...Can I continue with the separator that is factory on the BJ60? ...

Separator?

I don't see any problem with leaving your original old BJ60 sedimenter in place in the fuel supply line to your new Dyna rotary pump (if that's what you're asking).

....That way I don't need the special fitting and filters if I convert the primer pump to a water separator.....

Sorry I get confused easily.

I'm guessing you have your original BJ60 sedimenter in place (slung underneath on a chassis rail or wherever Toyota put it) and your primer pump and filter went awol as soon as you removed your old 3B (that suffered "a leg out of bed").

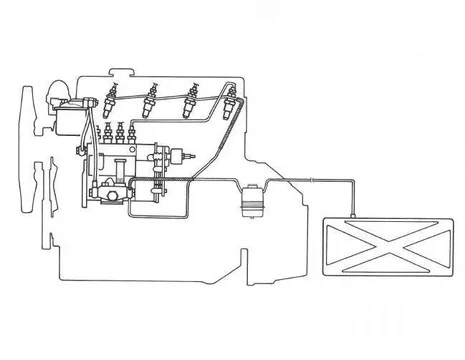

So you've bunged in your new Dyna 3B engine and you find it is without any inbuilt fuel-filter or inbuilt primer pump (because Toyota mounted those off-the-motor in the Dyna it came from).

Well then I think the solution for you is to find "a fuel filter with inbuilt primer pump" and fit it in your engine bay so you end up with fuel going from your tank, through your sedimenter, through your fuel filter and into your rotary IP and retain the ability to bleed out trapped air after filter cartridge changing.

PS. If your old sedimenter was working fine, or more importantly, not leaking, then there's certainly no need to remove it. It doesn't restrict fuel flow. AFAIK it just collects water and other "sediments" (that are heavier than diesel) that get trapped in the bottom of its "catcher".

PPS. My BJ40 has no sedimenter. But that's fine for me because our diesel is pretty clean in this country and a fuel filter cartridge serves the same purpose (but to a lesser extent ... unless it's a particularly long one) anyway in addition to its filtration job.

PPPS. Avoid mounting the "fuel-filter-primer-combo" lower than the connecting fuel lines because that will make it hard to get rid of the air that would infiltrate the fuel lines during filter changes. (But I'm probably wasting my time saying this because not many people would consider mounting such a thing low anyway.)