Vae Victus

Posting more than I know

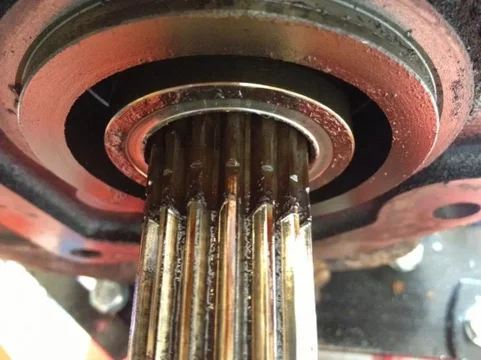

I am separating my transfer case from my transmission, and it is being stubborn. I built a puller from what bits I have about, and got it all welded up finally (don't laugh, I'm no machinist. Ran out of Argon mix too, so welds are really splattery and not penetrating well).

That's a crescent wrench hanging off the bolt btw.

Turning the carriage bolt is not pushing the shaft out of the case. The nut was actually separating from the square tube where it holds the bolt in - had to re weld it.

Is there something wrong with my design (besides the obvious lack of skill)? Are the bearings supposed to stay in the transfer case, or do the need to be able to come out too? I.e is my puller blocking them in?

That's a crescent wrench hanging off the bolt btw.

Turning the carriage bolt is not pushing the shaft out of the case. The nut was actually separating from the square tube where it holds the bolt in - had to re weld it.

Is there something wrong with my design (besides the obvious lack of skill)? Are the bearings supposed to stay in the transfer case, or do the need to be able to come out too? I.e is my puller blocking them in?