Link to Part 2

See previous posts for tools, removal, and earlier steps.

Phase 7: Install tensioner screw

-Lubricate the tensioner screw with ATF or another light oil. Even better, use grease.

-Thread in the screw. Access to this head is VERY tight. I started with a wrench and then went to a 13mm socket on wobble extension and routed UNDER the ABS brake line coil atop the fender. It is a slow, slow laborious process driving in the fine thread screw 5-15 degrees at a swing. It's also possible to use a series of extensions and go through the wheel well if you remove the rubber splash guard.

-You'll slowly build belt tension. 60-80 lbs is normal; err on the high end with the Photoman overdrive reduced diameter pulleys. I used my Gates cricket gauge to check progress. I got to 76 lbs and called it good

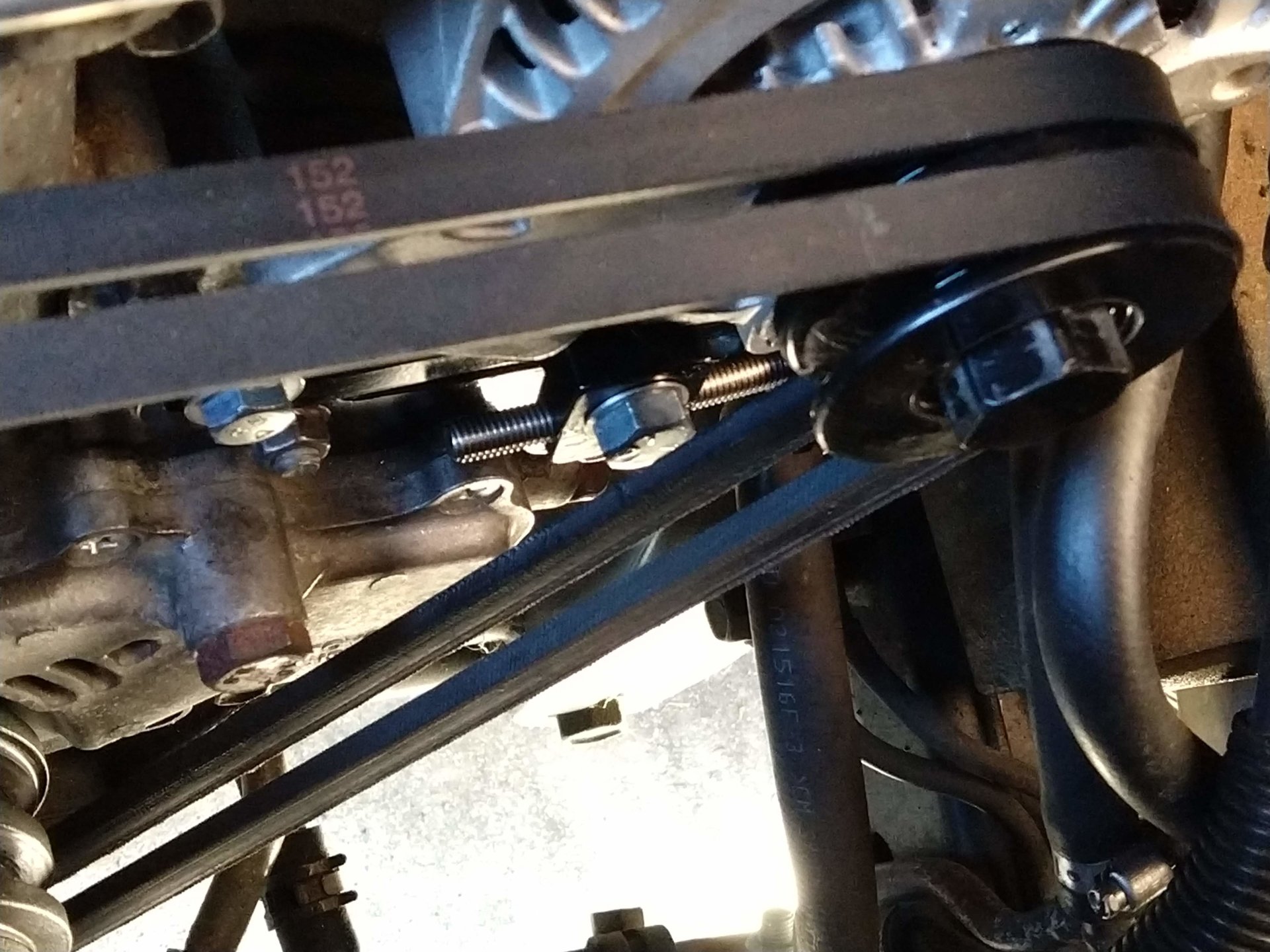

The large shiny head is the tension bolt lock bolt. The head of the tension bolt is under the pulley in this picture and accessed (with difficulty) from the side.

Phase 8: Torque bolts

-Top pivot bolt and the 7/16" bolt are 43 lb/feet

-Other bolts are 15 lb/ft.

Phase 9: Install electrical connectors

-Field connector installs using a 10mm nut. Get the cover boot back over

-I used the Photoman 3 to 4 adapter cable. Incredibly easy: the 4 port connector goes into the alternator and the existing 3 pin connector plugs into the 4" long adapter harness. I originally planned on repinning the connector but plug and play won the day here. Click click. Done.

Phase 10: Button it up.

-REINSTALL your oil filter! It will be a HUGE mess if you fail to do this. I taped the keys to the filter to ensure I did not forget this step.

-Reconnect coil wire to cap

-Reconnect the ground wire that goes fender to intake manifold

-Reinstall power steering reservoir. I went with 24 lb/feet on the bolts

-Reinstall battery box

-Install battery and clamp down

-Reconnect battery

-Reconnect overflow hose to top of radiator

Phase 11: FOD Check and QC

-Double check your oil filter is in place

-Do a through scan for tools and hardware left in the engine compartment

-Start the engine. Revel in the charge light being out and the ammeter showing a nice strong number

-Check your system voltage. Bask in your 14.1 volt glory

-Pack up the tools. Head back to the parts store with your old alternator in the box to get your core credit

See previous posts for tools, removal, and earlier steps.

Phase 7: Install tensioner screw

-Lubricate the tensioner screw with ATF or another light oil. Even better, use grease.

-Thread in the screw. Access to this head is VERY tight. I started with a wrench and then went to a 13mm socket on wobble extension and routed UNDER the ABS brake line coil atop the fender. It is a slow, slow laborious process driving in the fine thread screw 5-15 degrees at a swing. It's also possible to use a series of extensions and go through the wheel well if you remove the rubber splash guard.

-You'll slowly build belt tension. 60-80 lbs is normal; err on the high end with the Photoman overdrive reduced diameter pulleys. I used my Gates cricket gauge to check progress. I got to 76 lbs and called it good

The large shiny head is the tension bolt lock bolt. The head of the tension bolt is under the pulley in this picture and accessed (with difficulty) from the side.

Phase 8: Torque bolts

-Top pivot bolt and the 7/16" bolt are 43 lb/feet

-Other bolts are 15 lb/ft.

Phase 9: Install electrical connectors

-Field connector installs using a 10mm nut. Get the cover boot back over

-I used the Photoman 3 to 4 adapter cable. Incredibly easy: the 4 port connector goes into the alternator and the existing 3 pin connector plugs into the 4" long adapter harness. I originally planned on repinning the connector but plug and play won the day here. Click click. Done.

Phase 10: Button it up.

-REINSTALL your oil filter! It will be a HUGE mess if you fail to do this. I taped the keys to the filter to ensure I did not forget this step.

-Reconnect coil wire to cap

-Reconnect the ground wire that goes fender to intake manifold

-Reinstall power steering reservoir. I went with 24 lb/feet on the bolts

-Reinstall battery box

-Install battery and clamp down

-Reconnect battery

-Reconnect overflow hose to top of radiator

Phase 11: FOD Check and QC

-Double check your oil filter is in place

-Do a through scan for tools and hardware left in the engine compartment

-Start the engine. Revel in the charge light being out and the ammeter showing a nice strong number

-Check your system voltage. Bask in your 14.1 volt glory

-Pack up the tools. Head back to the parts store with your old alternator in the box to get your core credit

Last edited: