Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carb tuning and frustration...

- Thread starter gregnash

- Start date

-

- Tags

- carburetor

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?LAMBCRUSHER

SILVER Star

Thanks I appreciate your honest comment. But again, 'faking an idle' ?? Meaning off choke correct? And honestly 200 rpms? A nearly 30 year old truck, hmm. When I get mine all back together I'll be very curious to see if mine would idle that low.

did you read the thread? > Cruiser Carb Info - Land Cruiser Tech from IH8MUD.com

LAMBCRUSHER

SILVER Star

I guess I remember now...lean drop is done FROM COLD...

you fake the fast idle speed from a scratch built carb. FSM has close settings for baselining...

roughly set fast idle with truck off, set mix screw out to be rich (my truck needed 4 turns to be right) set idle speed close to 450, 500-ish. start truck WITH CHOKE ON and let warm up. (fast idle kicks throttle open to bypass idle circuit) after truck is warm, SLOWLY open choke- here is where even tiny vacuum leaks cause issues...if you have a tiny vacuum leak, your truck won't want to idle slowly, and when you open the choke, the rig dies. a decent carb on a decent warm motor WILL IDLE 450-500. 200 might be a bit of a stretch- but not by much, if any. If the speed is much over 750 to keep running without choke , chances are your past the idle circuit to compensate for a vacuum leak and you'll never baseline the carb. starting with a low speed ensures a good setting. I like to tune down to idle mix, and tune up to rpm. it becomes mishy mashy to find the right spot once one thing gets overshot...

so, to recap my madness...

truck OFF:

1. rought set timing to 7*

2. rough set FAST IDLE SPEED

3. set mixture screw overly rich

4. set speed to SLOW- I find it doesn't take alot of plate push to increase speed alot, which is why I say screw just bumping the plate to start- you can always add more; starting too can be misleading down the line...

5. close choke

truck ON:

1. set fast idle to lowest steady speed

2. slowly open choke- truck should not die

3. set idle speed to lowest steady speed below 650 rpm

4. set timing to 7*

5. turn mix screw IN a little at a time till idle just drops- takes a second to notice the change- it is not immediate

6. back mix screw out about a 1/4 turn or so to max vacuum

7. advance timing to max vacuum, then retard timing about 1" hg vacuum.

sorry I had forgotten the bit about needing to be cold and starting from a fast idle.

and my insistance on a slow idle speed is to eliminate accidental overcompensation of underlying issues with too much throttle plate, thus negating any tuning. I do hope this makes more sense.

you fake the fast idle speed from a scratch built carb. FSM has close settings for baselining...

roughly set fast idle with truck off, set mix screw out to be rich (my truck needed 4 turns to be right) set idle speed close to 450, 500-ish. start truck WITH CHOKE ON and let warm up. (fast idle kicks throttle open to bypass idle circuit) after truck is warm, SLOWLY open choke- here is where even tiny vacuum leaks cause issues...if you have a tiny vacuum leak, your truck won't want to idle slowly, and when you open the choke, the rig dies. a decent carb on a decent warm motor WILL IDLE 450-500. 200 might be a bit of a stretch- but not by much, if any. If the speed is much over 750 to keep running without choke , chances are your past the idle circuit to compensate for a vacuum leak and you'll never baseline the carb. starting with a low speed ensures a good setting. I like to tune down to idle mix, and tune up to rpm. it becomes mishy mashy to find the right spot once one thing gets overshot...

so, to recap my madness...

truck OFF:

1. rought set timing to 7*

2. rough set FAST IDLE SPEED

3. set mixture screw overly rich

4. set speed to SLOW- I find it doesn't take alot of plate push to increase speed alot, which is why I say screw just bumping the plate to start- you can always add more; starting too can be misleading down the line...

5. close choke

truck ON:

1. set fast idle to lowest steady speed

2. slowly open choke- truck should not die

3. set idle speed to lowest steady speed below 650 rpm

4. set timing to 7*

5. turn mix screw IN a little at a time till idle just drops- takes a second to notice the change- it is not immediate

6. back mix screw out about a 1/4 turn or so to max vacuum

7. advance timing to max vacuum, then retard timing about 1" hg vacuum.

sorry I had forgotten the bit about needing to be cold and starting from a fast idle.

and my insistance on a slow idle speed is to eliminate accidental overcompensation of underlying issues with too much throttle plate, thus negating any tuning. I do hope this makes more sense.

NeverGiveUpYota

Dare me.

@LAMBCRUSHER I did read through the link and saved it as a bookmark as well. Thank you for asking. I will be printing both to make reinstall less difficult.

And that second post is FAR more descriptive. Much better. Thank you!

And that second post is FAR more descriptive. Much better. Thank you!

gregnash

Anal Retentive Analyst

- Thread starter

- #107

Ok sorry but I just haven't had time to get out with a camera to try and video what is going on. Damn tax man (my FIL) has been taking up my daylight hours when I am off work.

With that said, I have been somewhat testing what @Output Shaft and @NookShneer were hinting at about the linkage binding or sticking and the return spring on the linkage being worn.

My pedal DOES have the ability to be pulled back by the toe to lower the idle down to 650rpm-ish (based on the tach). When doing this the idle health DOES NOT change, so she will happily sit there and idle at whatever the idle speed is. So with that being said, I am wondering if my main issue is one of three things..

- The linkage return spring has become weak and no longer has the ability to fully return the linkage back to the true idle speed. This could have happened since my carb may have not been working properly or the spring was weakened when removed from linkage during rebuild

- Linkage is binding/sticking somewhere that is not allowing the spring to adequately pull the idle circuit back properly

- Something other than linkage is binding/sticking somewhere not allowing the spring to adequately pull the idle circuit back properly

If I get a chance I am going to do like @NookShneer did and either grab another spring as a "helper" or see about replacing the spring all together with another.

With that said, I have been somewhat testing what @Output Shaft and @NookShneer were hinting at about the linkage binding or sticking and the return spring on the linkage being worn.

My pedal DOES have the ability to be pulled back by the toe to lower the idle down to 650rpm-ish (based on the tach). When doing this the idle health DOES NOT change, so she will happily sit there and idle at whatever the idle speed is. So with that being said, I am wondering if my main issue is one of three things..

- The linkage return spring has become weak and no longer has the ability to fully return the linkage back to the true idle speed. This could have happened since my carb may have not been working properly or the spring was weakened when removed from linkage during rebuild

- Linkage is binding/sticking somewhere that is not allowing the spring to adequately pull the idle circuit back properly

- Something other than linkage is binding/sticking somewhere not allowing the spring to adequately pull the idle circuit back properly

If I get a chance I am going to do like @NookShneer did and either grab another spring as a "helper" or see about replacing the spring all together with another.

LAMBCRUSHER

SILVER Star

This line of thought makes sense. My cable op carb does the sticking links on the way back down to idle thing. I'm assuming it is in the linkage on the carb. A stiffer spring will just give you a shin splint. Might try hitting the link side of carb with some slip plate.

gregnash

Anal Retentive Analyst

- Thread starter

- #109

Im also wondering if the AC Pump, since I didn't soak mine in oil, has a tendency to stick a little to the walls of the AC pump area. Thus when it is going down (returning to idle) it sticks and skips a bit.This line of thought makes sense. My cable op carb does the sticking links on the way back down to idle thing. I'm assuming it is in the linkage on the carb. A stiffer spring will just give you a shin splint. Might try hitting the link side of carb with some slip plate.

The other thing that I am wondering is that if in the KEYSTER or other carb rebuild kits, if the AC Pump is slightly different size from stock. I just ordered the OEM from City Racer so when I get Alex's desmogged and rebuild mine I can compare it against the rebuild kit item.

Vae Victus

Posting more than I know

... wait, what happened? It's like watching a TV series and they ended it just before the finale....

15 months and no one asked him if there was a resolution?

15 months and no one asked him if there was a resolution?

Get used to it. Mud is the home of the unfinished paragraph.

But which OME suspension should i get?

Are oem parts worth it?

Or, what’s this noise on my truck?

Are oem parts worth it?

Or, what’s this noise on my truck?

- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

My FJ40 made a noise like that. A new flux capacitor fixed it. You should try that on your FJ62. They're totally the same.

Vae Victus

Posting more than I know

Oh I know .... Been posting unfinished threads for 5 years myself. I had just popped the popcorn though.Get used to it. Mud is the home of the unfinished paragraph.

I am actually currently working on an install right now. Once I get that taken care of my plan is to drive back to February 1987 and buy my truck brand new with a ton of new OEM parts for everyone on MUD for 1980's prices. Now, if I can only get above 60 mph....My FJ40 made a noise like that. A new flux capacitor fixed it. You should try that on your FJ62. They're totally the same.

Have had a similar high idle issue since three years. Read threads, tried many things. Recently bit the bullet and took the Aisan carb (Aussie 3F petrol model) out and apart for a clean and rebuild. Had the reassurance thta the carb was ok but the high idle issue was still there. The last test i did was to try a different throttle return spring and oh boy wjat a difference that made!!! Drives like a different car, the revs actually drop down to around 700rpm every time i change gear - i have to learn to drive it again!... wait, what happened? It's like watching a TV series and they ended it just before the finale....

15 months and no one asked him if there was a resolution?

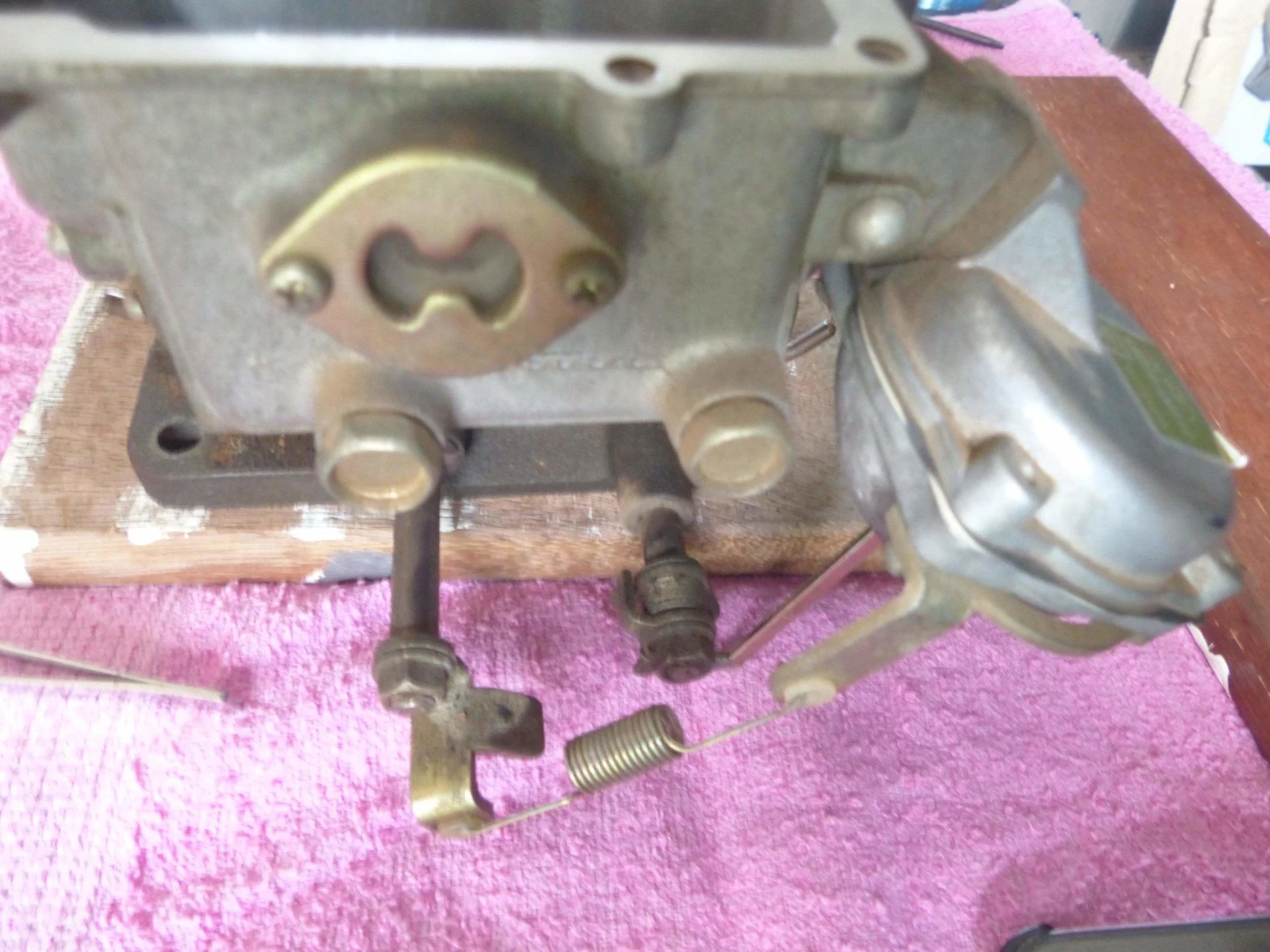

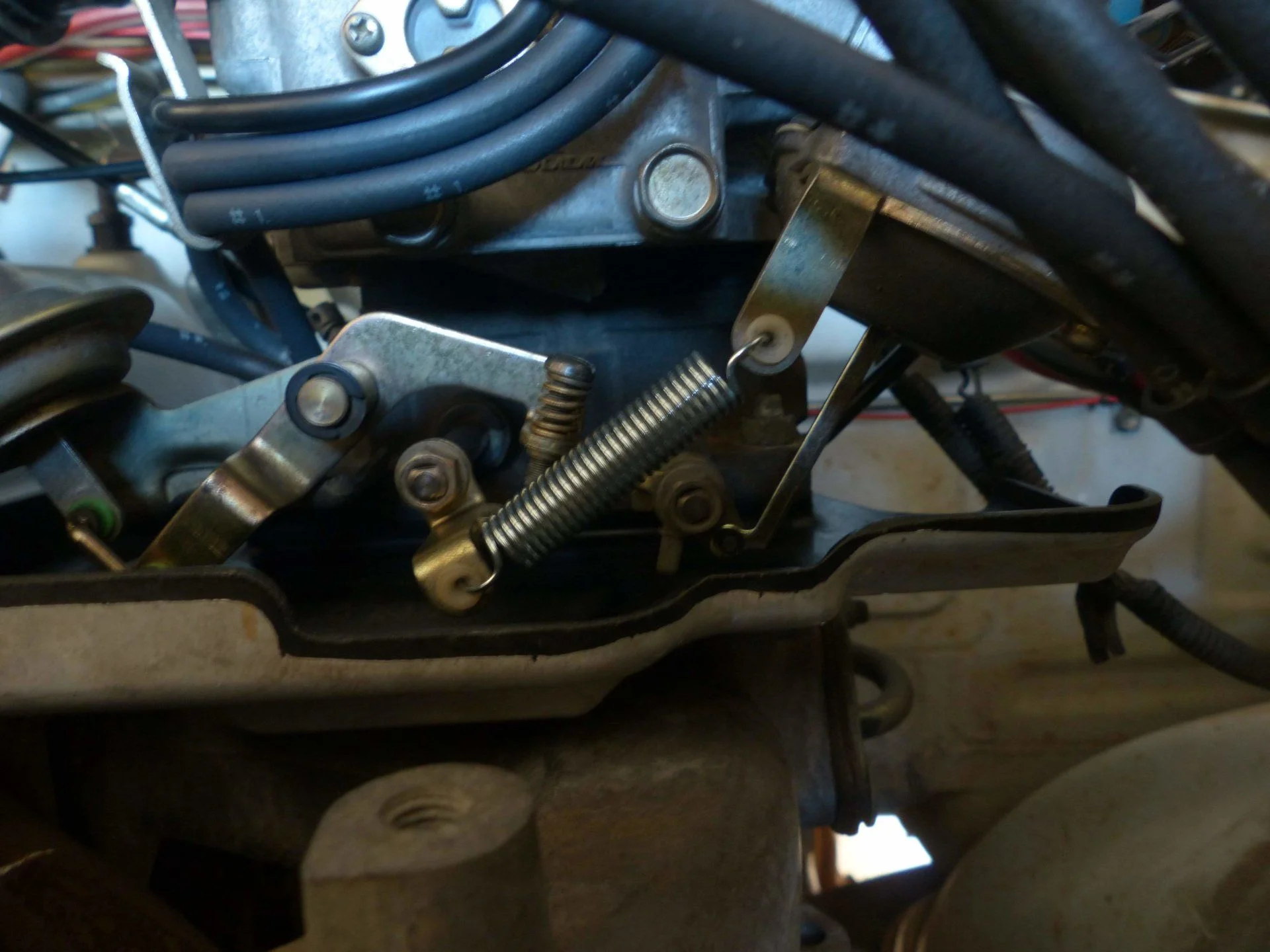

I may have cracked this nut, and hope someone else may too after reading this. Here is some pics of the original spring and the heavier one i replaced it with:

Happy New Year!

Similar threads

- Replies

- 6

- Views

- 883

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)