Make sure your butterfly flap in the exh mani is working. If it's frozen it can cause that kind of a crack from the hot exh gas constantly directed at the intake.

Good luck.

Good luck.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

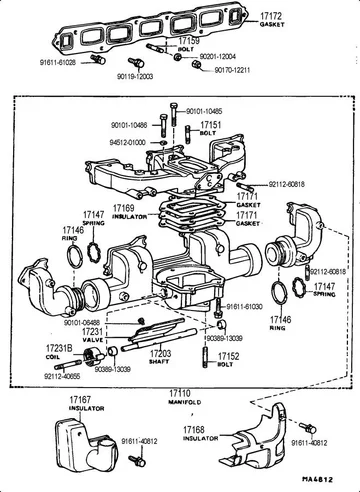

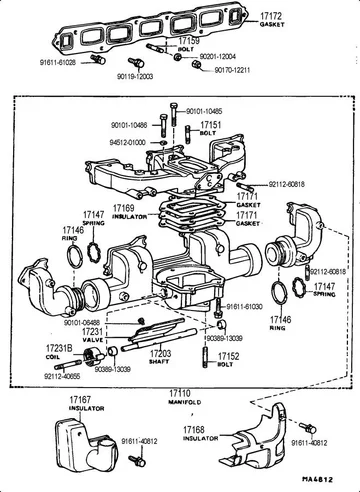

Here's some manifold pictures. The first one is the swivel end with the clip and wavy gasket showing. In the groove on the right, you might be able to see the wavy gasket in place.

What symptoms are you having Landpimp? Exhaust tick?

So.....I am "assuming" its the manifold gasket

more than a tick, does not really make noise untill 2000rpms'

So.....I am "assuming" its the manifold gasket. Can't think of anyplace else for it to leak. I have listened with some hose but its a PITA to get it down to the manifold.