- Thread starter

- #41

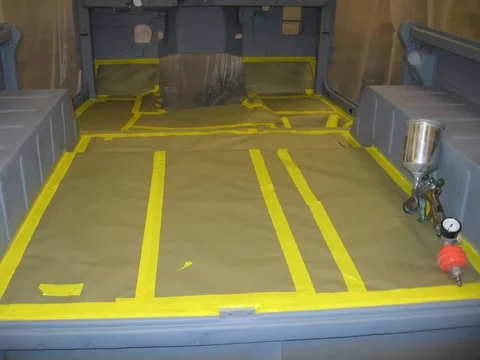

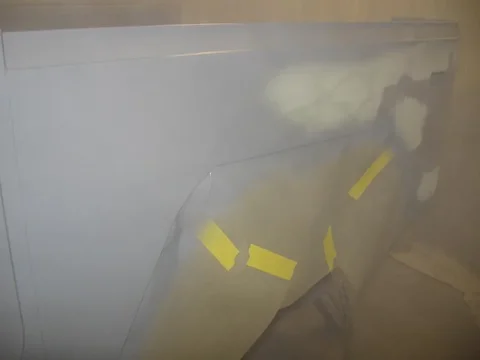

Layed down 2-3 coats of fresh epoxy primer to seal the tub. It smoothed out nicely. The filler all looks good and I do not see any spots that need any further attention. The interior of the tub looks so good that it makes me reconsider whether or not I even want to spray the EZ Liner on it. Having one consistent color, like the grey primer, gives a nice visual effect as it comes together. It makes me imagine how similar my tub is at this point to what it was like on the Toyota factory paint line 36 years ago........all clean fresh and looking new! However, I know that having the EZ Liner on the floor of the tub will give so much better protection. I'll let the epoxy primer dry over night then mask off everything else but the floor so I can spray the EZ Liner on Friday morning. I think while the EZ Liner dries Friday, I will prime the frame and perhaps topcoat it if it dries well enough.

Last edited: