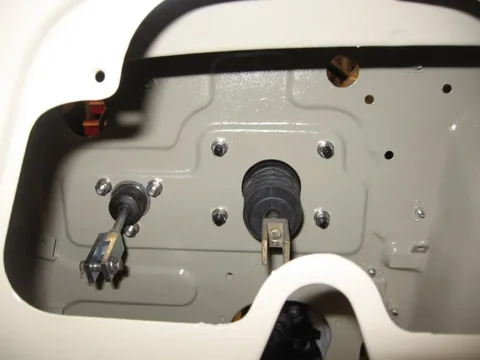

This grommet was sourced thru Toyota by measuring the holes and then locating a grommet on the spec sheet that would fit. This hole is on the drivers floor.

Blower unit prior to disassembly.

Blower unit reconditioned. Stripped rust and painted what I could. New weatherstripping seals sourced from Home Depot to seal the flap inside the unit just like it was originally and also on the intake and exhaust side. I was considering painting the blower housing but did not want to significantly change the OEM appearance.

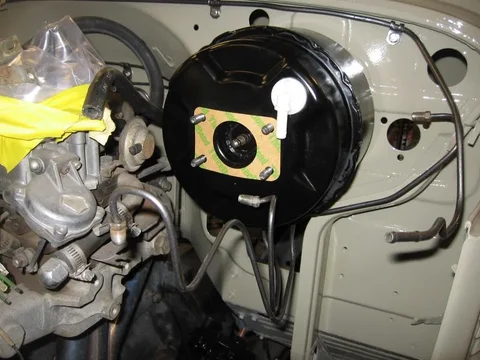

Bolted up with new stainless steel hardware and ready to go!

Last edited: