I have been in the process of upgrading my front axles from 27 spline longs to 30 spline and while I was there I would clean, replace all seals and new studs for the high steer arms. I also reinforced the knuckle (because it likes to bend there) with a new shock mount from Marlin.

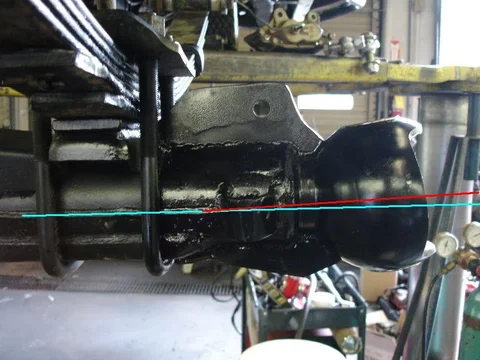

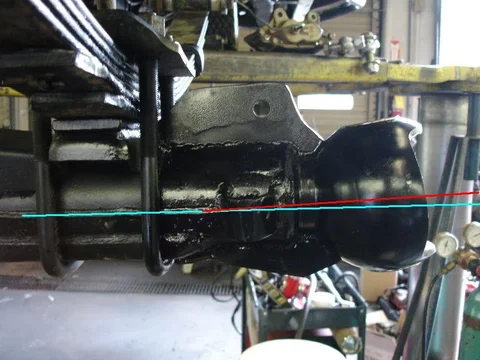

I noticed that I was having big problems getting the longfield to clear at the bottom of the knuckle housing, and when I installed just the axle it would bind on the seal.

It now explains strange noises that I heard and why the axle came out of the longfield and stripped, and that I had to use a slide hammer to get the axle out of the housing.

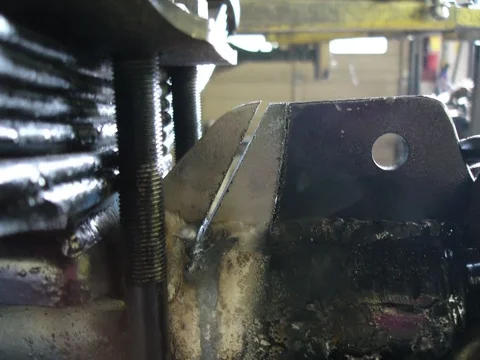

Problem is that I just reinforced a already bent housing and didn't know it at the time.

Nice new gusset with shock mount

This is the new axle in the bent housing, the axle is smashing the seal down. I cant even push the axle up and I had to use a dead blow hammer to get it all the way in.

Kiss that seal goodbye.

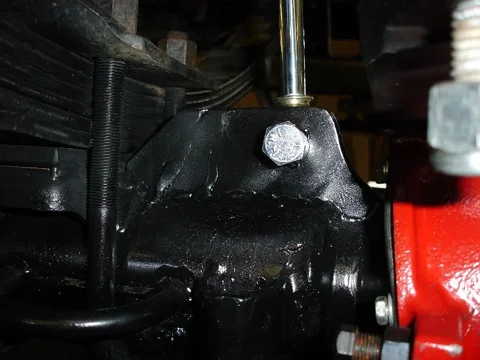

Wonder why this side was leaking so much

After a entertaining thoughts about dana 60s I wasn't going too give up all that work that I had put into that axle and was determined to fix it.

Turns out that the shock mount that was supposed to strengthen it was going to help me bend it back.

I noticed that I was having big problems getting the longfield to clear at the bottom of the knuckle housing, and when I installed just the axle it would bind on the seal.

It now explains strange noises that I heard and why the axle came out of the longfield and stripped, and that I had to use a slide hammer to get the axle out of the housing.

Problem is that I just reinforced a already bent housing and didn't know it at the time.

Nice new gusset with shock mount

This is the new axle in the bent housing, the axle is smashing the seal down. I cant even push the axle up and I had to use a dead blow hammer to get it all the way in.

Kiss that seal goodbye.

Wonder why this side was leaking so much

After a entertaining thoughts about dana 60s I wasn't going too give up all that work that I had put into that axle and was determined to fix it.

Turns out that the shock mount that was supposed to strengthen it was going to help me bend it back.

destroyed my gas mileage... oh wait what gas mileage.

destroyed my gas mileage... oh wait what gas mileage.