anyone got this thing? is it for greasing the bearings in the wheels or what was it for exactly? recommended?

THANKS

THANKS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Wheel bearings ride the spindle.

This greases either your bronze solid inner bush or the later needle bearing as it pushes grease into the birf cage.

Kinda exactly as described.

I’d buy one if I had birf soup & needed a easy band-aid way to keep good grease going in my knuckles until I could repair it.

That said, as a precaution I’d pop the pipe plug from the knuckle before pumping grease with the fitting, just so I didn’t pressure-pop the inner seal any worse than it already was in a state of.

Otherwise, I personally am fine just adding a few pumps via that top pipe plug.

But that’s just me.

I just swap the wheel bearings when I do a FAS - you’re literally right there. Then, depending on tire size/how well I hit my preload & if my inner seals need work again, I’ve only re-used wheel bearings if I botched a seal (I installed a new inner shaft, didn’t de-burr the seal area, rookie move).

So I’m 5/6 on seal installs, that one time I ate a seal in like 5K miles to full birf soup/greased inner tire sidewall ‘sunflower’.

Other than that one time, wheel bearings and seals are cheap for how messy & labor intensive FAS is - not cost effective to reuse any other time than emergency/trail repair situations.

Planned outage = new wheel bearings & seals, every time.

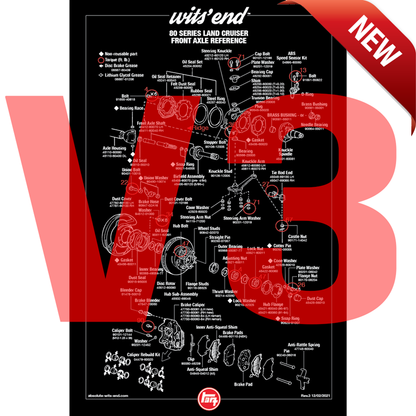

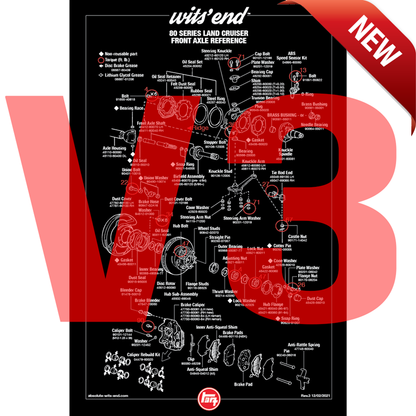

80 Series Front Axle Reference Poster- 18"x27", Version 3

80 Series Front Axle Reference Poster- 18"x27", Version 3 (REF-1)absolute-wits-end.com

This is also in your FSM.

Diannoo! - (however you spell that word of ‘cosmic alignment‘)

Pics I saw just now from a rig being worked - fits for you, and a shameless plug of a rig I dig:

View attachment 2136034

where you’re headed in a FAS:

View attachment 2136035

last pic shows how the knuckle chamber is separate from wheel bearings / grease seals that are divorced from wheel bearing grease / function.

Esp note the “flashcard” taped to the fender - that’s how smarter than me guys do.

I copied my paper FSM onto 11x17” paper at the local Kinko /office joint, had those hanging on the wall.

His way > my old way.

Everything you need for the front axle rebuild is in one kit that @cruiseroutf supplies.

BTW - Wiser ones than myself have questioned the need of replacing wheel bearings every time the front axle is serviced.

Rather - inspect and replace w new only if signs of aging are there, otherwise, just replace the old ones in good shape.

Reason - If wheel bearings are kept properly preloaded and greased, then they have no specific lifespan.

You could say they last indefinitely. Not forever, mind you, but a long time, 100k miles? 200k? Not predictable.

If it aint broke, don't fix it, as they say.

Also, it's not trivial in cost or effort. I's not a huge, huge job, but it's certainly not nothing.

It does take time and effort to pound out the outer bearing race with a brass drift.

There's some chance of screw up, damage, or mis-seating in pounding in the new race.

So - you voluntarily introduce some risk to an already stable situation.

That said, not too long after I first got the Landcruiser, I did do the full front axle rebuild, all bearings included.

Nothing at all was wrong with the old ones, Still have 'em. Call them spares, I guess.

Reason - Did it partly for the experience, having never done such work before, and partly for the reassurance of "known good shape" going forward, long term.

It's probably time for me to service the front axle again, but I won't replace the wheel bearings this time, unless needed.

I know for sure they've been treated well.

Think it through, decide what you want to do, but don't do it "just because"